Great Wall Hover. Manual - part 8

Clutch-9

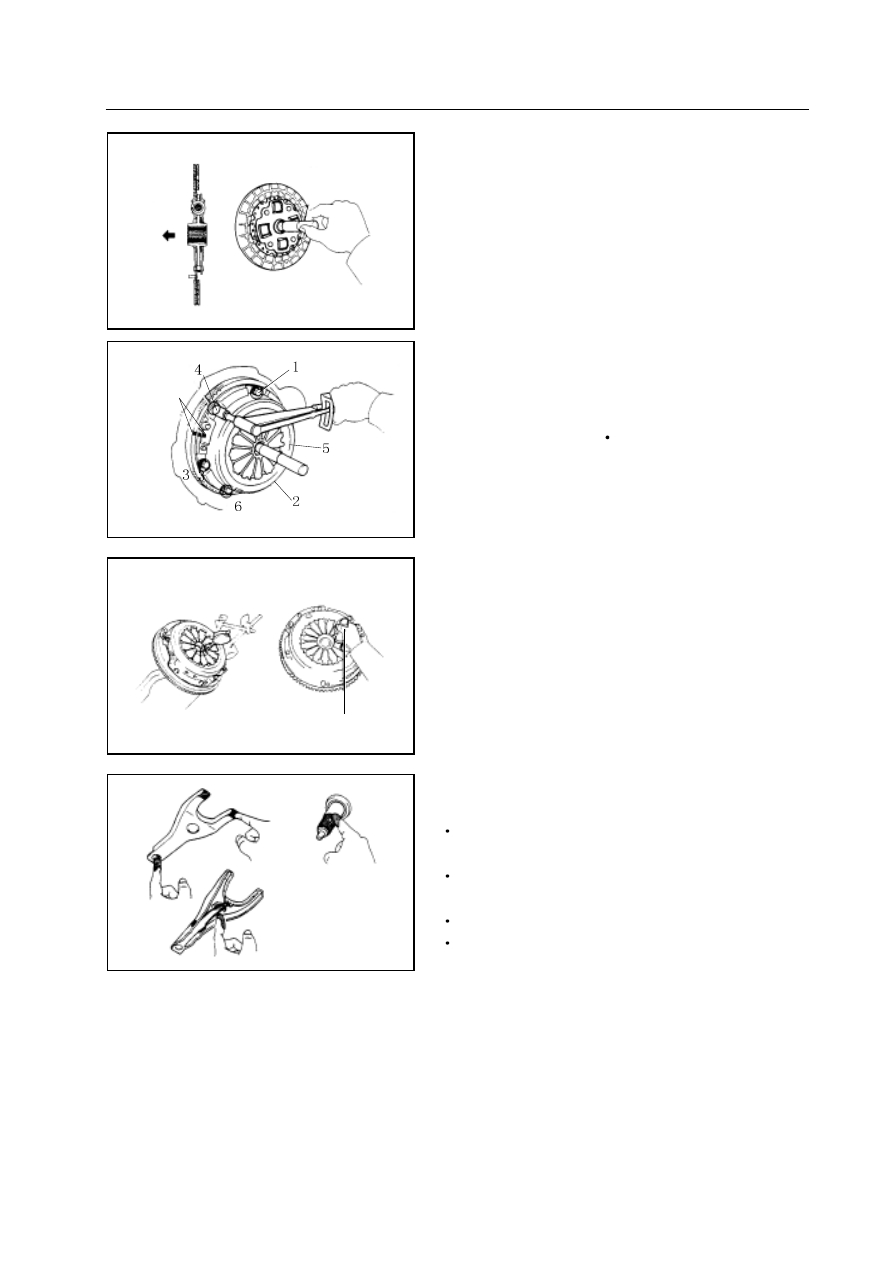

2.Installtion of clutch cover

a. Align the matching mark of clutch shell with that of flywheel .

b. Tighten the bolt evenly. Exert force along the edge of the clutch

cover repeatedly until binding tightly. Tighten the bolt.

Tightening force: 19N

m

Remarks: First tighten the upper most bolt of the 3 bolts

near the

location pin.

3. Check the end surface runout of diaphragm spring clutch finger.

Use the special tools to check the alignment of diaphragm spring.

Maximum displacement: 0.5mm

If the displacement is greater than the specified value, use the special

tools to adjust the face runout amount of the diaphragm spring clutch

finger.

4. Coat the following components with the molybdenum disulfide

lithium base grease (NLGI NO.2) or multi-purpose grease :

contacting point of separation rocker arm assembly and bearing

bush

contacting point of separation rocker arm assembly and subcylinder

push bar

separation rocker arm assembly supporting point

gear box 1

st

axle spline

5. Install the leather cup, separation rocker arm assembly, clutch

cover assembly and throwout bearing in the transmission.

6. Install the transmission

matching mark

Installation of clutch

1.Install the clutch disc on the flywheel

Use the special tools to install the clutch disc on the flywheel.

special tools