Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 660

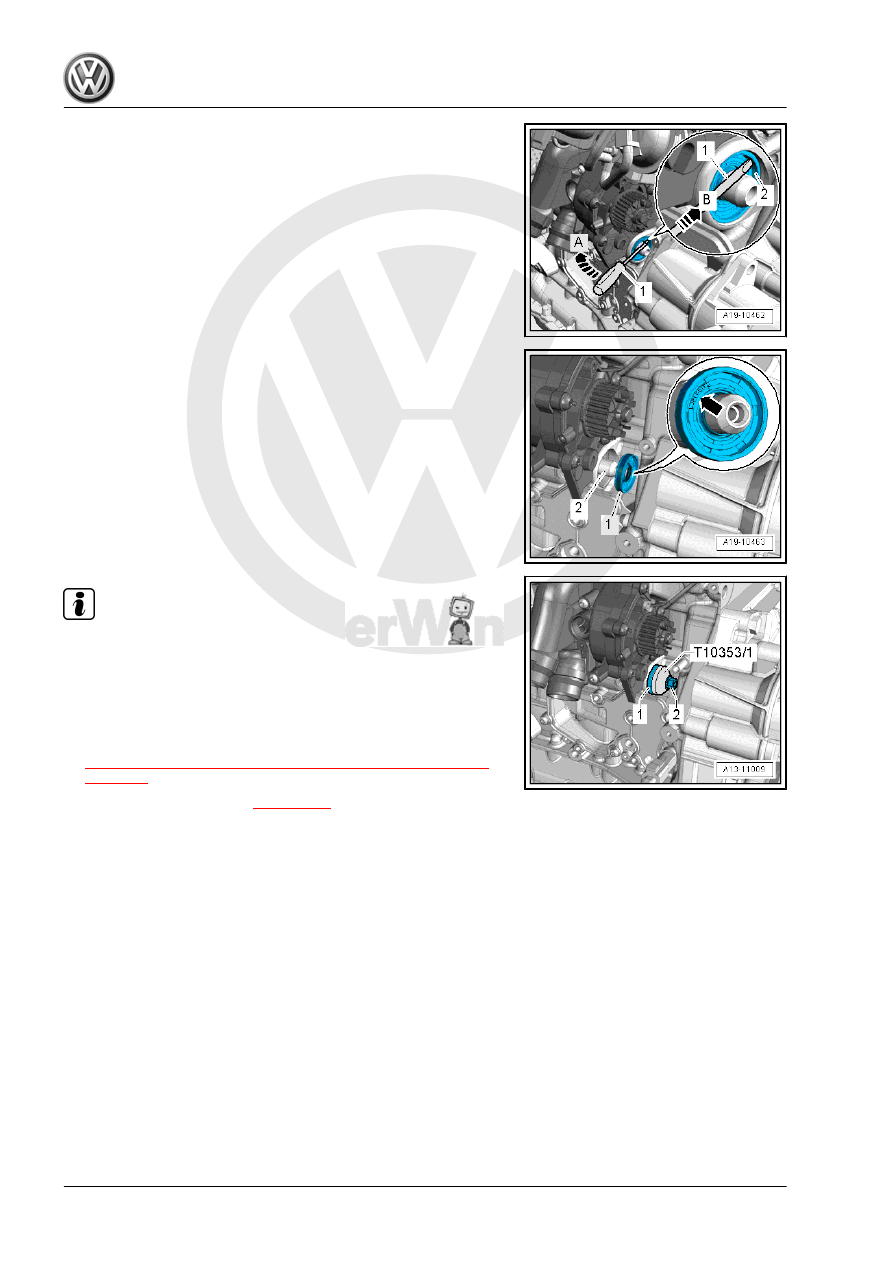

– Pry out the seal in direction of -arrow A-.

– Clean the running and sealing surface.

– Coat the sealing surface of the balance shaft -2- with trans‐

mission oil.

– Push the seal -1- onto the balance shaft.

• “Luftseite” or (“Outside”) -arrow- must be readable from the

outside.

Note

The drive wheel bolt -2- has left-hand thread.

– Mount the Seal Installer, Intermediate Shaft - T10353/1- on the

shaft seal -1- and then tighten it all the way into the cylinder

block with the bolt -2-. Be careful not to tilt the shaft seal when

doing this.

– Install the toothed belt on the coolant pump. Refer to