Great Wall Hover. Manual - part 7

Clutch-5

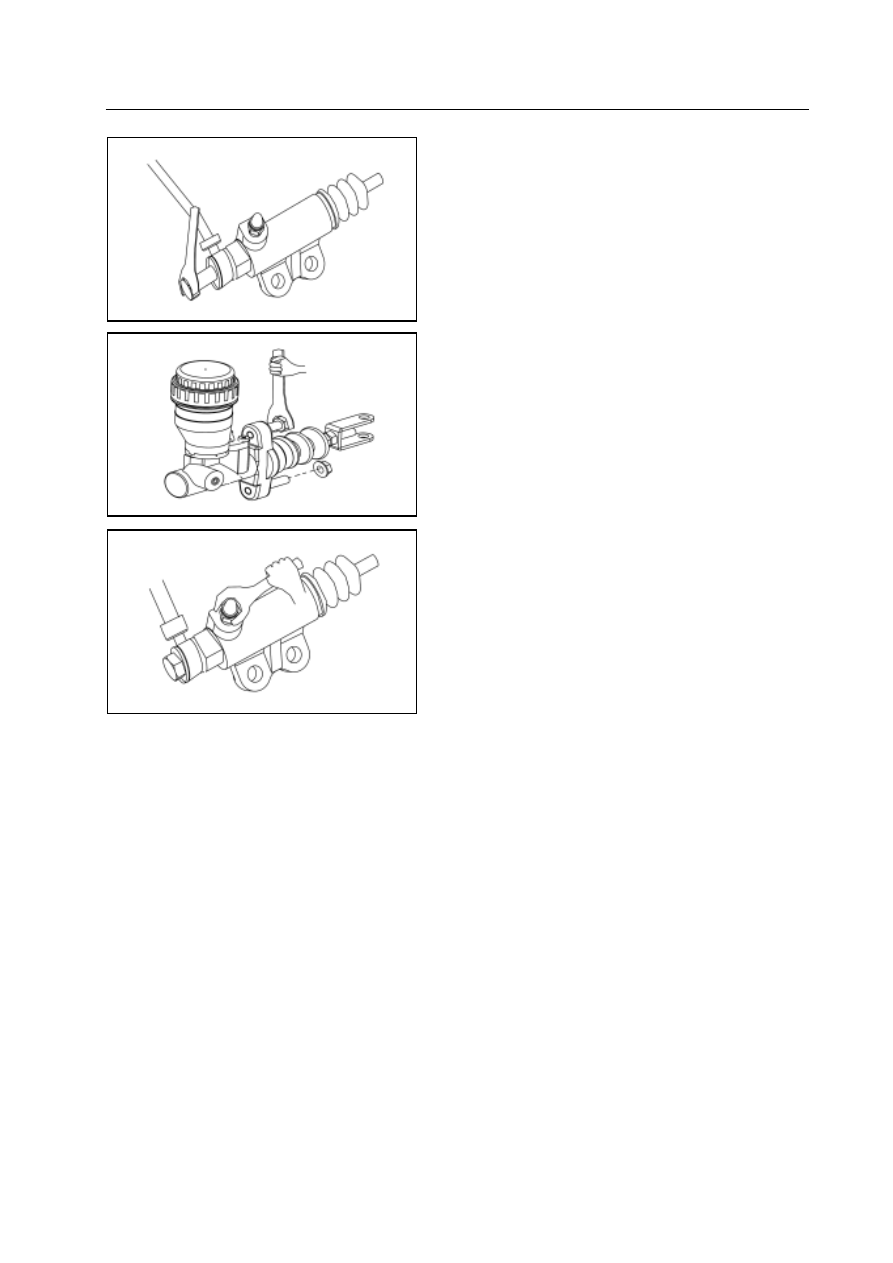

Removal of clutch master cylinder, clutch cylinder

1. Use the No. 16 open-end wrench to remove the hose connecting

bleed bolt, use the cloth to cover the oil outlet of auxiliary pump

to avoid the splash of 0brake fluid; step on the clutch pedal for

several times to drain the clutch.

Cautions for installation of clutch operation device:

1. Installation of clutch hard pipe : Check the hard pipe for

deformation, check to see whether the curling at the port of

connection pipe is complete and without damage, if there is no

problem after confirmation, it can be installed and fixed in the

front wall clip and hard-tube clip.

2. Coat each rotary parts of peal with the lithium base grease.

3. Check the surface of clutch hoes, no surface cracking, oil leakage

and dog leg is allowed, use the split washer and spring clip to fix

the clutch hose on the support frame of car body.

4. Connect the joints of the general pump oil pipe and the general

2. Remove the split pin and cylinder pin connected the master

pump connecting fork to the pedal; use the No. 13 socket spanner

to remove two nuts Q32008 which is used to install the master

pump. Check the clutch master cylinder, replace the complete

master pump if the internal of master pump has the abnormal

noise and damage of leakage etc.

pump and sub pump according to the required tightening torque.

5. The air in the clutch oil path needs to be exhausted after filling

oil (except the vacuum filling): step on the clutch pedal after

filling the oil tank, when feeling difficult in stepping, use the

open-end wrench with specification of 11 to loosen the air bleed

plug screw to exhaust the air, then tighten the plug screw,

repeat the operation for several times. Tighten the air bleed

plug screw of the sub pump when there is no foam in the

flowing oil liquid. Supplement the oil of the oil tank to the

level between the Max and the Min.