Subaru Legacy IV (2008 year). Manual - part 979

AC-19

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

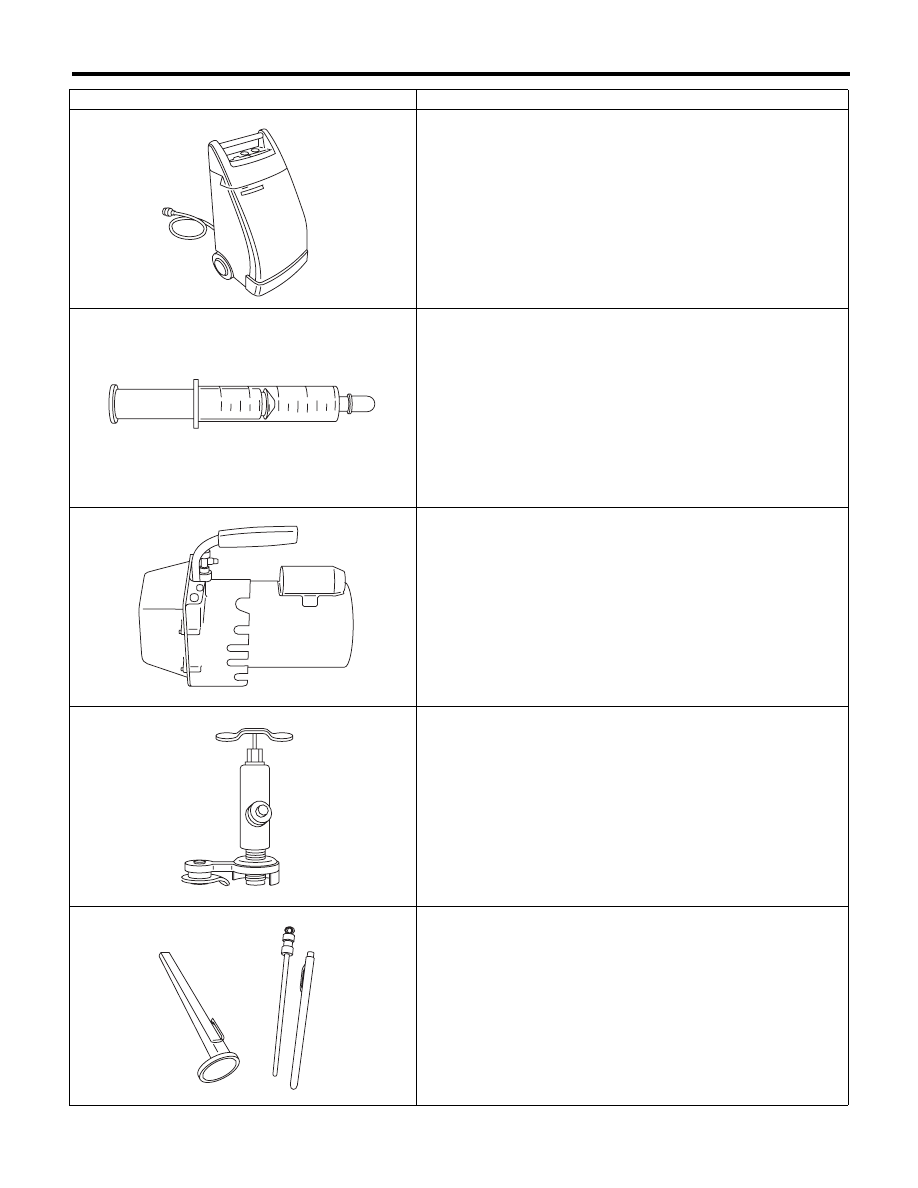

Refrigerant recovery system

A REFRIGERANT RECOVERY SYSTEM is used for the recovery and

recycling of A/C system refrigerant after contaminants and moisture

have been removed from the refrigerant.

Syringe

A graduated plastic SYRINGE will be needed to add oil into the system

again. A syringe can be available at a pharmacy or drug store.

Vacuum pump

A VACUUM PUMP is necessary (for a good working condition), and is

available either at a refrigerant supplier or an automotive equipment

supplier.

Can tap

A CAN TAP for the 397 g (14 oz.) can is available at an automotive

equipment supplier.

Thermometer

A Pocket THERMOMETER is available either at a industrial hardware

store or a refrigerant supplier.

ILLUSTRATION

Tools and Equipment

AC-00014

AC-00015

AC-00016

AC-00017

AC-00018