Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 645

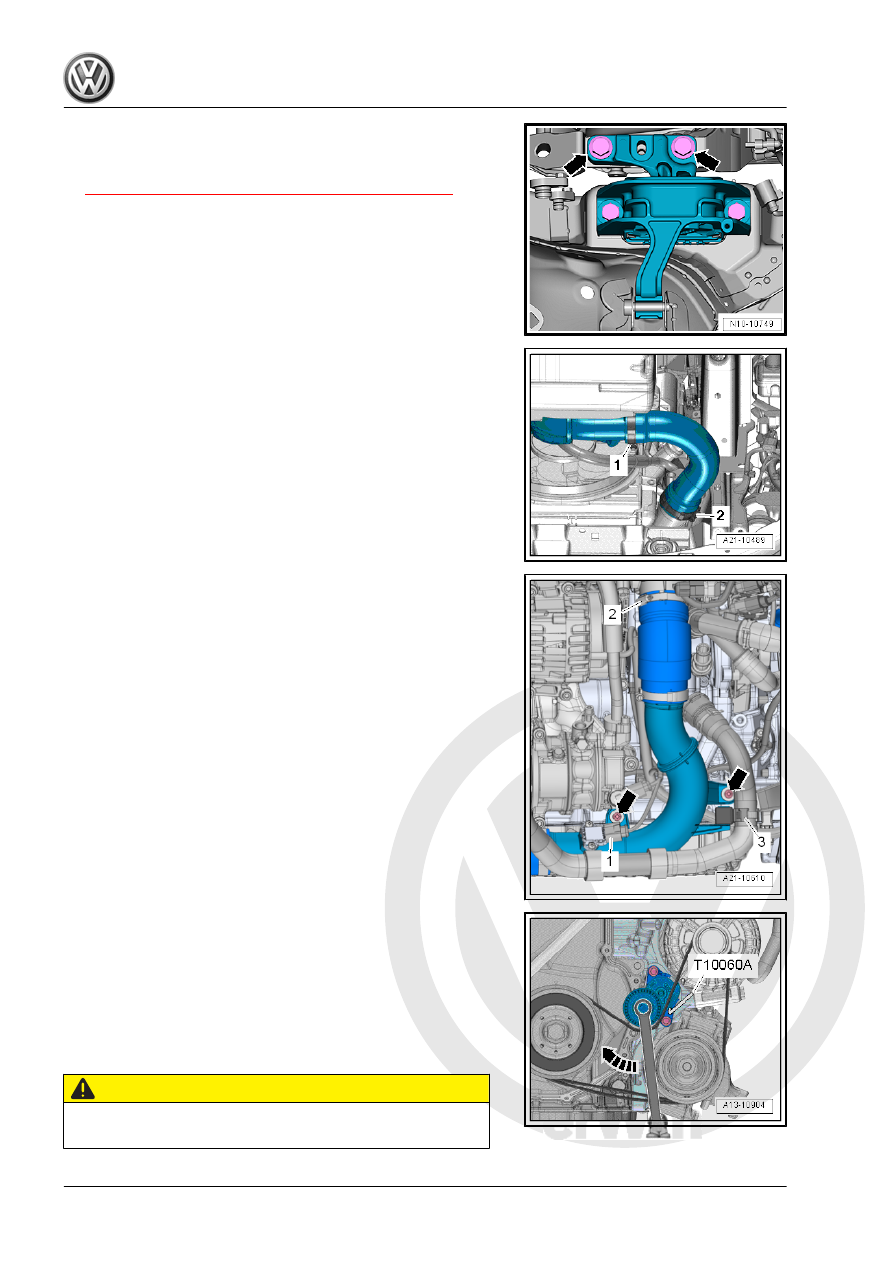

– Remove the bolts -arrows- for the engine mount (about two

turns).

– Remove the fan shroud. Refer to

⇒ “4.5 Fan Shroud, Removing and Installing”, page 249

– Open the clamp -1 and 2- and remove the air duct hose.

– Seal the open lines and connections with clean plugs from the

Engine Bung Set - VAS6122- .

– Free up the coolant hose -3-.

– Remove the bolts -arrows-.

– Loosen the hose clamp -2-.

– Disconnect the connector -1- on the Charge Air Pressure Sen‐

sor - G31- .

– Remove the right air guide pipe.

– Before removing the ribbed belt, mark the running direction

with chalk or a felt-tip pen for reinstallation.

– Pivot the tensioner clockwise in direction of -arrow- to release

the tension on the ribbed belt.

– Remove the ribbed belt from the A/C compressor ribbed belt

pulley and release the tension on the tensioning device. If

necessary, remove the Locking Pin - T10060A- .

CAUTION

Danger of frostbite from refrigerant.

– Do not open the A/C system refrigerant circuit.