Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 755

Test Sequence:

Note

The output diagnostic test mode checks the fuel pump function.

– Pay attention to all safety precautions. Refer to

⇒ “1 Safety Precautions”, page 1

.

– Follow the guidelines for clean working conditions. Refer to

⇒ “3.1 Parking/Auxiliary Heater and Fuel System Clean Work‐

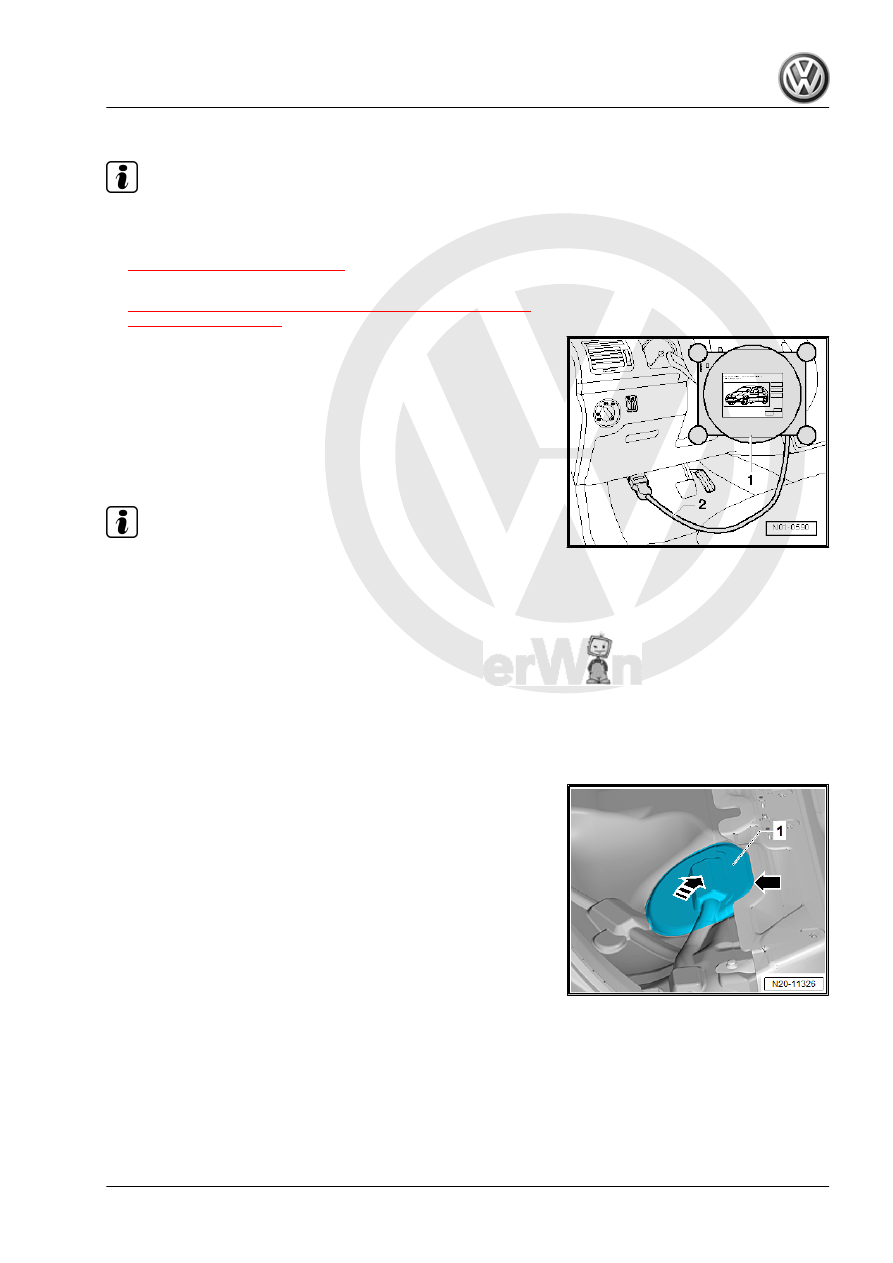

– Connect the Vehicle Diagnostic Tester -1- as follows:

– Connect the diagnostic cable connector -2- to the diagnostic

connection inside the driver footwell.

– Switch the ignition on.

– Select the fuel pump output diagnostic test mode in OBD.

The fuel pump must now accelerate slowly up to the maximum

RPM.

Note

♦

The fuel pump runs very quietly.

♦

If the output diagnostic test mode is performed several times

in succession, it may be necessary to briefly start the motor

before repeating the output diagnostic test mode.

– Switch off the ignition.

If the fuel pump does not start:

Golf Sportsvan:

– Remove the right rear seat. Refer to ⇒ Body Interior; Rep. Gr.

72 ; Rear Seats; Bench Seat / Single Seat, Removing and In‐

stalling .

– Partially loosen the cover -1- in the carpet at the separating

line -arrow-.

– Do not separate the cover completely from the carpet so that

later it will be installed correctly.

– Only loosen so far that the cover can be folded up.

– Fold up the cover in the direction of the -arrow-.

Golf and Golf Wagon:

– Remove the rear bench seat. Refer to ⇒ Body Interior; Rep.

Gr. 72 ; Rear Seats; Bench Seat / Single Seats, Removing

and Installing .