Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 109

DTC /

Descrip‐

tion

Monitor

Strategy

Descrip‐

tion

Malfunction Crite‐

ria and Threshold

Value

Secondary Parame‐

ters with Enable

Conditions

Monitoring

Time

Length

MIL Il‐

lum.

Component Diag‐

nostic Procedure

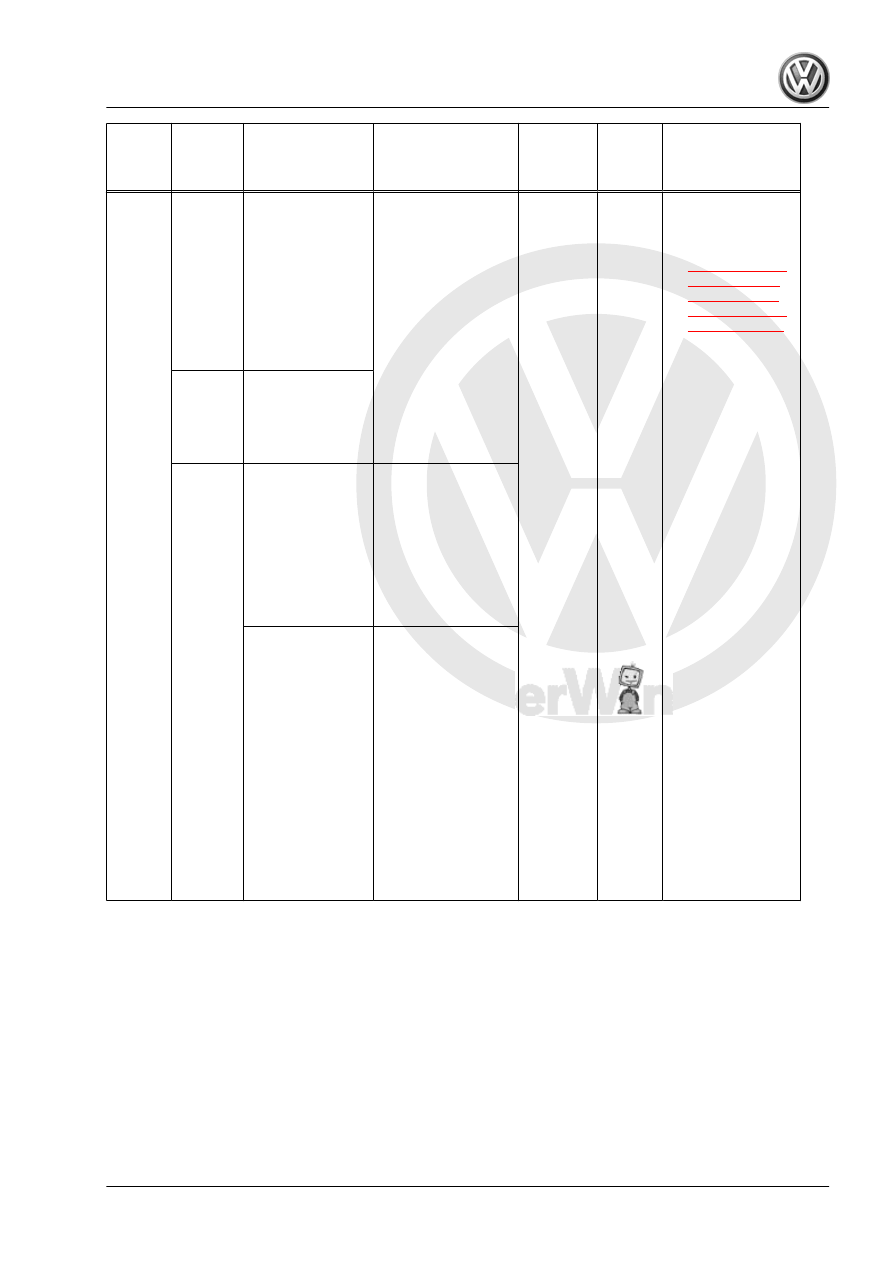

P0354

Ignition

Coil "D"

Primary

Control

Circuit/

Open

Ignition

Coils

Open Cir‐

cuit

• Output voltage

in OFF state,

lower range >=

1.92 – 2.21 V

• Output voltage

in OFF state,

upper range

(hardware val‐

ues) <= 2.85 –

3.25 V

• Engine speed >

512 RPM

• ECT @ cylinder

head > -30° C

• Engine stop not

active

• 1.0 s

• Contin‐

uous

• 2

DCY

– Check the Igni‐

tion Coils with

Power Output

Stage . Refer to

Ignition

Coils

Short To

Ground

• Output current

in ON state

(hardware val‐

ues) > 50 – 100

mA

Ignition

Coils

Short To

Battery

Plus

• Diagnosis by

inactive low

side: switch in

ATIC:

• output voltage

in OFF state

(hardware val‐

ues) > 4.95 –

5.285 V

• Engine speed >

512 RPM

• Engine stop not

active

• Actuator com‐

manded off

• Diagnosis by

inactive low

side: switch in

ATIC:

• Output temper‐

ature from AT‐

IC in ON state >

160.0 – 200.0°

C

• Or

• Output current

in ON state

(hardware val‐

ues) > 100.0 –

180.0 mA

• Engine speed >

512 RPM

• Engine stop not

active

• Actuator com‐

manded on

GTI 2014 ➤

Generic Scan Tool - Edition 04.2015

3. Diagnosis and Testing

109