Snowmobile Arctic Cat (2008 year). Manual - part 67

3-12

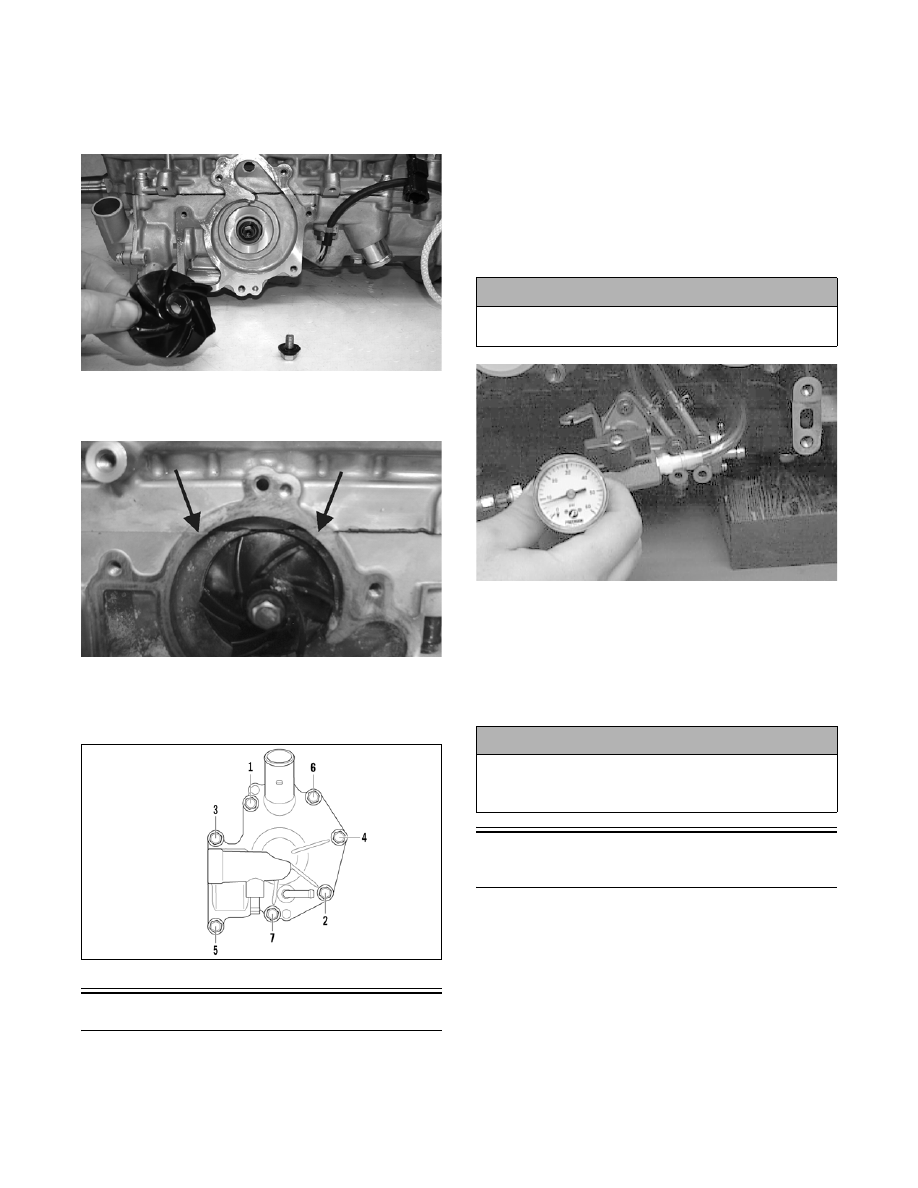

9. Place the impeller into position and secure with a

cap screw and washer. Be sure the rubber side of

the washer is directed towards the impeller. Apply

blue Loctite #243 to the threads of the cap screw

and tighten to 8 ft-lb.

FS225

10. Apply sealant to the crankcase seam; then install

the alignment pins into the crankcase (if removed).

FC133A

11. Position the O-ring into the water pump cover;

then install the cover. Install the cap screws; then

using the pattern shown, tighten to 8 ft-lb.

0742-257

Pressure Testing Engine

1. Test the engine for air leaks using the following

procedure and Engine Leak-Down Tester Kit.

A. Install a plug into each intake-manifold port

and tighten the flange clamps securely.

B. Place a rubber plug and cover on each exhaust

port and secure.

NOTE: On APV equipped engines, install the APV

cover plates.

C. Connect the tester pump to an impulse fitting

on the crankcase; then plug any remaining

impulse fittings and pressurize the crankcase to

8 psi and close the valve.

AN128D

D. Monitor the pressure gauge. The pressure must

not drop at a rate of more than 1 psi per minute.

E. If the pressure drops faster than specified,

inspect for an air leak with soapy water or by

completely submerging the pressurized engine

in clean fresh water. Repair as needed.

Liquid Cooling System

(500/600/800/1000 cc)

The liquid cooling system consists of heat exchangers,

water pump, coolant temperature sensor, and thermo-

stat. The system should be inspected for leaks or dam-

age whenever an overheating problem is experienced.

DRAINING COOLING SYSTEM

(Crossfire/M-Series)

1. Using a piece of cardboard to protect the hood and

belly pan, tip the snowmobile on its PTO-side.

2. From beneath the front end, remove the self-tap-

ping screws securing the skid plate to the chassis.

! CAUTION

DO NOT exceed 8 psi pressure or damage to the

seals will result.

! CAUTION

When submerging the engine to test for air leaks, all

external electrical components must be removed to

avoid damage.