Subaru Legacy IV (2008 year). Manual - part 895

DS-25

Front Drive Shaft

DRIVE SHAFT SYSTEM

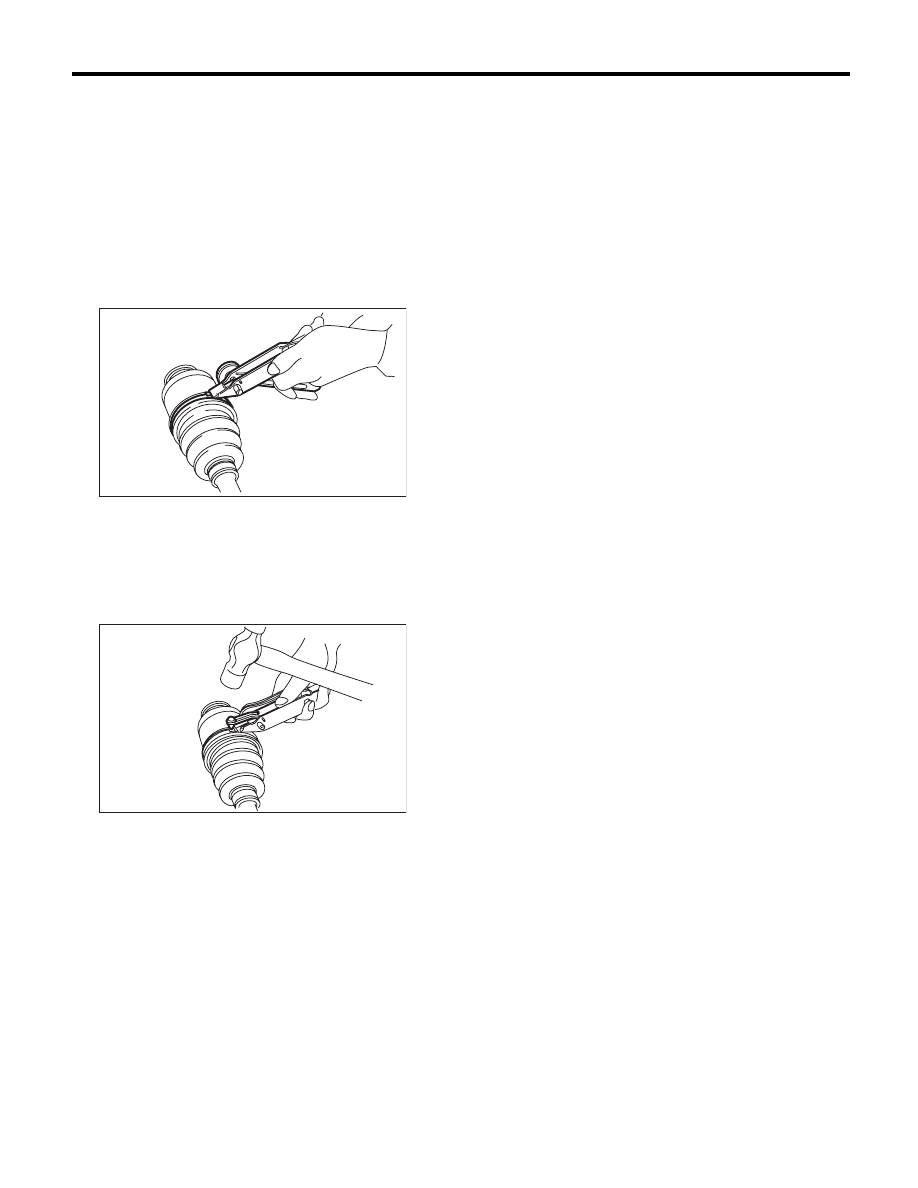

11) Put a new band through the clip and wind twice

in the band groove of the boot.

12) Pinch the end of band with pliers. Hold the clip

and tighten securely.

NOTE:

When tightening boot, use care so that the air with-

in the boot is appropriate.

13) Tighten the band using the ST.

ST

925091000

BAND TIGHTENING TOOL

NOTE:

Tighten the band until it cannot be moved by hand.

14) Tap the clip with the punch provided at the end

of the ST.

ST

925091000

BAND TIGHTENING TOOL

CAUTION:

Tap to an extent that the boot underneath is not

damaged.

15) Cut off the band with an allowance of about 10

mm (0.39 in) left from the clip and bend this allow-

ance over the clip.

CAUTION:

Make sure that the end of the band is in close

contact with clip.

16) Extend and retract the PTJ to provide equal

grease coating.

E: INSPECTION

Check the removed parts for damage, wear, corro-

sion etc. If faulty, repair or replace.

• PTJ (pillow tripod joint)

Check for seizure, corrosion, damage, wear and

excessive play.

• EBJ (high-efficiency compact ball fixed joint)

Check for seizure, corrosion, damage and exces-

sive play.

• Shaft

Check for excessive bending, twisting, damage

and wear.

• Boot

Check for wear, warping, breakage and scratches.

• Grease

Check for discoloration and fluidity.

DS-00132

DS-00133