Suzuki Grand Vitara JB627. Manual - part 129

2C-8 Rear Suspension:

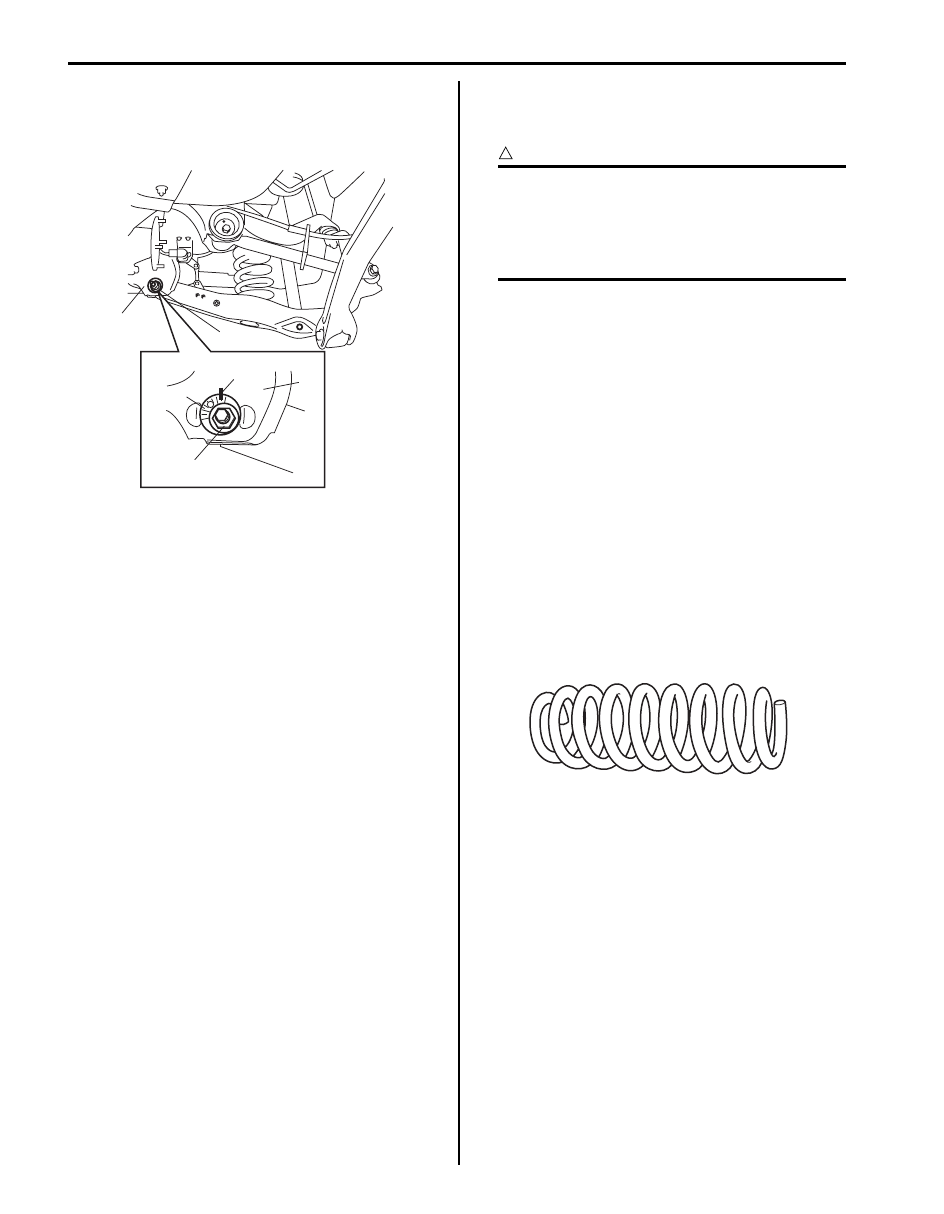

6) With marks (1) on lower arm washer (2) and rear

suspension frame (3) marked before remove aligned

to each other, tighten lower arm mount nut (4)

temporarily by hand.

7) Install rear shock absorber referring to “Rear Shock

Absorber Removal and Installation”.

8) Connect rear height sensor link (if equipped) to lower

arm for left side referring to “Height Sensor Removal

and Installation (If Equipped) in Section 9B”.

9) Install wheel with nuts and lower vehicle.

10) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

11) Tighten lower arm outer bolt and lower arm mount

nut, shock absorber bolts to specified torque with

vehicle weight on suspension.

CAUTION

!

• It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

• Tighten Lower arm washer with match

marks aligned.

Tightening torque

Lower arm outer bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

Lower arm mount nut: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

Shock absorber upper bolt: 60 N·m (6.0 kgf-m,

43.5 lb-ft)

Shock absorber lower bolt: 90 N·m (9.0 kgf-m,

65.0 lb-ft)

12) Check rear toe and camber adjust it as necessary.

For check and adjustment procedures, refer to “Rear

Wheel Alignment Inspection and Adjustment”.

13) Adjust headlight auto leveling system, refer to

“Initialization of Auto Leveling Headlight System in

Section 9B”.

Rear Coil Spring Check

S6JB0B2306006

• Inspect for cracks, deformation or damage. If any,

replace defective part.

1

2

3

3

4

4

I5JB0A230010-01

I5JB0A230016-01