Subaru Legacy IV (2008 year). Manual - part 872

DI-37

Rear Differential (T-type)

DIFFERENTIALS

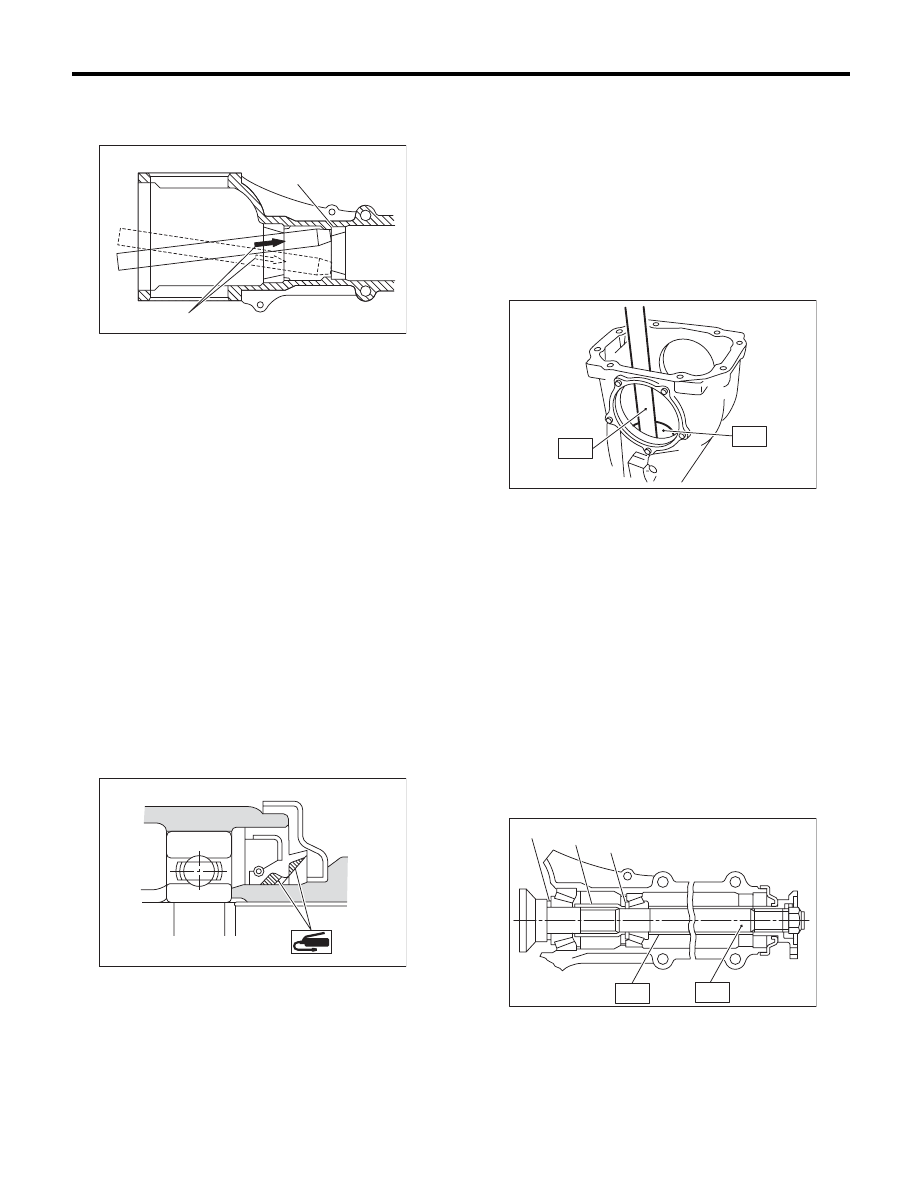

18) When replacing the bearings, hit out the front

bearing cup and rear bearing cup in this order using

a brass bar.

D: ASSEMBLY

1. EXCEPT FOR GT SPEC. B 6MT MODEL

NOTE:

• Assemble in the reverse order of disassembly.

• Check and adjust each part during assembly.

• Keep the shims and washers in order, so that

they are not improperly installed.

• Thoroughly clean the surfaces on which the

shims, washers and bearings are to be installed.

• Apply differential gear oil when installing the

bearings and thrust washers.

• Be careful not to mix up the RH and LH bearing

races.

• Use a new O-ring and gasket.

• Replace the oil seal with a new part at every dis-

assembly.

• Apply differential gear oil to the oil seal lips.

• Be careful not to mix up the differential oil seal

RH and LH.

1) Adjusting preload for front and rear bearings

NOTE:

Adjust the bearing preload between front and rear

bearings with spacer and washer. Pinion height ad-

justing washer is not affected by this adjustment.

The adjustment must not be carried out with oil seal

inserted.

(1) Install the rear bearing race (rear) into the

differential carrier using ST1 and ST2.

ST1

398477701

HANDLE

ST2

398477703

DRIFT 2

(2) Install the rear bearing race (front) into the

differential carrier using ST1 and ST2.

ST1

398477701

HANDLE

ST2

398477702

DRIFT

(3) Insert the ST1 into carrier with the pinion

height adjusting washer and rear bearing cone

fitted onto it.

NOTE:

• If tooth contact is normal in the inspection before

disassembling, verify that the washer is not de-

formed, and then re-use the used washer.

• Use new rear bearing cone.

(4) Install the preload adjusting spacer and

washer, front bearing cone, ST2, companion

flange, washer and self-locking nut.

ST1

398507702

DUMMY SHAFT

ST2

398507703

DUMMY COLLAR

(A) 2 cutout portions along diagonal lines

(B) Tap alternately with a brass bar.

(B)

(A)

DI-00077

DI-00078

(A) Pinion height adjusting washer

(B) Preload adjusting spacer

(C) Preload adjusting washer

ST2

ST1

DI-00079

(B)

(A)

(C)

ST2

ST1

DI-00080