Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 666

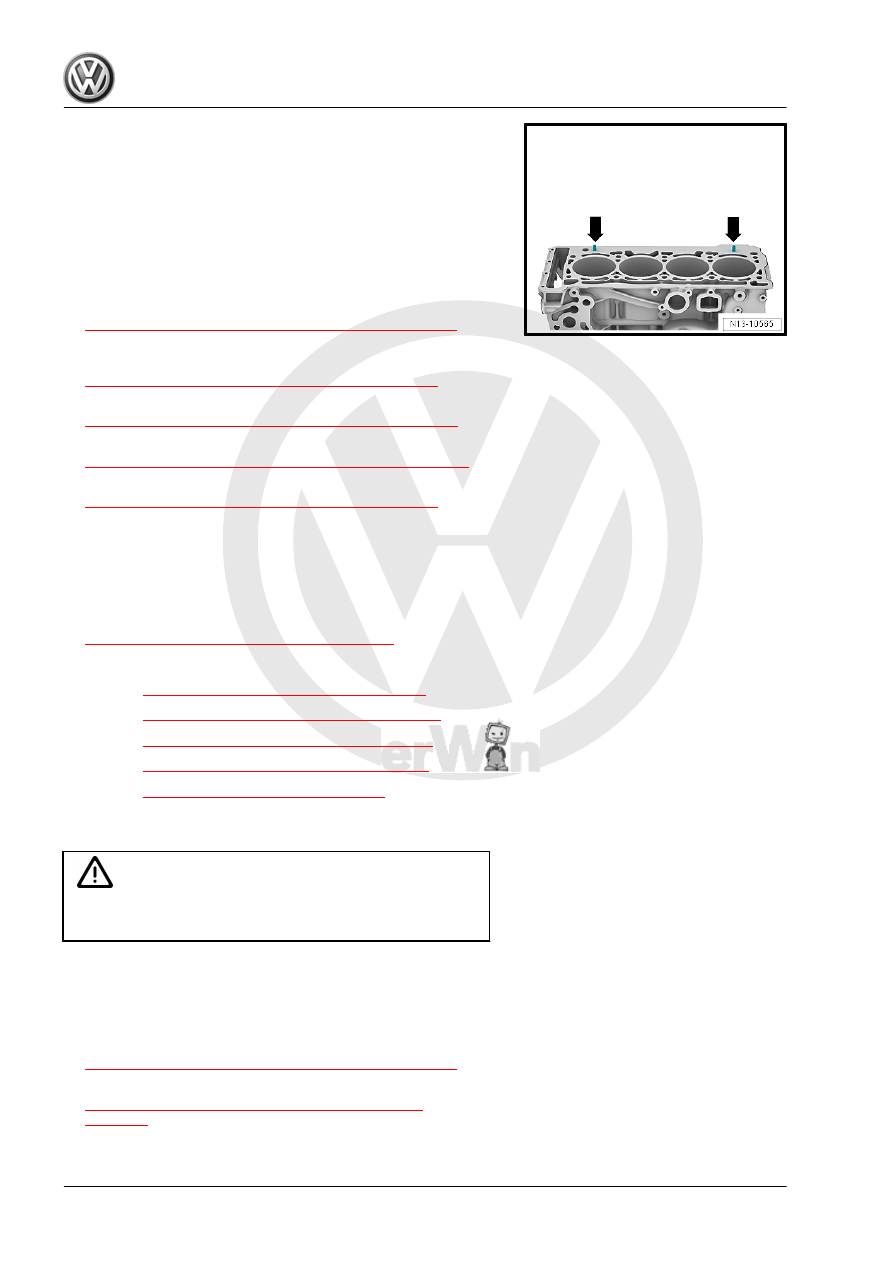

♦ Pay attention to centering pins in cylinder block -arrows-.

♦ Cylinder head gasket installed position: the part number must

be readable from the intake side.

– If the crankshaft was turned in the meanwhile: bring the piston

for cylinder 1 to Top Dead Center (TDC) and then turn the

crankshaft back just a little. Take care not to damage the timing

chain in the process.

– Set cylinder head in place.

– Install and tighten the cylinder head bolt. Tightening se‐

quence. Refer to

⇒ Fig. ““Cylinder Head Tightening Sequence”“ , page 92

– Install the camshaft but the camshaft timing chain is not in‐

stalled yet. Refer to

⇒ “4.2 Camshaft, Removing and Installing”, page 136

.

– Support the engine in its installed position again. Refer to

⇒ “2.5 Engine, Supporting in Installed Position”, page 33

.

– Remove the engine mount and the engine support. Refer to

⇒ “1.6 Engine Support, Removing and Installing”, page 55

.

– Now install the camshaft timing chain. Refer to

⇒ “4.2 Camshaft, Removing and Installing”, page 136

.

Further assembly is performed in the reverse order of removal,

thereby observing the following:

– Replace the engine oil. Refer to ⇒ Maintenance ; Booklet

36.1 ; Procedure Descriptions; Engine Oil, Draining, Replacing

Oil Filter, and Filling .

– Fill with new coolant. Refer to

⇒ “1.3 Coolant, Draining and Filling”, page 217

.

Tightening Specifications

♦ Refer to

⇒ “1.1 Overview - Cylinder Head”, page 90

♦ Refer to

⇒ “4.1 Overview - Intake Manifold”, page 296

♦ Refer to

⇒ “3.1 Overview - Coolant Pipes”, page 241

♦ Refer to

⇒ “1.1 Overview - Turbocharger”, page 256

.

♦ Refer to

⇒ “1.1 Overview - Muffler”, page 338

.

1.4

Vacuum Pump, Removing and Installing

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Seal - Vacuum Pump

Removing

– Remove the engine cover. Refer to

⇒ “3.1 Engine Cover, Removing and Installing”, page 38

– Remove the air filter housing. Refer to