Great Wall Hover. Manual - part 10

N

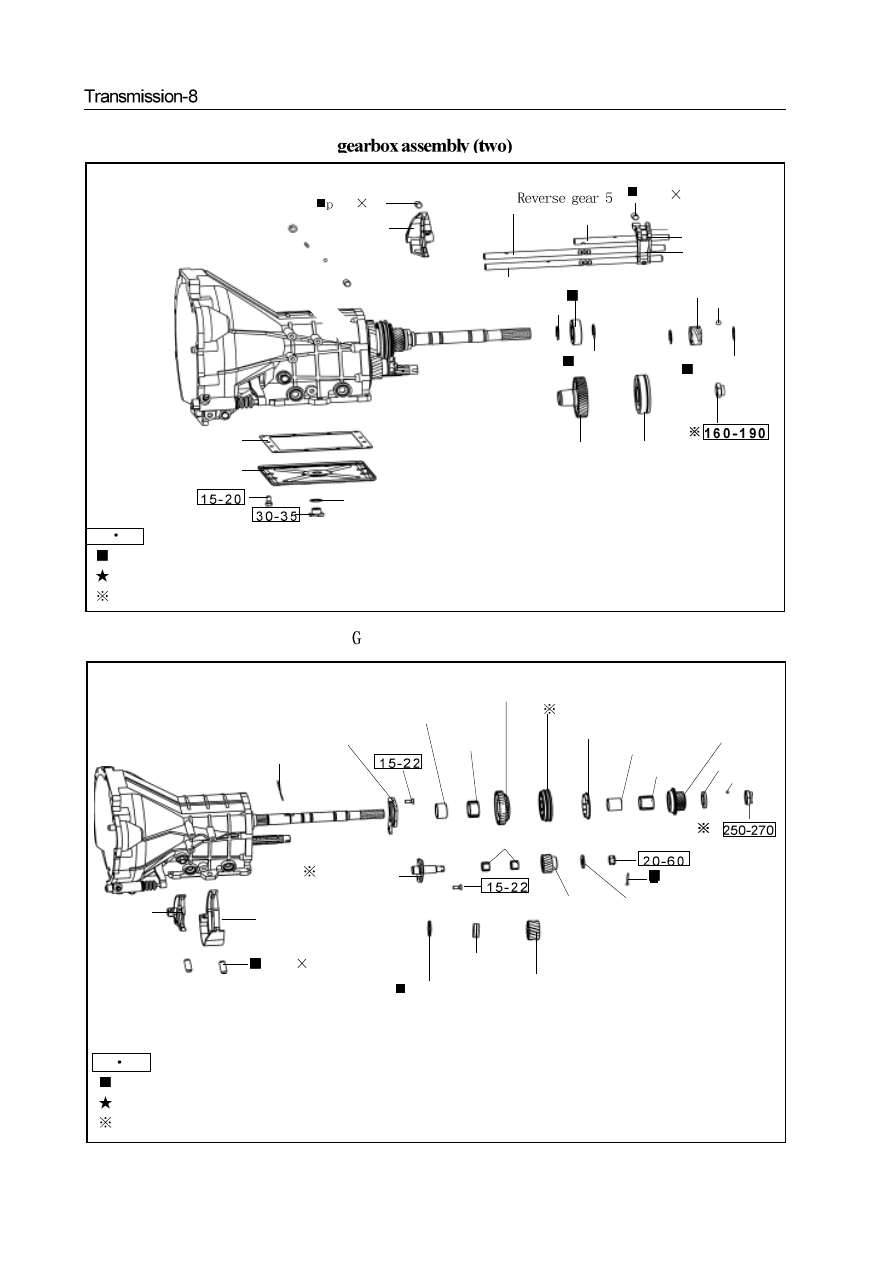

m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

aluminum

washer

lower cover plate assembly

bush

gear 5 drive gear ball bearing

circlip for shaft

steel ball

odometer drive gear

circlip for shaft

ball bearing

circlip for shaft

reverse gear 5

shift fork

in 6

22

declutch shift shaft for

first and secondea

gear 3/4 declutch

shift shaft

declutch shift shaft

pin 5

22

gear 1/2 shift-

ing block

gear 3/4 shifting

block

earbox assembly (three)

steel ball 4.762

pin 6

22

gear 1/2 shift fork

adjusting shim

spacing ring

reverse drive gear

reverse shaft

needle bearing

reverse gear

thrust washer

split pin

grease baffle of air duct

support axial lock plate

reverse needle bearing bushing

needle bearing

thrust washer

gear 5 needle

bearing bushing

synchronizer gear ring

reverse gear 5 synchronizer assembly

N

m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

gear 3/4

shift fork

reverse driven gear assembly

needle bearing

gear 5 driven

gear assembly