Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 632

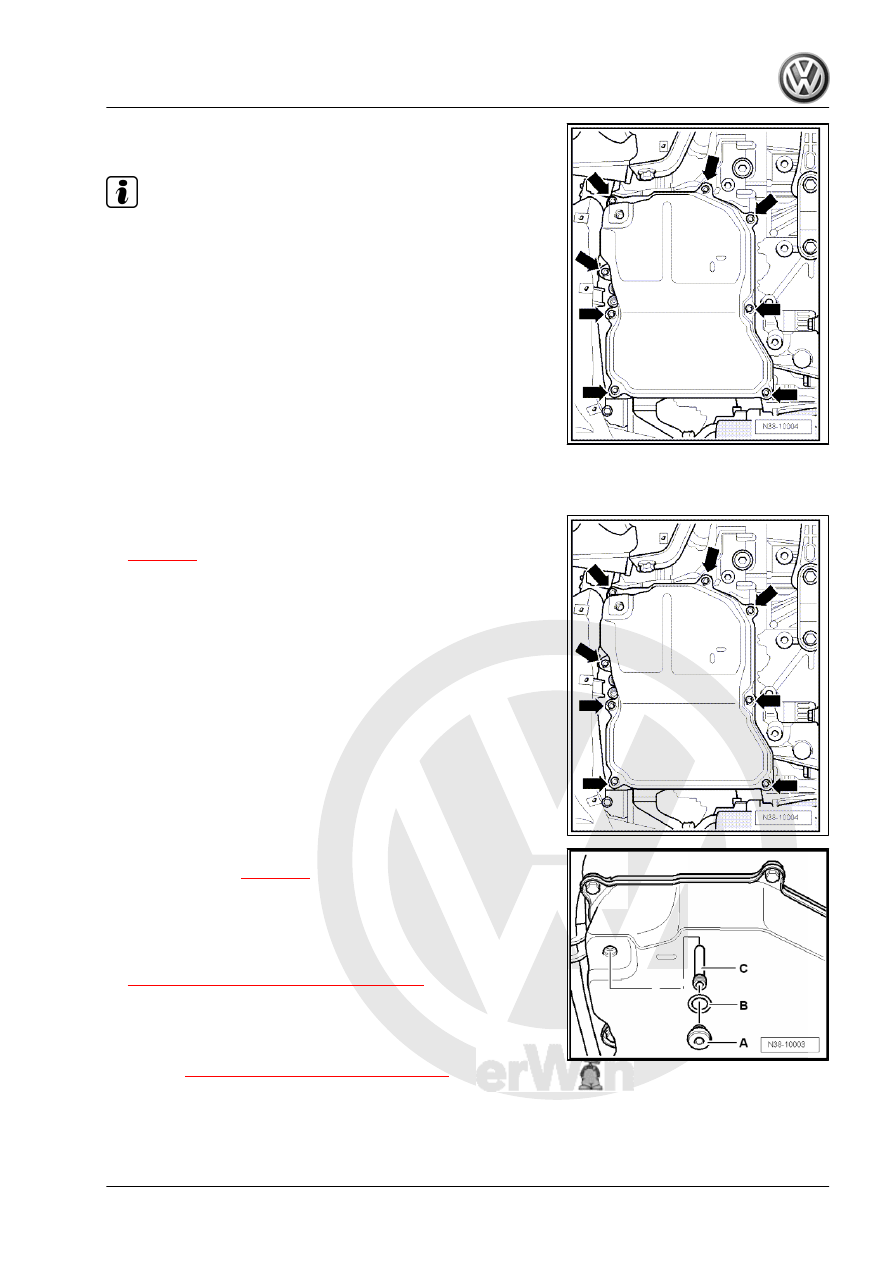

– Loosen and tighten the bolts on the ATF pan -arrows- diago‐

nally.

Note

Some residual ATF will remain in the ATF pan.

– Remove the ATF pan and gasket.

Installing

Install in reverse order of removal. Note the following:

– Clean the two magnets in the ATF pan depressions. Make

sure the magnets touch the ATF pan completely.

– Check the seal for damage and make sure all of the spacers

(quantity: 8) are present.

Otherwise, replace the seal.

– Install the ATF pan and seal; when doing this be sure not to

pinch any lines.

– Make sure the ATF pan seal fits correctly.

– Tighten the ATF pan bolts -arrows- diagonally and in several

steps. For the correct tightening specification. Refer to

– Install the overflow pipe -C-. For the correct tightening speci‐

fication. Refer to

.

– Replace the gasket -B- for the ATF check plug -A-.

– Install the ATF check plug -A- and new gasket -B- hand-tight

only.

– Fill the ATF and check the level. Refer to

⇒ “7 Automatic Transmission Fluid”, page 73

.

– Install the noise insulation. Refer to ⇒ Body Exterior; Rep. Gr.

66 ; Noise Insulation; Overview - Noise Insulation .

Tightening Specifications

♦ Refer to