Suzuki Grand Vitara JB627. Manual - part 93

1D-53 Engine Mechanical:

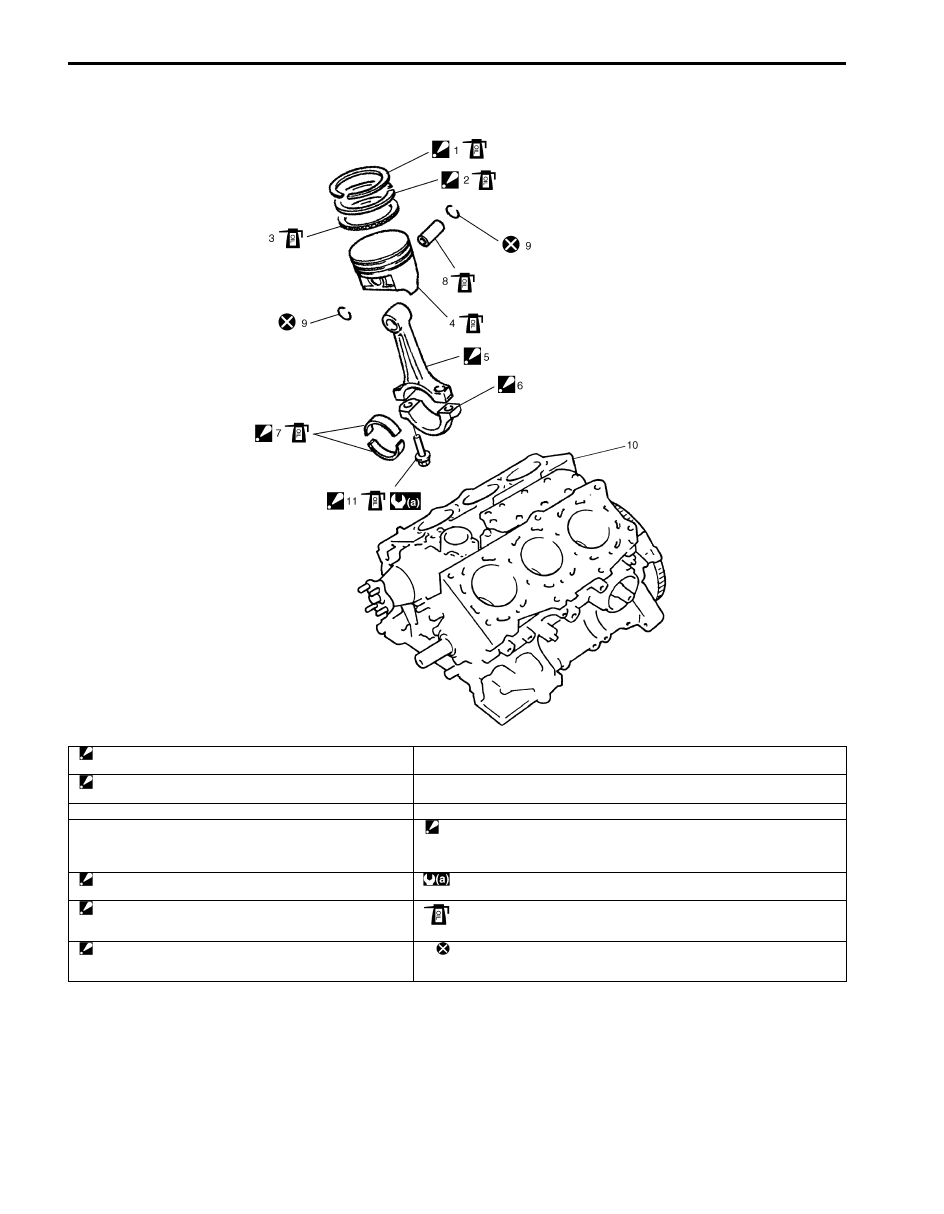

Pistons, Piston Rings, Connecting Rods and Cylinders Components

S6JB0B1406037

I6JB01140090-01

1. Top ring

: “RN” mark provided on piston ring comes to facing up.

8. Piston pin

2. 2nd ring

: “R” mark provided on piston ring comes to facing up.

9. Piston pin circlip

3. Oil ring

10. Cylinder block

4. Piston

11. Connecting rod bolt

: Check connecting rod bolt referring to “Connecting Rod Bolt Deformation

(Plastic Deformation Tightening Bolt)” under “Crank Pins and Connecting Rod

Bearings Inspection” if it is reused.

5. Connecting rod

: Do not apply engine oil to inner surface of big end.

: Tighten 15 N

⋅m (1.5 kgf-m, 11.0 lb-ft), 45° and 45° by the specified procedure.

6. Connecting rod bearing cap

: Point arrow mark on cap to crankshaft pulley side. Do not

apply engine oil to inner surface of bearing cap.

: Apply engine oil to sliding surface of each part.

7. Connecting rod bearing

: Do not apply engine oil between connecting rod big end and

bearing, between cap and bearing.

: Do not reuse.