Snowmobile Arctic Cat (2008 year). Manual - part 66

3-8

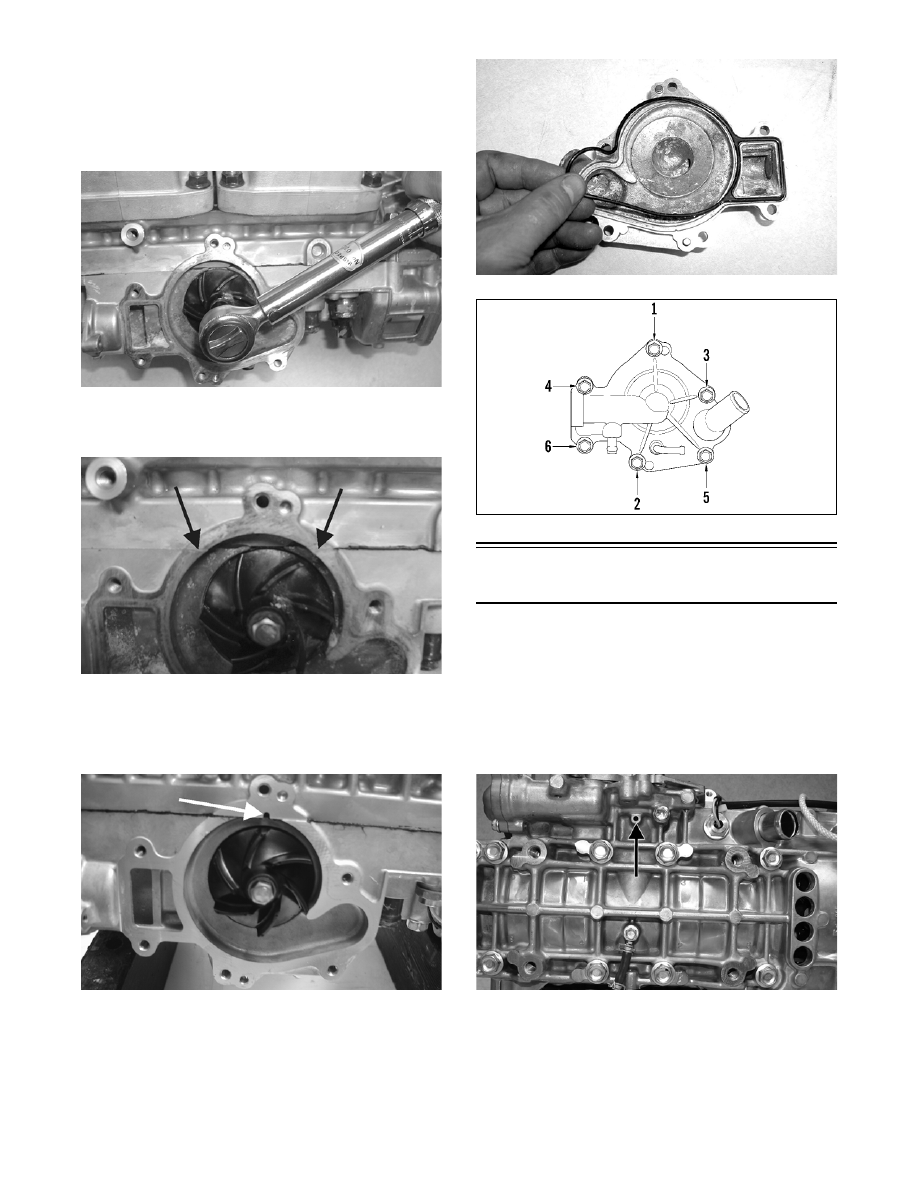

10. Place the impeller into position and secure with a

cap screw and washer. Be sure the rubber side of

the washer is lubricated with a fine coat of oil and

directed towards the impeller. Apply blue Loctite

#243 to the threads of the cap screw and tighten to

6-9 ft-lb.

FC132

11. Apply sealant to the crankcase seam; then install

the alignment pins into the crankcase (if removed).

FC133A

NOTE: It is important to not get sealant into the

breather hole in the crankcase. If sealant gets into

the hole, carefully remove before proceeding.

FC072B

12. Position the O-ring into the water pump cover;

then install the cover. Install the cap screws; then

using the pattern shown, tighten to 8 ft-lb.

FC134

0742-304

Repairing Water Pump

(800/1000 cc)

NOTE: The engine must be removed for this pro-

cedure (see Section 2).

NOTE: A bleed hole is located in the crankcase

beneath the water pump housing. If there are any

signs of coolant leakage from the bleed hole, the

water pump seals must be replaced.

FS219A

NOTE: When servicing the water pump, use

Water Pump Bearing and Seal Tool Kit and Oil Seal

Protector Tool.