Great Wall Hover. Manual - part 51

Ball pin

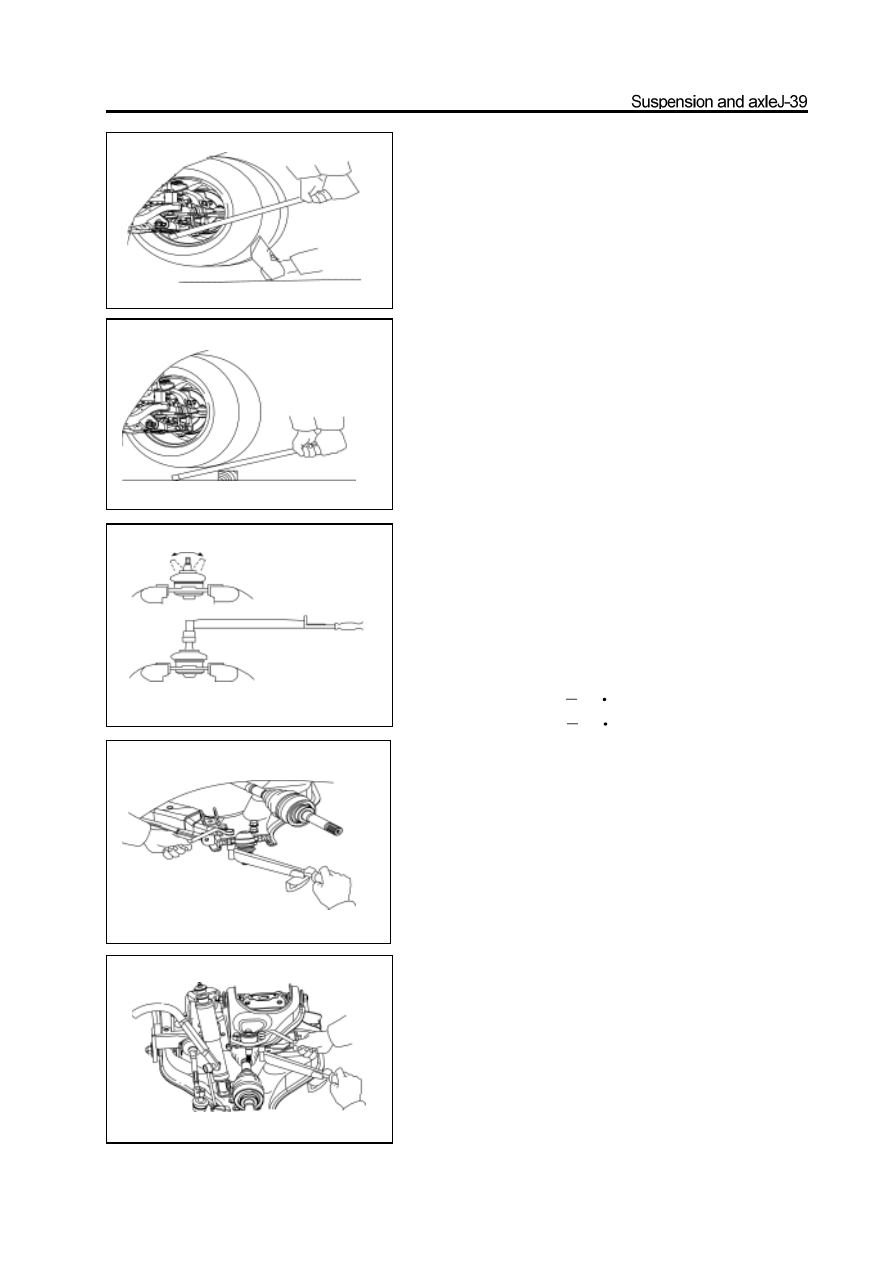

Check of ball pin

1. Check the lower ball pin for loose

a. Raise the front of the car by jack and support it by the frame.

b. Ensure the front wheel is in straight advancing position and step

down the brake pedal.

c. Move the arm upwardly and downwardly; check

the clearance of lower ball pin.

Max. vertical clearance: 0mm

2. Check the upper ball pin for loose move the wheel

upwardly and downwardly and check the gap of

upper ball pin.

Max. vertical clearance: 0mm

3. Check the rotation of ball pin

a. Remove the ball pin.

b. Shown as figure, shake the ball pin stud forwardly and backwardly

for several times before install the nut

c. Rotate the nut continuously by torsion meter and 2-4s for a

cycle; record the readout of torsion meter in the fifth cycle.

Tightening torque (for rotary):

Lower ball pin 0.1

4N

m

Upper ball pin 0.1

4N

m

Disassembly of ball pin

1. Remove the steering knuckle and front hub assembly

(Refer to section “Front Hub and Steering Knuckle”)

2. Remove the lower ball pin form the lower arm

3. Remove the upper ball pin from the upper arm