Suzuki Grand Vitara JB627. Manual - part 91

1D-45 Engine Mechanical:

Valves and Cylinder Heads Removal and

Installation

S6JB0B1406032

Removal

1) Remove engine assembly from vehicle referring to

“Engine Assembly Removal and Installation”.

2) Remove camshafts, tappets and shims referring to

“Camshafts, Tappets and Shims Removal and

Installation”.

3) Remove exhaust manifold referring to “Exhaust

Manifold Removal and Installation in Section 1K”.

4) Remove water outlet cap.

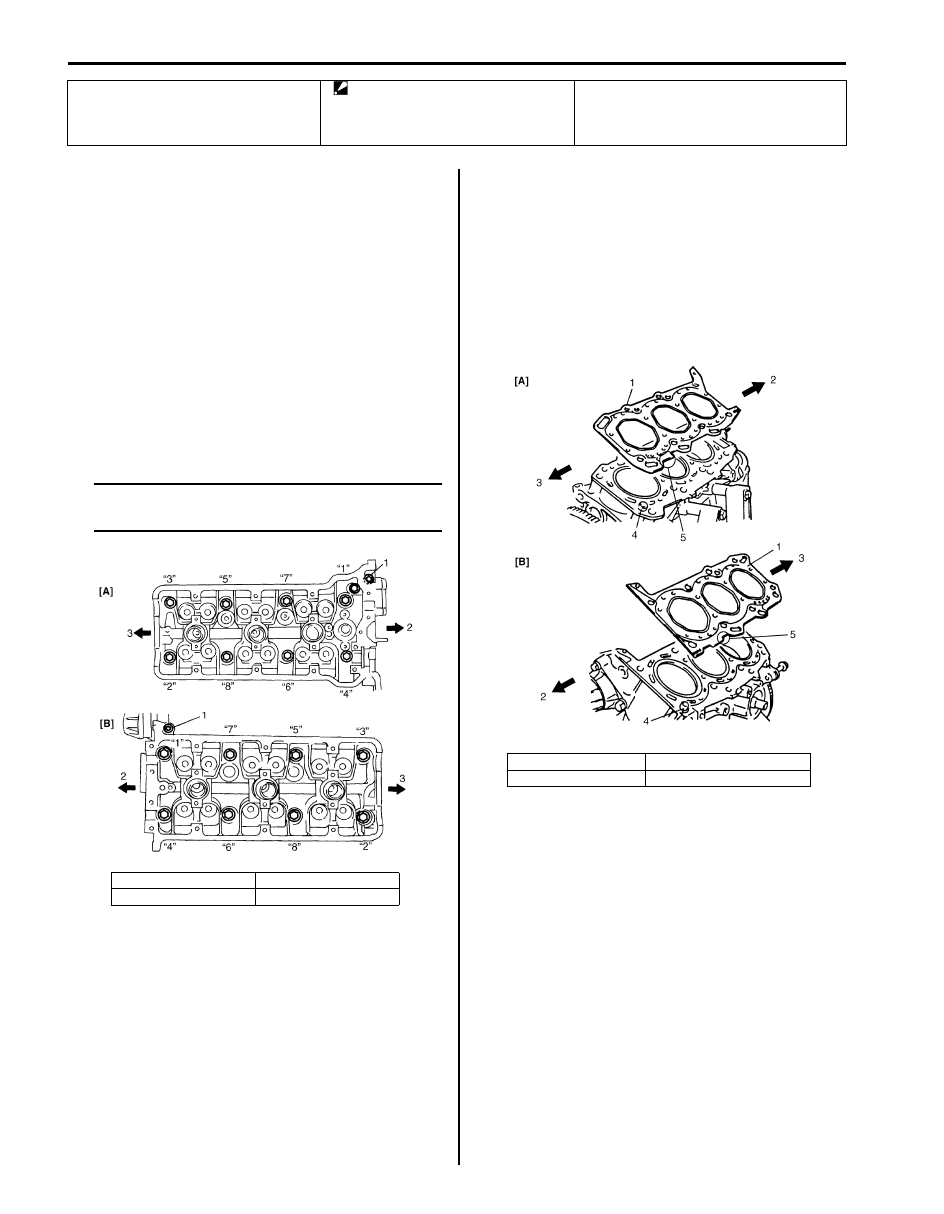

5) Loosen cylinder head bolts in such order (“1”

→ “8”)

as shown in figure and remove them.

NOTE

Be sure to remove 2 hex bolts (1) shown in

figure.

6) Remove cylinder heads.

Installation

1) Clean mating surface on cylinder head and cylinder

block. Remove oil, old gasket and dust from mating

surface.

2) Install knock pin (4) to cylinder block.

3) Install new cylinder head gasket (1) to cylinder block

as shown in figure. Carved lot number (5) on cylinder

head gasket (1) should face up (toward cylinder

head side).

7. Intake valve

14. Cylinder head bolt

: Check cylinder head bolt (M10) for

deformation referring to “Cylinder Head

Bolt” under “Valves and Valve Guides

Inspection”, if it is reused.

[A]: RH (No.2) bank

2. Timing chain side

[B]: LH (No.1) bank

3. Flywheel side

I6JB01140086-01

[A]: RH (No.2) bank

2. Crankshaft pulley side

[B]: LH (No.1) bank

3. Flywheel side

I6JB01140087-01