Suzuki Grand Vitara JB627. Manual - part 128

2C-4 Rear Suspension:

Reference Information

Side slip

When checked with side slip tester, side slip should satisfy following specification.

Side slip specification

IN 7.5 mm/m (IN 0.2953 in/3.3 ft)

If side slip is greatly different, toe and/or camber may be not correct.

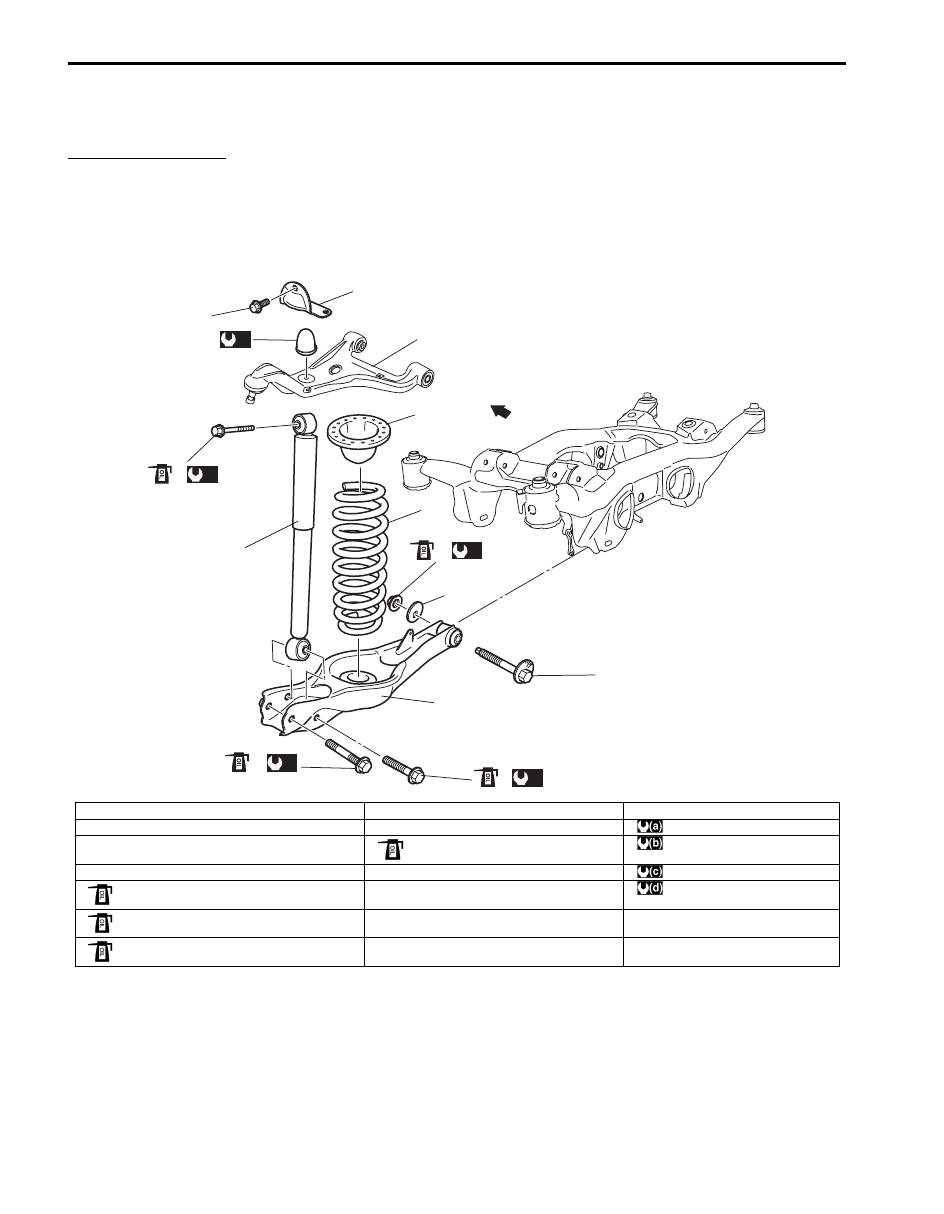

Rear Shock Absorber and Rear Coil Spring Components

S6JB0B2306002

13

11

3

2

9

8

4

1

(b)

(b)

10

7

F

14

(a)

5

(c)

6

12

(d)

I6JB0B230002-01

1. Rear shock absorber

8. Lower arm inner bolt

F: Vehicle forward

2. Rear coil spring

9. Lower arm washer

: 60 N

⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Coil spring rubber seat

10. Lower arm mount nut

: If reuse nut, apply engine oil to thread.

: 135 N

⋅m (13.5 kgf-m, 98.0 lb-ft)

4. Lower arm

11. Upper arm

: 90 N

⋅m (9.0 kgf-m, 65.0 lb-ft)

5. Shock absorber upper bolt

: If reuse bolt, apply engine oil to thread.

12. Bump stopper

: 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

6. Shock absorber lower bolt

: If reuse bolt, apply engine oil to thread.

13. Bump stopper upper seat

7. Lower arm outer bolt

: If reuse bolt, apply engine oil to thread.

14. Bump stopper upper seat bolt