Subaru Legacy IV (2008 year). Manual - part 980

AC-23

Refrigerant Charging Procedure

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

4. Refrigerant Charging

Procedure

A: PROCEDURE

CAUTION:

• While working, make sure to wear protective

goggles and gloves.

• Air in the cycle can cause insufficient air con-

ditioning, and water in the cycle can cause

clogging in the cycle (icing) and rust. To re-

move this air and water content, use a vacuum

pump to perform evacuation of the system be-

fore filling with refrigerant. By making the in-

side of the cycle a vacuum, the water content

will evaporate even at atmospheric tempera-

tures, and can be removed.

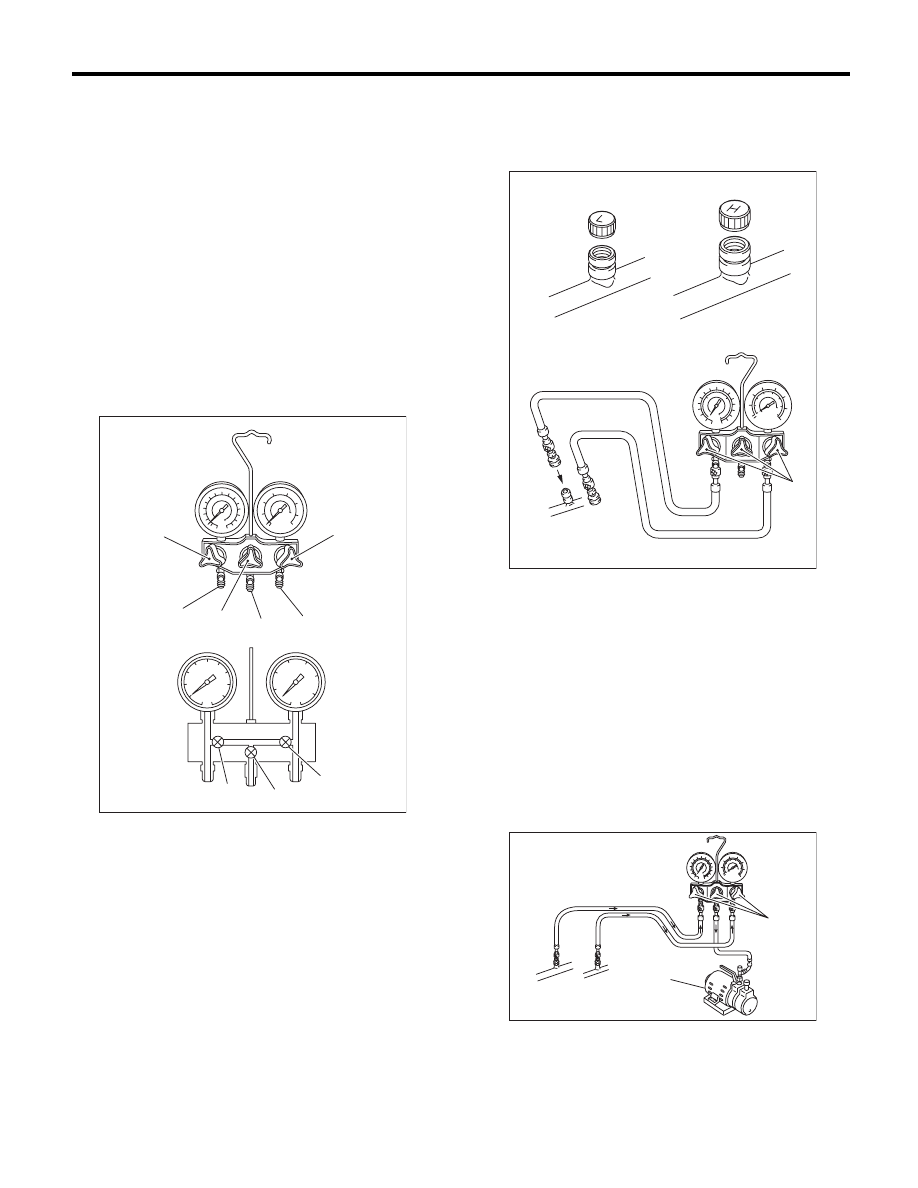

1) Close all valves of the manifold gauge.

2) Attach the low pressure side and high pressure

side hoses to the vehicle service port.

CAUTION:

Confirm that the connection is secure.

3) Connect the center manifold hose of the mani-

fold gauge to the vacuum pump.

4) Operate the vacuum pump and open the low

pressure and high pressure side valves. Next, open

the center manifold hose valve, and begin evacua-

tion.

CAUTION:

Make sure to perform evacuation using a vacu-

um pump.

L: Low pressure gauge

H: High-pressure gauge

(1) Low pressure valve

(2) Vacuum pump valve

(3) High pressure valve

(4) For low pressure

(5) For vacuum pump

(6) For high pressure

AC-00146

(2)

(4)

(5)

(6)

(3)

(3)

(2)

(1)

H

L

(1)

(1) Low-pressure side service port

(2) High-pressure side service port

(3) Close

(1) Vacuum pump

(2) Open

AC-00147

(3)

(2)

(1)

AC-00148

(1)

(2)