Snowmobile Arctic Cat (2008 year). Manual - part 65

3-4

4. Rotate the fan drive pulley clockwise while

observing the other two holes in the pulley. When

they align with the two holes in the flywheel, start

the remaining two mounting cap screws.

5. Tighten the three cap screws only to position the

fan drive pulley on the flywheel; then remove the

three cap screws and install the recoil starter pul-

ley. Apply red Loctite #271 to the threads of the

three cap screws and install them into the fly-

wheel. Tighten the three cap screws evenly to 6-

9 ft-lb.

6. Check the fan belt tension. Adjust as necessary.

7. Install the fan cover and secure with six screws.

Tighten the screws to 8 ft-lb.

8. Install the recoil starter. Secure with four cap

screws. Tighten to 8 ft-lb.

REPLACING FAN BELT

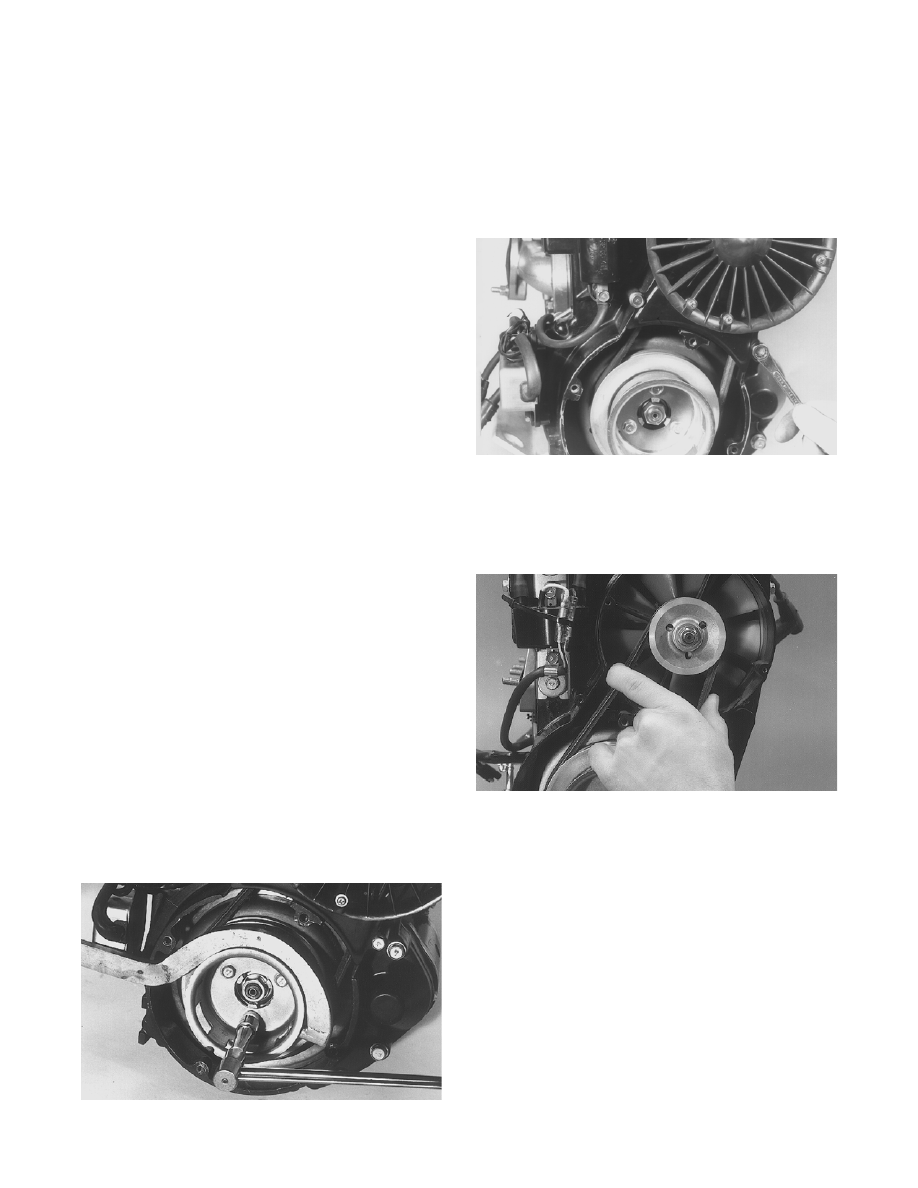

1. Remove the fan cover and the recoil starter.

2. Remove the three cap screws securing the recoil

starter pulley and the fan drive pulley to the fly-

wheel.

3. Remove the fan drive pulley and fan belt from the

engine.

4. Place the new fan belt into position on the upper

pulley.

5. Place the fan drive pulley onto the fan belt and

align one of its holes with one of the mounting

holes in the flywheel; then start a cap screw into

the aligned hole and finger-tighten.

6. Rotate the fan drive pulley clockwise while

observing the other two holes in the pulley. When

they align with the two holes in the flywheel, start

the remaining two cap screws.

7. Tighten the three cap screws only to position the

fan drive pulley on the flywheel; then remove the

three cap screws and install the recoil starter pul-

ley. Apply red Loctite #271 to the threads of the

three cap screws and install into the flywheel.

Tighten the three cap screws evenly to 10 ft-lb.

AB040

NOTE: With the new belt installed, check fan belt

tension (see Checking Belt Tension).

8. Install the fan cover. Tighten the screws to 8 ft-lb.

Install the recoil starter. Tighten the cap screws to

8 ft-lb.

CHECKING BELT TENSION

1. Remove the fan cover.

AB075

2. Squeeze the belt at midspan and observe the belt

deflection. The maximum belt deflection on either

side must not exceed 6 mm (1/4 in.). If the deflec-

tion is not within specifications, adjust the belt

tension.

B075

3. Install the fan cover. Tighten the screws to 8 ft-lb.

ADJUSTING BELT TENSION

1. Remove the fan cover.

2. Using the fan spanner wrench, remove the nut,

lock washer, and washer securing the pulley

halves.

3. Slide the outer pulley half off the shaft and

account for any shim(s).

4. Add or remove shim(s) to attain correct belt ten-

sion.

NOTE: To increase belt tension, remove shim(s);

to decrease belt tension, install shim(s).