Subaru Legacy IV (2008 year). Manual - part 875

DI-49

Rear Differential (T-type)

DIFFERENTIALS

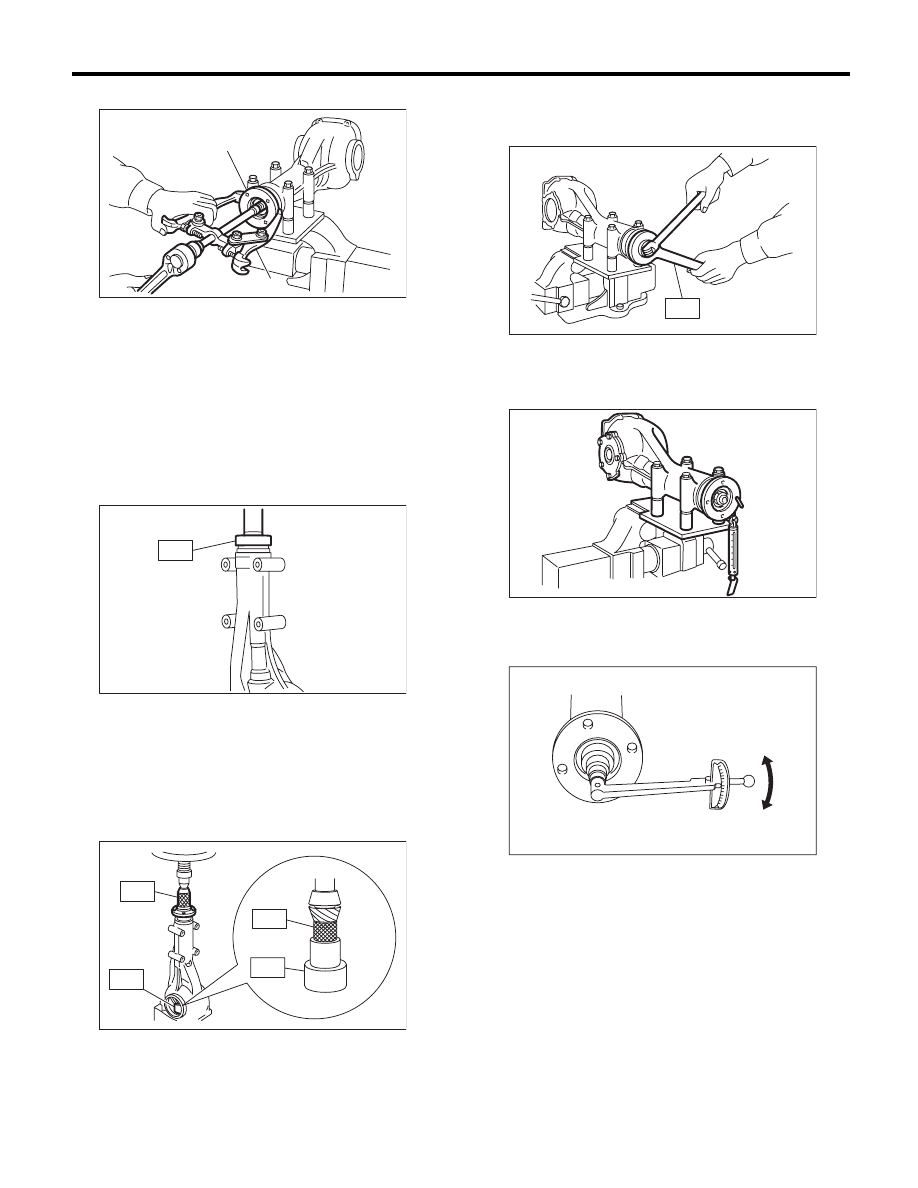

13) Draw out the companion flange with a puller.

14) Install a new oil seal using ST.

NOTE:

• Press-fit until the oil seal end comes 1 mm (0.04

in) inward from end of carrier.

• Apply the differential gear oil between the oil seal

lips.

ST

498447120

INSTALLER

15) Press-fit the companion flange with ST1, ST2

and ST3.

ST1

899874100

INSTALLER

ST2

399780104

WEIGHT

ST3

498937110

HOLDER DRIVE PINION

NOTE:

Be careful not to damage the bearing.

16) Install the self-locking nut. Tighten using the

ST.

ST

498427200

FLANGE WRENCH

17) Check the initial torque and initial load.

Initial load:

24.1 — 38.6 N (2.5 — 3.9 kgf, 5.4 — 8.7 lb)

Initial torque:

0.91 — 1.46 N·m

(0.09 — 0.15 kgf-m, 0.67 — 1.08 ft-lb)

(A) Companion flange

(B) Puller

(B)

(A)

DI-00142

ST

DI-00089

ST3

ST1

ST2

ST2

DI-00323

ST

DI-00071

DI-00117

DI-00481