Great Wall Hover. Manual - part 50

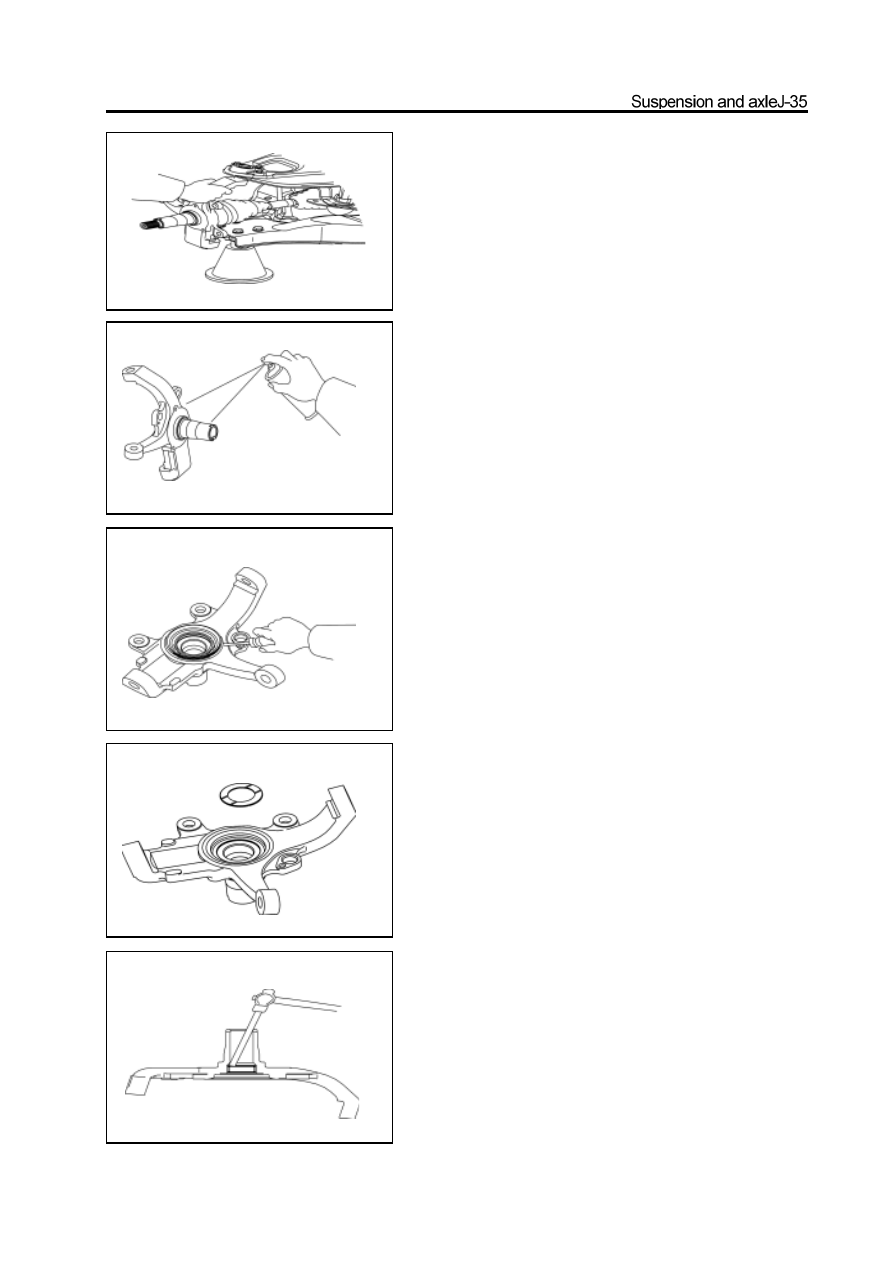

e. Use the jack to raise the lower arm; remove the steering knuckle.

Check and replacement of steering knuckle

1. Check of steering knuckle

Use the dye penetrant to check the steering knuckle for crack.

It should replace the steering knuckle if has crack.

2. Remove the steering knuckle oil seal

Use the screwdriver to pry out the oil seal from the steering knuckle.

3. Take out the thrust plate

4. Remove the needle bearing

Use the copper bar and hand hammer to knock out the needle

bearing.