Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 635

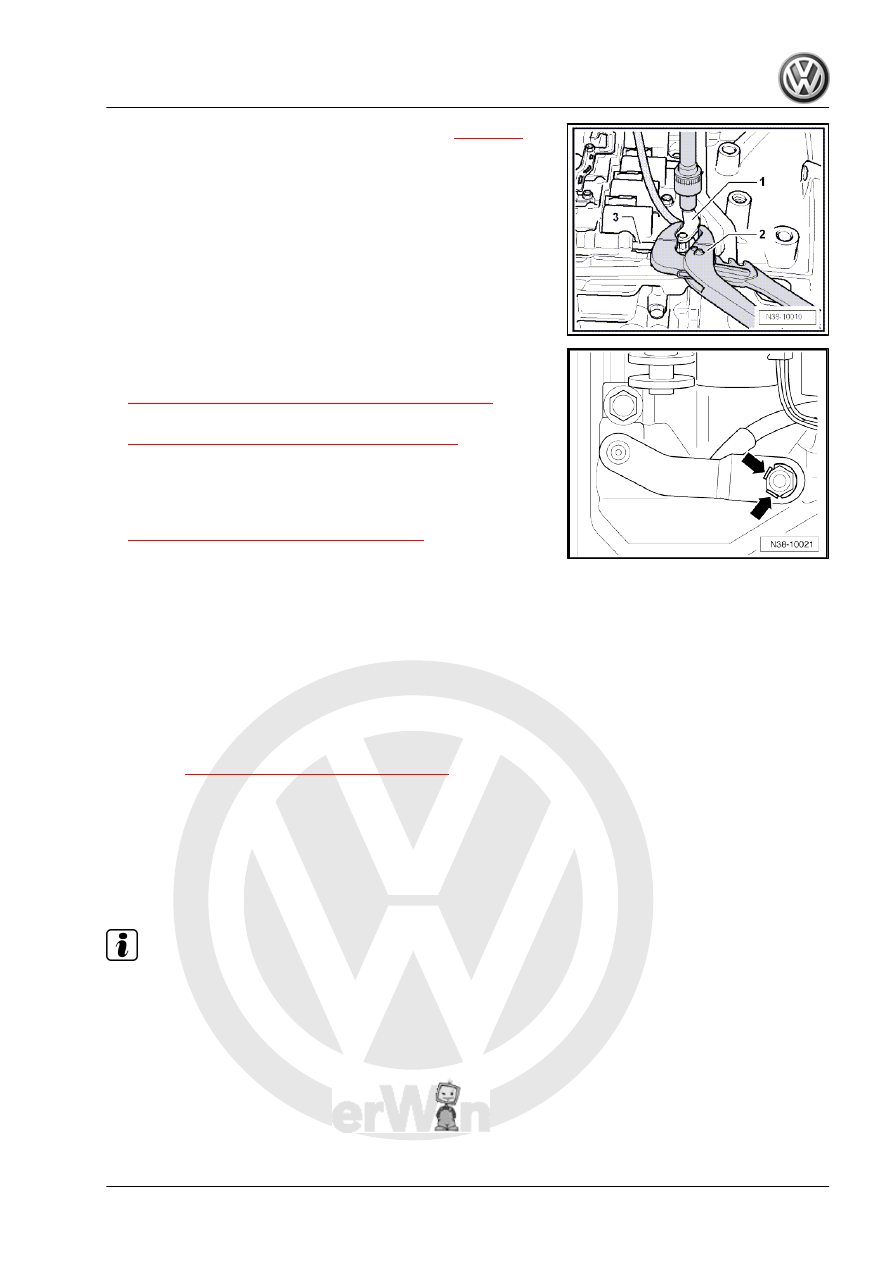

– Tighten the nut on the selector lever -1-. Refer to

.

– When doing this, hold the selector lever -1- secure with pliers

-2- so that it does not turn when removing the Multifunction

Transmission Range Switch - F125- .

– Make sure the slide -3- on the valve body in which the shift

lever engages is not damaged.

– Bend up the locking plate at the nuts -arrows-, if equipped.

– Install the ATF strainer. Refer to

⇒ “1.2 ATF Strainer, Removing and Installing”, page 86

.

– Install the ATF pan. Refer to

⇒ “1.1 Oil Pan, Removing and Installing”, page 84

– Connect the battery Ground (GND) cable. Refer to ⇒ Electrical

Equipment; Rep. Gr. 27 ; Battery; Battery, Disconnecting and

Connecting .

– Fill the ATF and check the level. Refer to

⇒ “7 Automatic Transmission Fluid”, page 73

.

– Connect, for example the Vehicle Diagnostic Tester and select

“function/component selection”.

– Press “drive (Repair Groups 01; 10 through 26 and

28 through 39)”.

– After that “6-speed automatic transmission 09G”.

– Press “01 - OBD”.

– Press “Functions”.

– Press “basic setting”.

Tightening Specifications

♦ Refer to

⇒ “2.1 Overview - Valve Body”, page 87

2.3

Wire Routing, Connectors and Bracket

on Valve Body

In this chapter the information regarding working on the solenoid

valves is shown in illustrations.

Wiring Routing and Connectors

Note

Mark the solenoid valve and/or sensor and its connector before disconnecting them.