Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 692

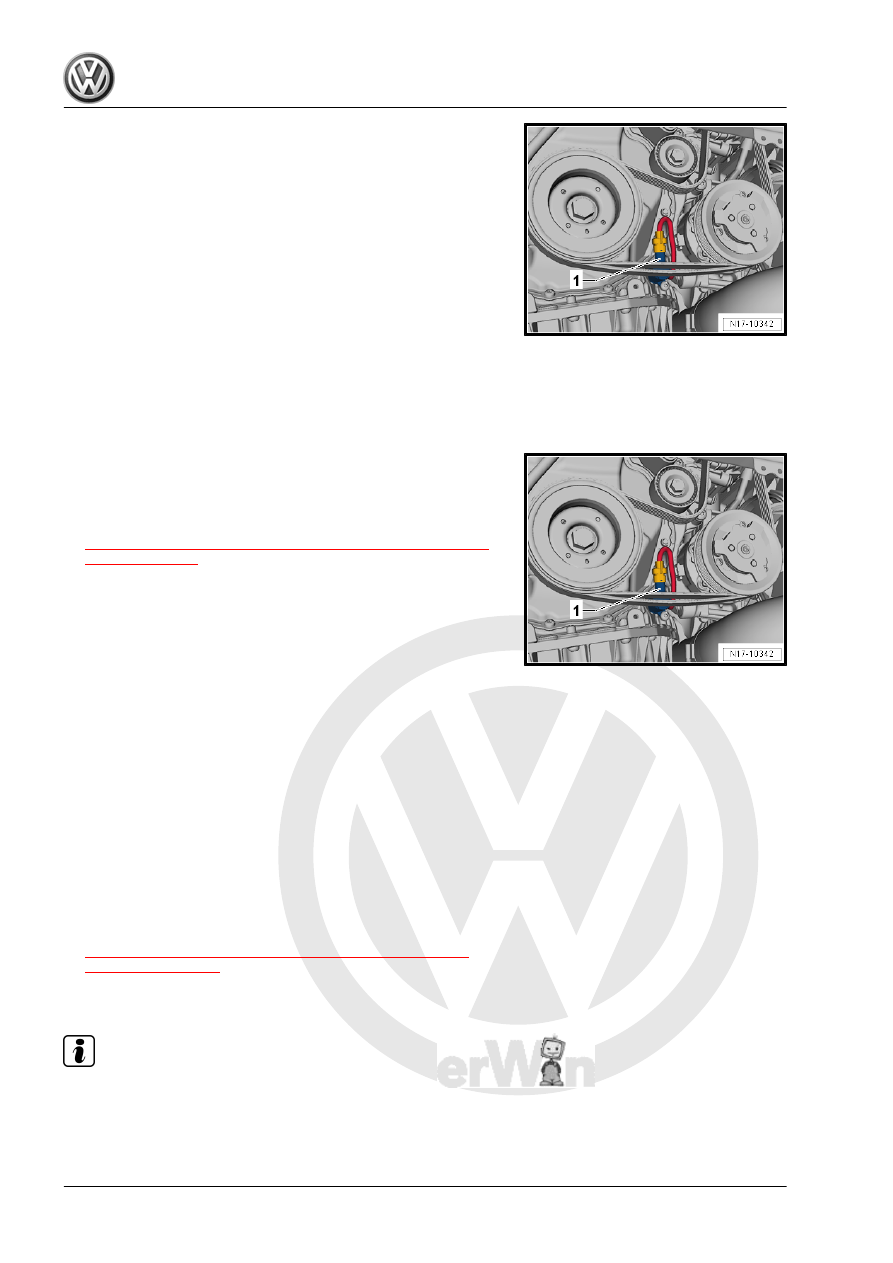

– Remove the connector -1- from the Oil Pressure Regulation

Valve - N428- . Unclip the cable and route downward so that

is not in the belt drive unit. With the connector removed the oil

pump only pumps in the higher pressure stage.

– Start the engine and check the oil pressure of the specified

RPMs.

• Oil pressure at idle: 0.85 to 4.0 bar (12.3 to 43 psi)

• Oil pressure at 2,000 RPM: 2.0 to 2.4 bar (29 to 34.8 psi)

• Oil pressure at 3,700 RPM: 3 to 4 bar (43 to 58 psi)

Assembling

– Install the oil pressure switch.

– Connect the connector -1- to the Oil Pressure Regulation

Valve - N428- . Carefully route the cable.

– Install the noise insulation. Refer to ⇒ Body Exterior; Rep. Gr.

66 ; Noise Insulation; Overview - Noise Insulation .

– Check the engine control module Diagnostic Trouble Code

(DTC) memory and erase any entries.

Tightening Specifications

♦ Refer to

⇒ “4.2 Overview - Oil Pressure Switch/Oil Pressure Regulator

.

4.6.2

Piston Spray Nozzles Oil Pressure,

Checking

Special tools and workshop equipment required

♦ Oil Pressure Gauge Kit - VAG1342-

♦ Socket and Jointed Extension - 24mm - T40175-

Test Prerequisites

• Oil level OK

• The engine oil temperature at least 80 °C (176 °F) (the coolant

fan must start up once).

Test Sequence

– Remove the Oil Pressure Switch, Level 3 - F447- . Refer to

⇒ “4.5 Oil Pressure Switch, Level 3 F447 , Removing and

.

– Install the Oil Pressure Gauge Kit - VAG1342- in place of the

oil pressure switch.

Note

Risk of damaging the oil pressure tester. The hose from the oil

pressure tester must not come in contact with the coolant pump

toothed belt sprocket.