Subaru Legacy IV (2008 year). Manual - part 852

WT-7

Steel Wheel

WHEEL AND TIRE SYSTEM

3. Steel Wheel

A: REMOVAL

1) Apply the parking brake, and position select le-

ver or shift lever to “P” range (AT model) or “1st

gear” (MT model).

2) Set the shop jacks or a lift to the specified points,

and support the vehicle with its wheels slightly con-

tacting the floor.

3) Loosen the wheel nuts.

4) Raise the vehicle until its wheels are off the

ground using the jack or a lift.

5) Remove the wheel nuts and wheels.

NOTE:

• When removing the wheels, be careful not to

damage the hub bolts.

• Place the wheels with their outer sides facing up-

ward to prevent wheels from being damaged.

B: INSTALLATION

1) Remove dirt from the mating surface of the

wheel and brake rotor.

2) Attach the wheel to the hub by aligning the wheel

bolt holes with the hub bolts.

3) Temporarily attach the wheel nuts to the hub

bolts. (In the case of aluminum wheels, use SUBA-

RU genuine wheel nuts for aluminum wheels.)

4) Tighten the nuts by hand, making sure the wheel

hub hole is aligned correctly to the guide portion of

hub.

5) Tighten the wheel nuts in a diagonal selection to

the specified torque. Use a wheel nut wrench.

Wheel nut tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

CAUTION:

• Tighten the wheel nuts in two or three steps

by gradually increasing the torque on opposing

nuts, until they reach the specified torque.

• Do not push the wrench by foot. Always use

both hands when tightening the nuts.

• Make sure the bolt, nut and the nut seating

surface of the wheel are free from oil.

6) If a wheel is removed for replacement or for re-

pair of a puncture, retighten the wheel nuts to the

specified torque after driving 1,000 km (600 miles).

C: INSPECTION

1) Deformation or damage to the rim may cause air

leakage. Check the rim flange for deformation,

cracks or damage, and repair or replace as neces-

sary.

2) Jack-up the vehicle until wheels clear the floor.

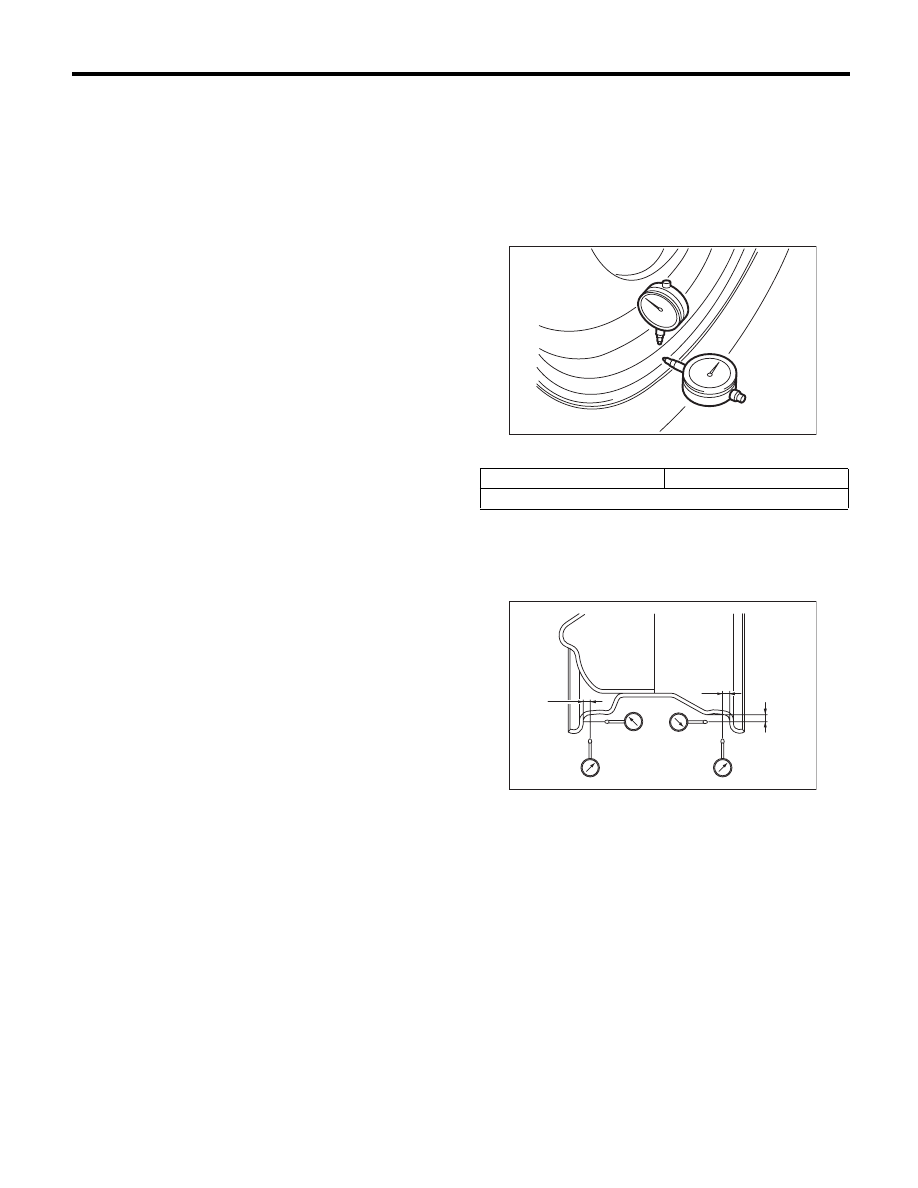

3) Slowly rotate the wheel to check rim “runout” us-

ing a dial gauge.

Rim runout:

4) If the rim runout exceeds specifications, remove

the tire from the wheel and check runout with the

dial gauge attached to positions shown in the fig-

ure.

5) If the measured runout still exceeds specifica-

tions, replace the wheel.

Axial runout limit

Vertical run-out limit

1.5 mm (0.059 in)

(1) Approx. 7 mm (0.28 in)

WT-00004

WT-00005

(1)

(1)

(1)