Great Wall Hover. Manual - part 53

Upper suspension arm

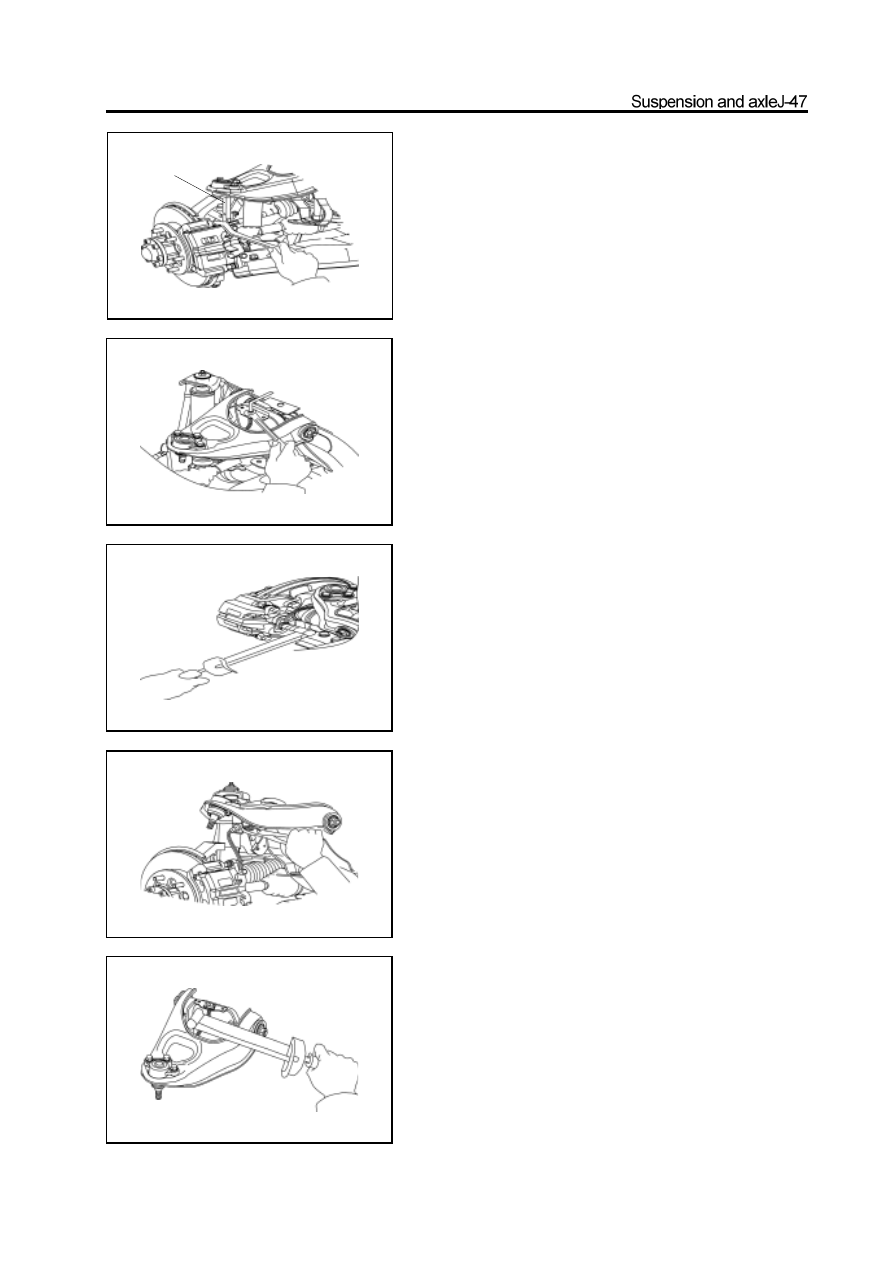

Disassembly of upper suspension arm

1. Disconnect the upper ball pin form the steering

knuckleRemove the split pin and nut; use the special

tools to disconnect the upper ball pin from the steering

knuckle.

2. Remove the brake oil pipe on the upper arm shaft

a. Use the open-end wrench to screw off the oil pipe tight nut.

b. Pull out the brake oil pipe and plug it by the rubber plug.

Remarks: There are two two-way valves for rear brake oil pipe

beside the right upper arm shaft ; when remove the right upper

suspension arm, it must remove four oil pipe tight nuts in the

place and plug it by the rubber plug to prevent the brake fluid

from overflowing.

3. Disconnect the brake hose form the brake caliper

Remove the hollow bolt and disconnect the brake hose

form the brake caliper

Remarks: Must not lose the copper gasket seal.

4. Disconnect the brake hose from the upper arm oil

pipe bracket.

Use the pliers to pull out the sheet steel spring clip and

disconnect the brake hose from the upper arm oil pipe

bracket.

5. Remove the upper suspension armRemove two bolts

and remove the upper suspension from the armcarriage.

Remarks: Keep the adjusting shim and don’t lose it. Record the

thickness of front and rear adjusting shim for convenience of

reinstalling them in the original position.

special tools