Great Wall Hover. Manual - part 11

b. Remove the lower cover plate assembly

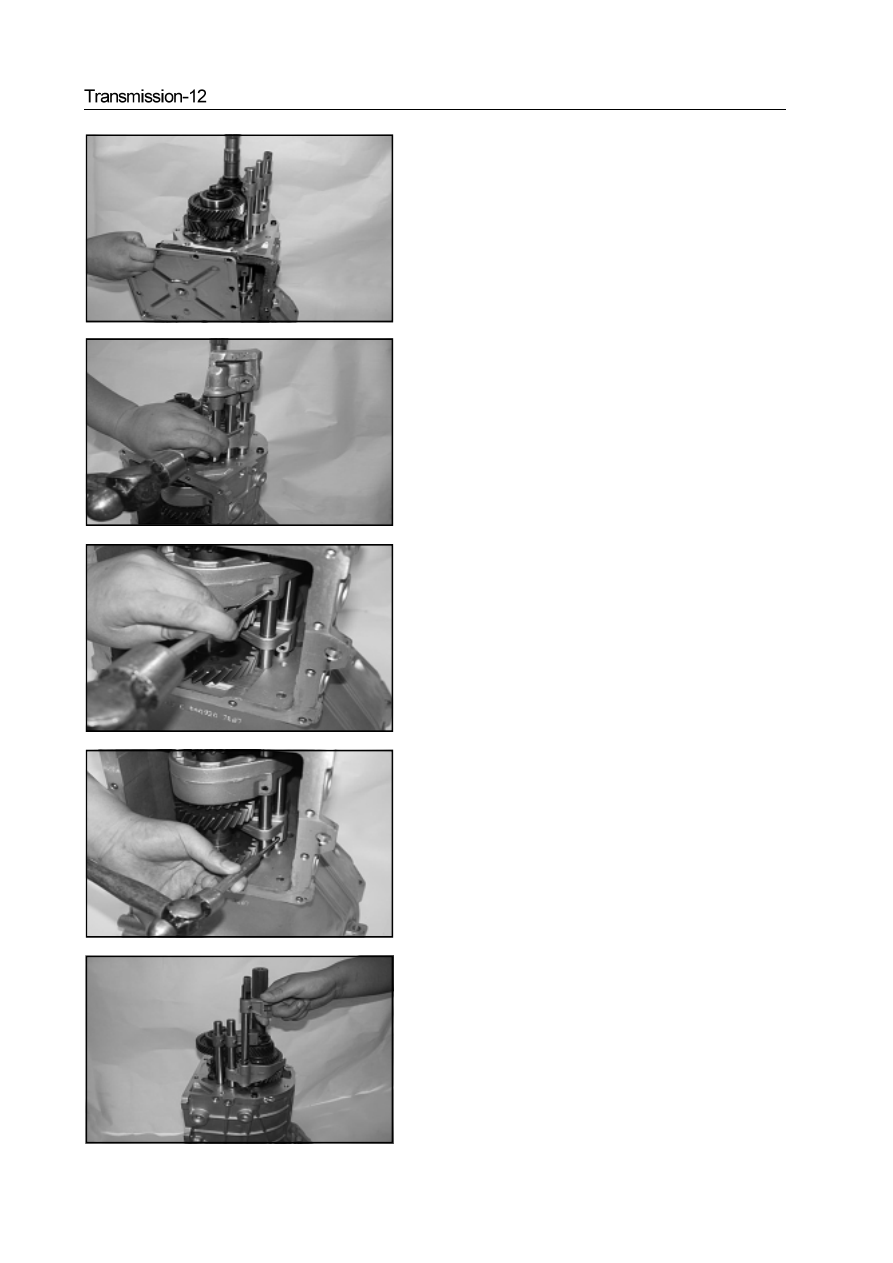

17. Remove the declutch shift shaft assembly

a. Use the punch to remove the reverse gear 5 shift fork elastic

cylindrical pin

b. Use the punch to remove the Gear 1/2 shift fork elastic cylindrical

pin

c. Use the punch to remove the Gear 3/4 shift fork cylinder pin.

d. Remove the reverse gear 5 declutch shift shaft assembly