Snowmobile Arctic Cat (2008 year). Manual - part 68

3-16

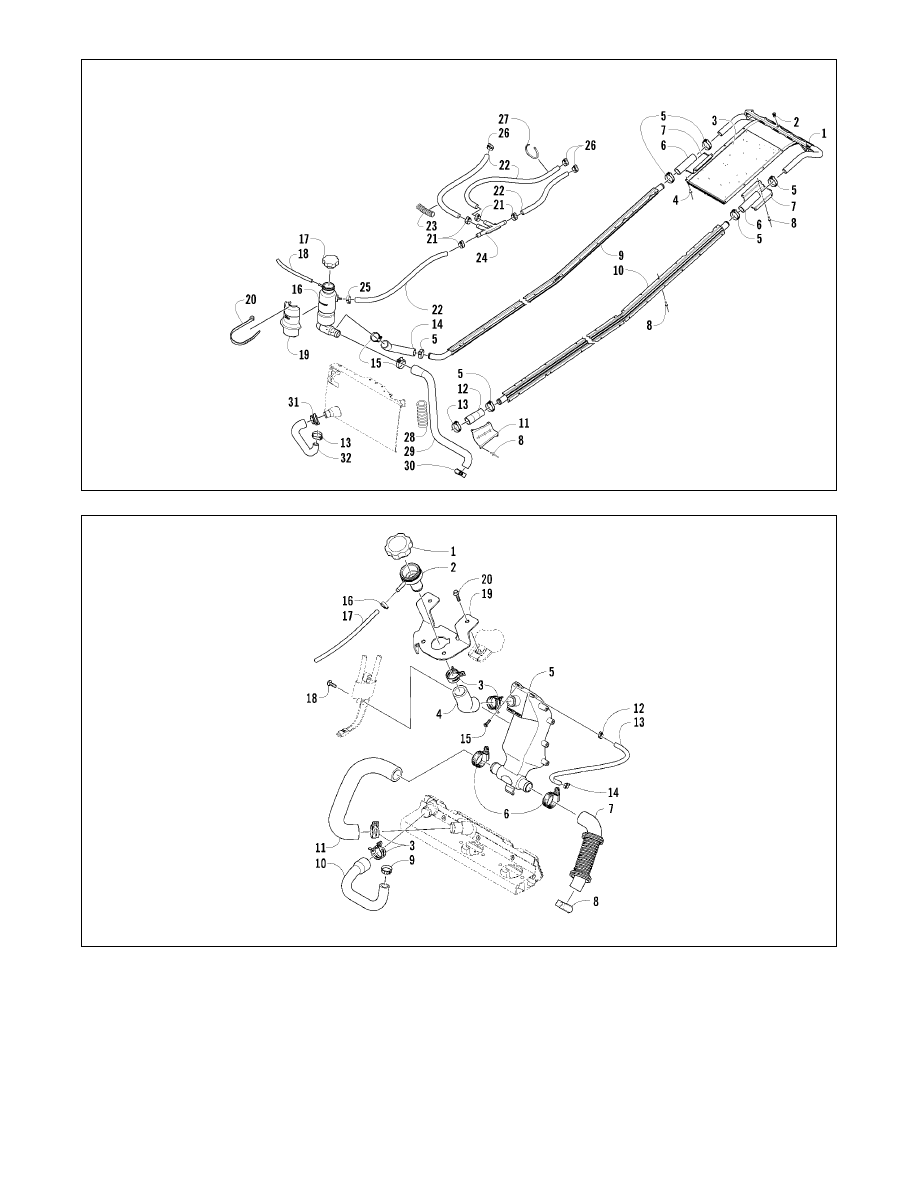

0742-120

0741-835

KEY

1. Rear Heat Exchanger

2. Insert

3. Foam

4. Rivet

5. Hose Clamp

6. Hose

7. Hose Protector

8. Rivet

9. Heat Exchanger

10. Heat Exchanger

11. Hose Protector

12. Hose

13. Hose Clamp

14. Hose

15. Hose Clamp

16. Coolant Tank

17. Cap

18. Hose

19. Heat Shield

20. Cable Tie

21. Hose Clamp (1000 cc)

22. Hose

23. Loom (1000 cc)

24. Fitting (1000 cc)

25. Hose Clamp

26. Hose Clamp (1000 cc)

27. Cable Tie (1000 cc)

28. Hose Protector

29. Hose

30. Hose Clamp

31. Hose Clamp

32. Hose

Crossfire/M-Series

KEY

1. Cap

2. Filler Neck

3. Clamp

4. Hose

5. Coolant Tank

6. Clamp

7. Hose

8. Clamp

9. Clamp

10. Hose

11. Hose

12. Clamp

13. Hose

14. Clamp

15. Machine Screw

16. Clamp

17. Hose

18. Self-Tapping Screw

19. Bracket

20. Cap Screw

F-Series 500/600/T500