Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 691

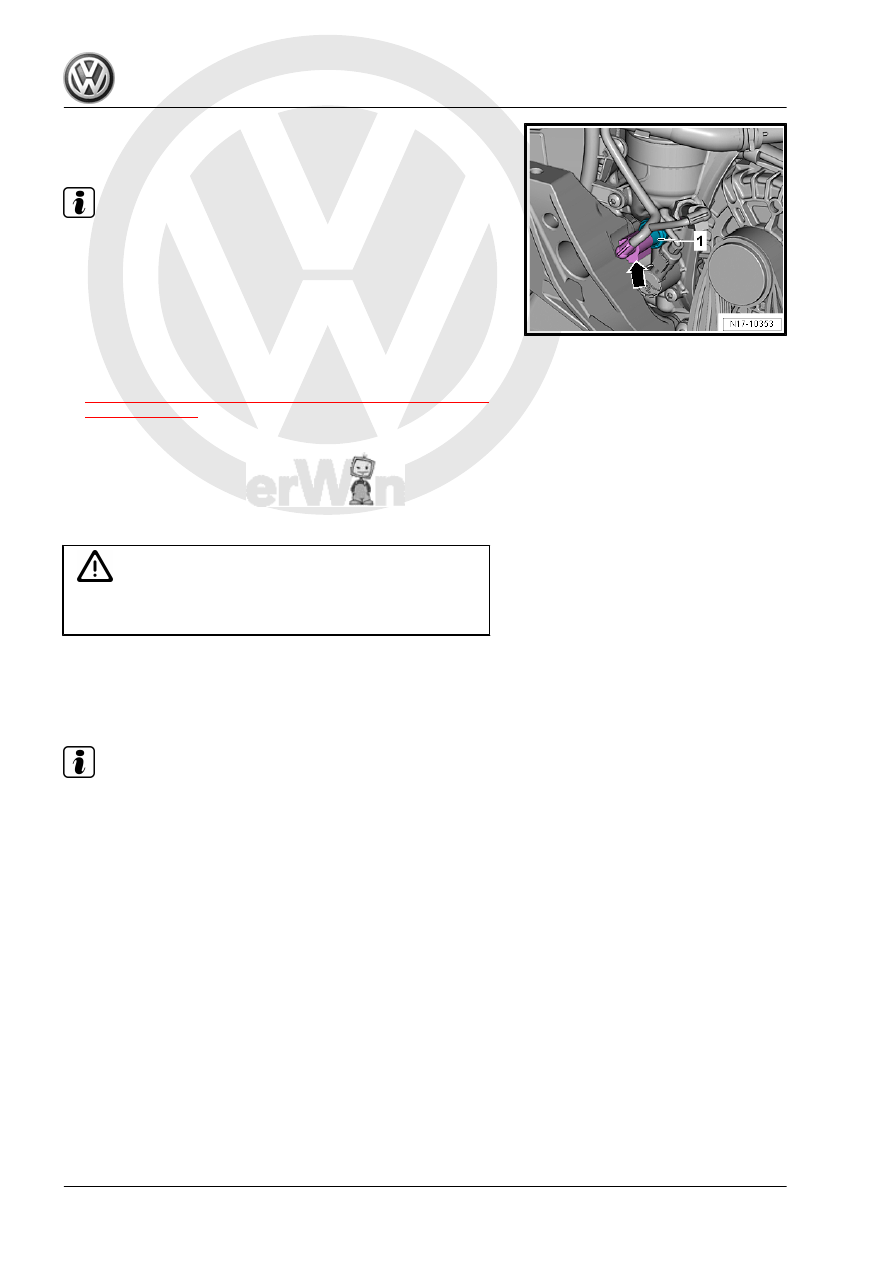

– Remove the Oil Pressure Switch -1-.

Installing

Note

To prevent oil loss, insert the Oil Pressure Switch - F1- in the

opening immediately.

Install in reverse order of removal. Note the following:

– Check the oil level. Refer to ⇒ Maintenance ; Booklet 36.1 ;

Procedure Descriptions; Engine Oil Level, Checking .

Tightening Specifications

♦ Refer to

⇒ “4.2 Overview - Oil Pressure Switch/Oil Pressure Regulator

.

4.4

Reduced Oil Pressure Switch - F378- ,

Removing and Installing

Special tools and workshop equipment required

♦ Socket and Jointed Extension - 24mm - T40175-

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Seal - Reduced Oil Pressure Switch

Removing

Note

♦

Place a cloth under the accessory assembly bracket to collect

leaking engine oil.

♦

Replace the seal after each time the oil pressure switch is

loosened.

– Disconnect the electrical connector -arrow- on the Reduced

Oil Pressure Switch - F378- .