Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 634

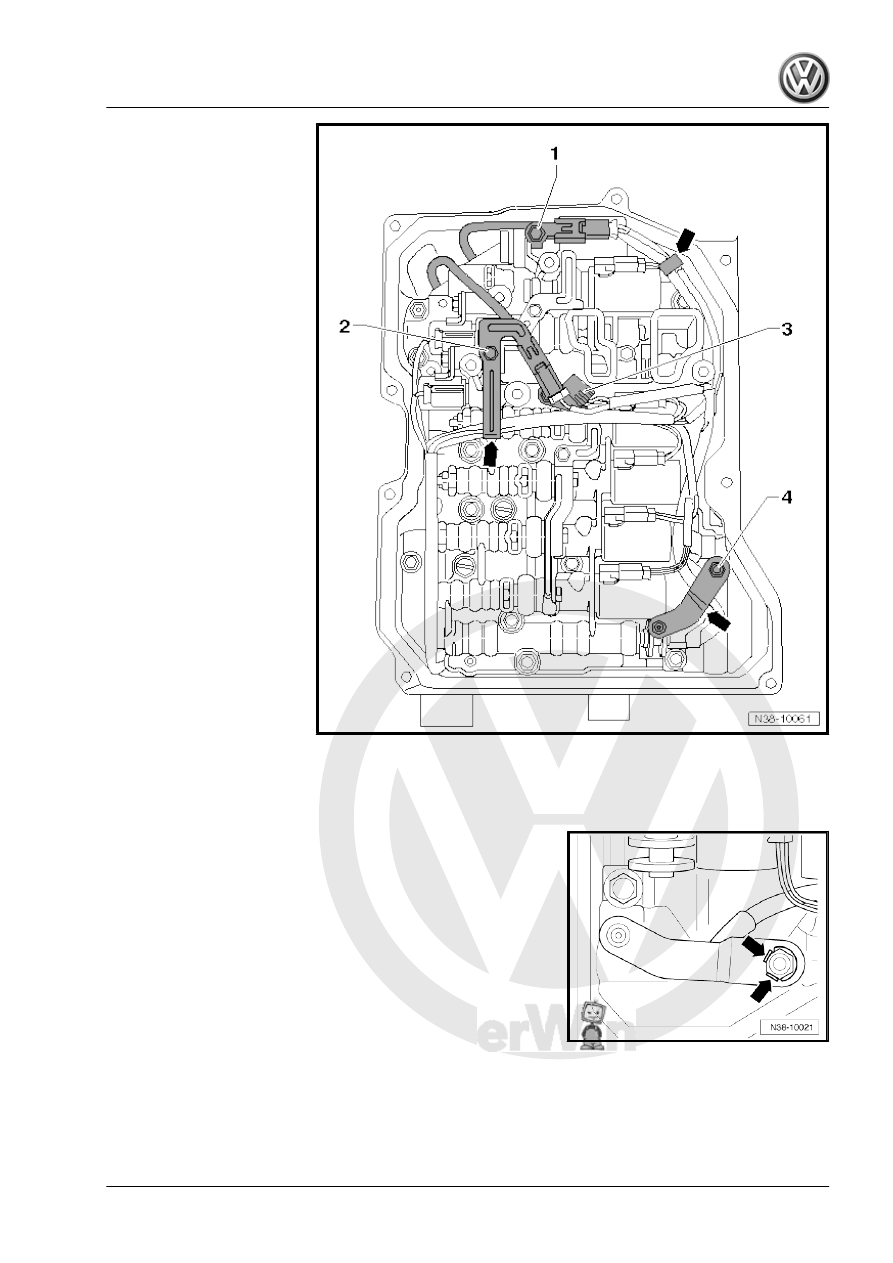

– Remove the Transmission Fluid Temperature Sensor - G93-

-3- from the valve body.

– Disengage the wiring harnesses from the brackets -arrows-.

– If equipped, bend back the locking plate on the selector lever

-arrows-.