Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 756

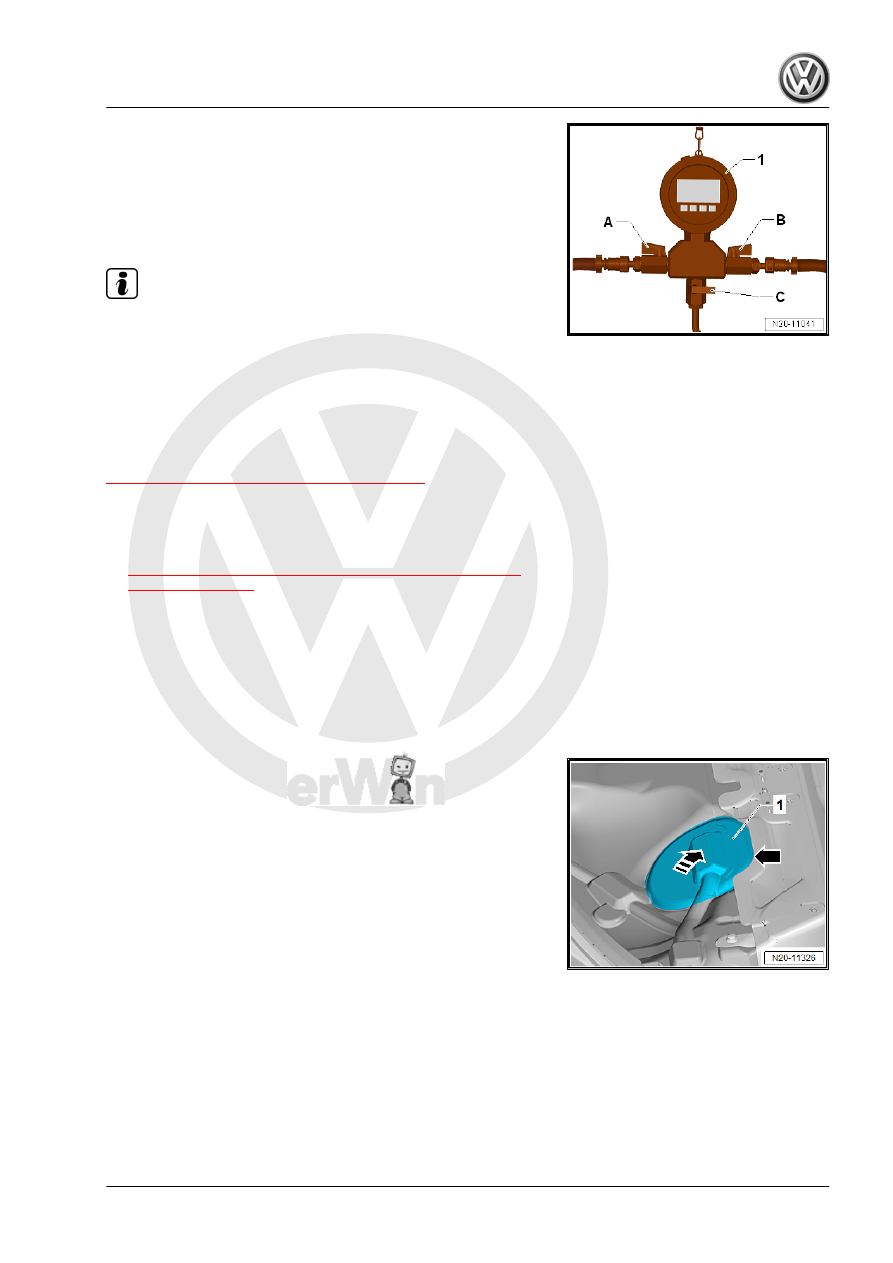

– Make sure that the drain valve -C- on the Pressure Tester

-1- is closed.

– The shut-off valves -A- and -B- on the Pressure Tester Kit -

VAS6550- -1- are opened.

– Connect the Vehicle Diagnostic Tester .

– Select the fuel pump output diagnostic test mode in OBD.

Note

♦

The fuel pump is now activated to build up the fuel pressure.

♦

If the output diagnostic test mode is performed several times

in succession, it may be necessary to briefly start the motor

before repeating the output diagnostic test mode.

– Read the fuel pressure on the pressure gauge.

• Specified value: 4.0 to 7.0 bar.

If the fuel pressure is OK, check the residual pressure. Refer to

⇒ “8.1.5 Residual Pressure, Checking”, page 95

If the specified value is exceeded:

– The pressure relief valve in the fuel delivery unit is faulty.

– Replace the fuel delivery unit. Refer to

⇒ “2.2 Fuel Delivery Unit/Fuel Level Sensor, Removing and

.

If the specified value is not obtained:

Proceed as follows to check the fuel pressure at the fuel delivery

unit:

Golf Sportsvan:

– Remove the right rear seat. Refer to ⇒ Body Interior; Rep. Gr.

72 ; Rear Seats; Bench Seat / Single Seat, Removing and In‐

stalling .

– Partially loosen the cover -1- in the carpet at the separating

line -arrow-.

– Do not separate the cover completely from the carpet so that

later it will be installed correctly.

– Only loosen so far that the cover can be folded up.

– Fold up the cover in the direction of the -arrow-.

Golf and Golf Wagon:

– Remove the rear bench seat. Refer to ⇒ Body Interior; Rep.

Gr. 72 ; Rear Seats; Bench Seat / Single Seats, Removing

and Installing .