Snowmobile Arctic Cat (2008 year). Manual - part 110

6-84

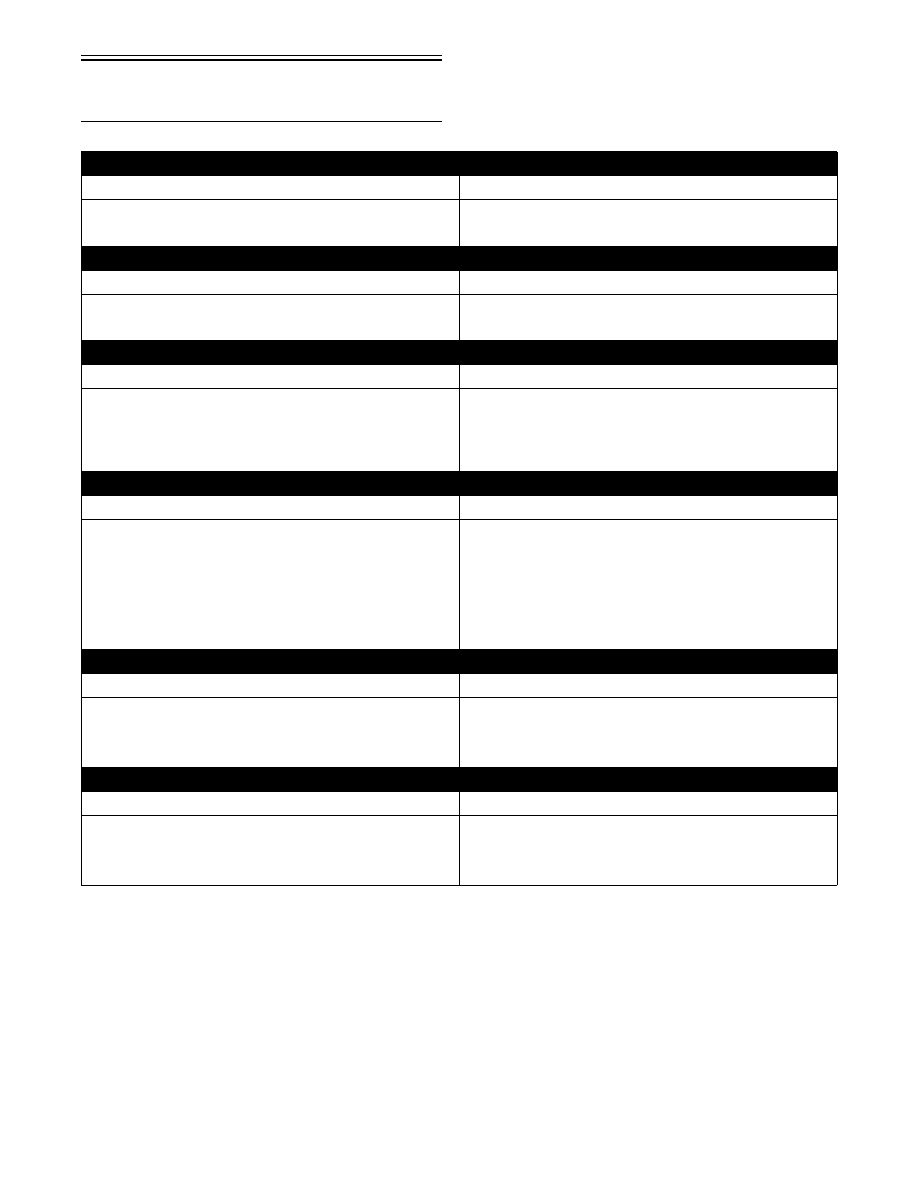

Troubleshooting

Hydraulic Brake System

Problem: Caliper Leaks

Condition

Remedy

1. Caliper O-ring deteriorated — severed

1. Replace O-ring

2. Piston — O-ring damaged

2. Repair piston — replace piston — O-ring

Problem: Lever Spongy — Bottoms Out

Condition

Remedy

1. Brake system air bubbles present

1. Bleed brake system

2. Master cylinder damaged — faulty

2. Replace master cylinder

Problem: Oscillation Feedback in Lever

Condition

Remedy

1. Brake pad residue present on brake disc

1. Replace pads — clean disc

2. Caliper loose

2. Tighten mounting bolts

3. Brake disc warped — cracked — damaged — mis-

aligned

3. Replace disc — driven shaft bearing

Problem: Loss of Brake

Condition

Remedy

1. Brake fluid overheated — contaminated

1. Replace fluid

2. Master cylinder damaged — faulty

2. Replace master cylinder

3. Caliper — brake hose leaking

3. Replace caliper O-ring — repair piston —replace pis-

ton — O-ring — brake hose

4. Air ducts obstructed — missing

4. Remove obstruction — replace air ducts

5. Brake lever linkage damaged

5. Repair — replace lever — mounting bolt

Problem: Brakes Drag

Condition

Remedy

1. Master cylinder damaged — faulty

1. Replace master cylinder

2. Brake disc warped — damaged — misaligned

2. Replace disc — driven shaft bearing

3. Brake pads worn — tapered

3. Replace pads

Problem: Snowmobile Won’t Stop — Have to Pull Too Hard on Lever

Condition

Remedy

1. Pads/brake disc glazed

1. Replace pads — clean disc

2. Brake lever binding

2. Loosen pivot bolt — replace master cylinder

3. Caliper pistons binding

3. Service caliper assembly