Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 662

– Using a Cylinder Dial Bore Gauge - VAS6078- measure in a

diagonal sequence at three positions transversely -A- and lon‐

gitudinally -B-.

♦ Deviation from specified size: maximum 0.08 mm

Basic Dimension

Cylinder Bore Diame‐

ter

in mm

82.51

5.4

New Connecting Rod, Separating

New connecting rods might not be separated at the location

where they should be. If the connecting rod bearing cap cannot

be removed by hand, proceed as follows:

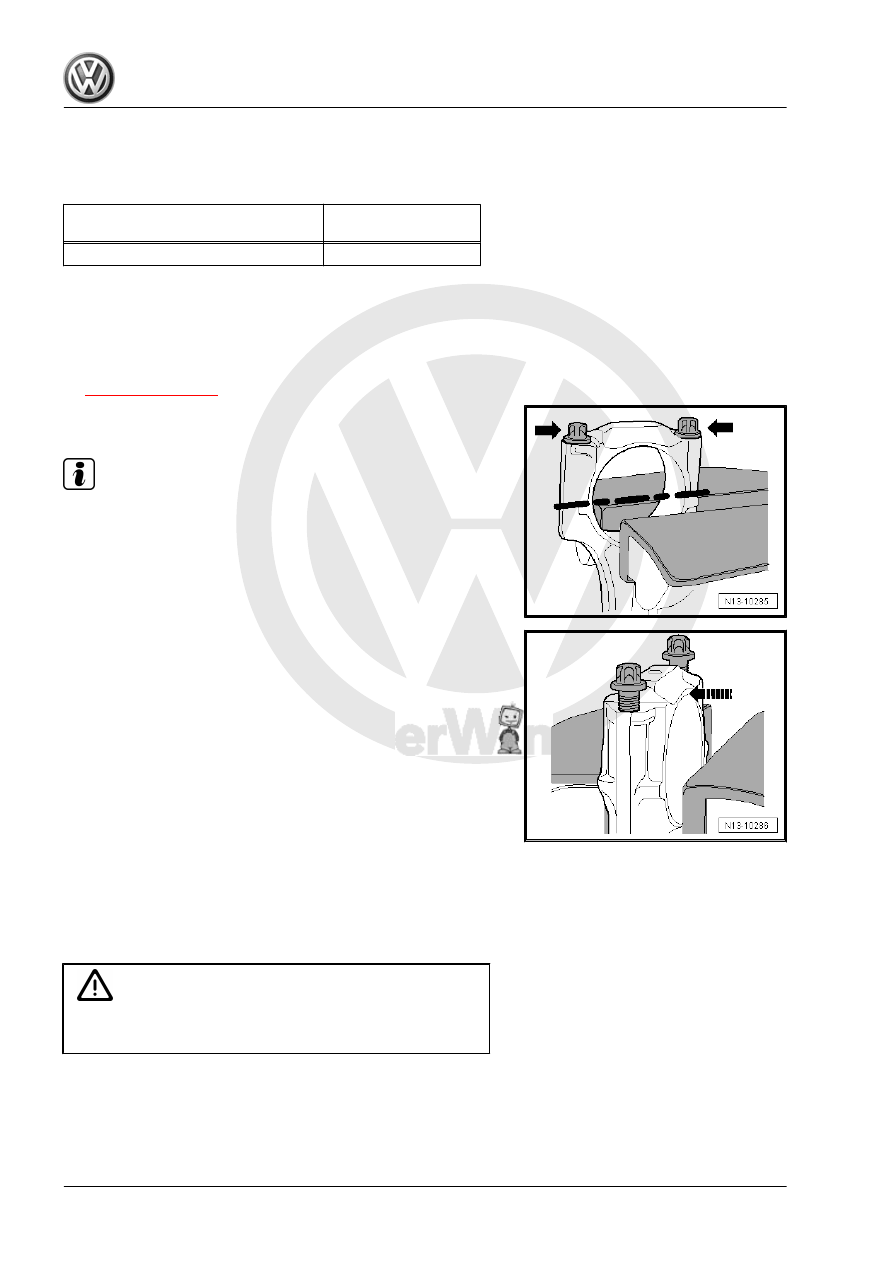

– Label which cylinder goes with the connecting rod -item 11-

.

– Lightly clamp the connecting rod in a vise equipped with alu‐

minum protective pads.

Note

♦

Clamp the connecting rod lightly to prevent damaging it.

♦

Clamp the connecting rod below the dotted line.

– Loosen the bolts -arrows- approximately 5 turns.

– Carefully tap against the connecting rod bearing cap in direc‐

tion of -arrow- with a plastic hammer until the cap is loose.

5.5

Connecting Rods, Checking Radial

Clearance

Special tools and workshop equipment required

♦ Plastigage

®

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Bolts - Connecting Rod

Procedure

– Remove the connecting rod bearing cap.