Subaru Legacy IV (2008 year). Manual - part 874

DI-45

Rear Differential (T-type)

DIFFERENTIALS

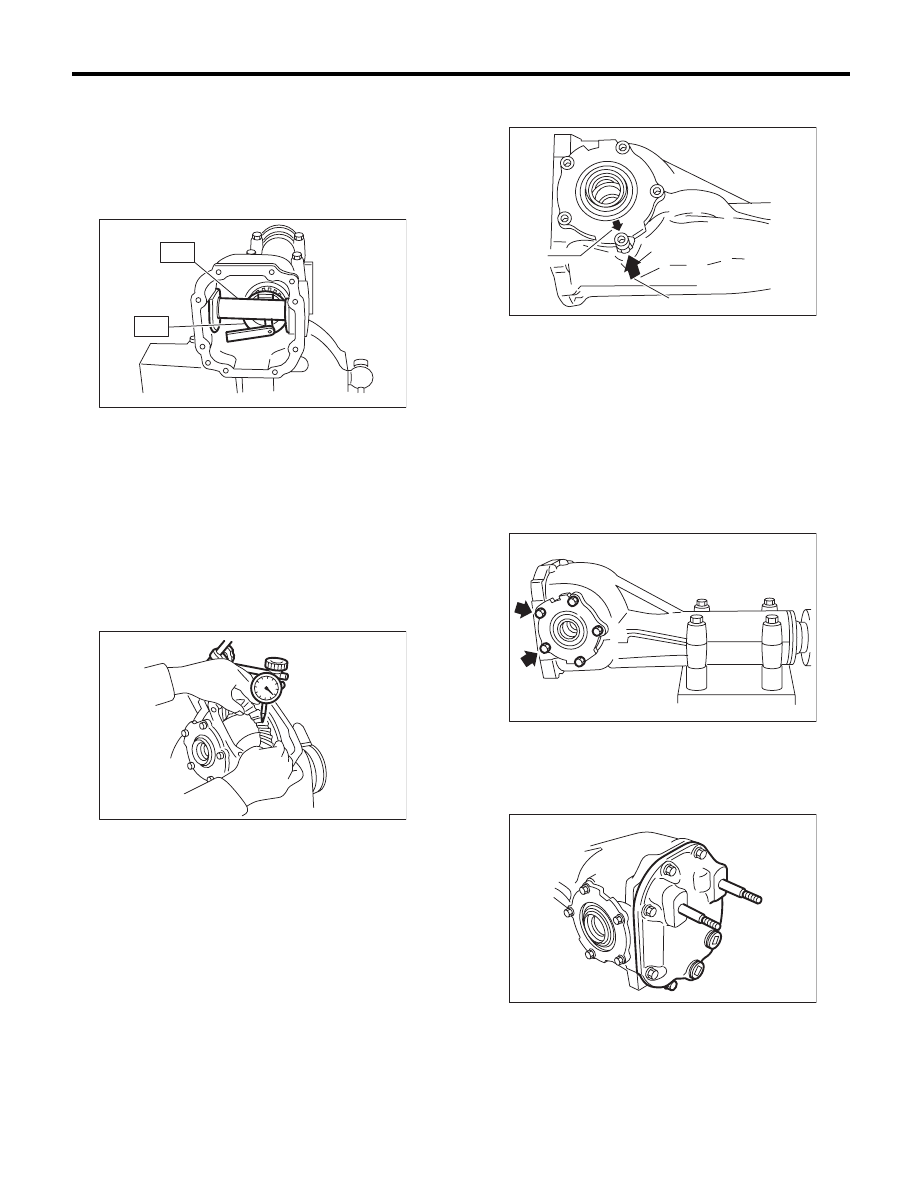

20) If proper tooth contact is not obtained, readjust

the drive pinion height by changing the RH and LH

side retainer shims and the hypoid gear backlash.

(1) Drive pinion height

ST1

398507702

DUMMY SHAFT

ST2

398507701

DIFFERENTIAL CARRIER

GAUGE

T = To + N – (H × 0.01) – 0.20 mm (0.008 in)

Place:

T = Thickness of pinion height adjusting washer

mm (in)

To = Thickness of washer temporarily inserted

mm (in)

N = Clearance of thickness gauge mm (in)

H = Figure marked on drive pinion head

(2) Hypoid gear backlash

Backlash:

0.10 — 0.20 mm (0.004 — 0.008 in)

21) Remove the RH and LH side retainers.

22) Install new O-rings to side retainers of both

sides.

23) Install oil seals to the side retainers on both

sides. <Ref. to DI-88, REPLACEMENT, Rear Dif-

ferential Side Oil Seal.>

24) When installing, align the arrow mark on the dif-

ferential carrier with the mark on the side retainer.

25) Apply liquid gasket to the bolt with arrow marks

and install the side retainer bolt.

Liquid gasket:

THREE BOND 1110B (Part No. K0879Y0020)

or equivalent

Tightening torque:

10.5 N·m (1.1 kgf-m, 7.7 ft-lb)

26) Install the new gasket and rear cover, and tight-

en the bolts to the specified torque.

Tightening torque:

29.5 N·m (3.0 kgf-m, 21.8 ft-lb)

ST2

ST1

DI-00084

DI-00099

(A) Arrow mark (Side retainer side)

(B) Arrow mark (Differential carrier side)

DI-00543

(B)

(A)

DI-00461

DI-00490