Subaru Legacy IV (2008 year). Manual - part 841

FS-11

Wheel Alignment

FRONT SUSPENSION

• ADJUSTMENT

When adjusting the toe-in, adjust it to the following

value.

Toe-in:

0

r

2 mm (0

r

0.08 in)

1) Check that the left and right wheel steering an-

gles are within specification.

2) Loosen the left and right side steering tie-rod

lock nuts.

3) Turn the left and right tie-rods by equal amounts

until the toe-in is at the specification.

Both the left and right tie-rods are right-hand

threaded. To increase toe-in, turn both tie-rods

clockwise by equal amount (viewing from the inside

of vehicle).

4) Tighten the tie-rod lock nut.

Tightening torque:

85 N·m (8.7 kgf-m, 62.7 ft-lb)

NOTE:

Check and correct the tie-rod boot if twisted.

6. REAR WHEEL TOE-IN

• INSPECTION

Toe-in:

OUTBACK model

–3 — 0 mm (–0.12 — 0 in)

Except for OUTBACK model

0

r

3 mm (0

r

0.12 in)

Refer to FRONT WHEEL TOE-IN for rear toe-in in-

spection procedures.

<Ref. to FS-10, FRONT WHEEL TOE-IN, INSPEC-

TION, Wheel Alignment.>

• ADJUSTMENT

When adjusting, adjust it to the following value.

Toe-in:

OUTBACK model

–3 — 0 mm (–0.12 — 0 in)

Except for OUTBACK model

0

r

2 mm (0

r

0.08 in)

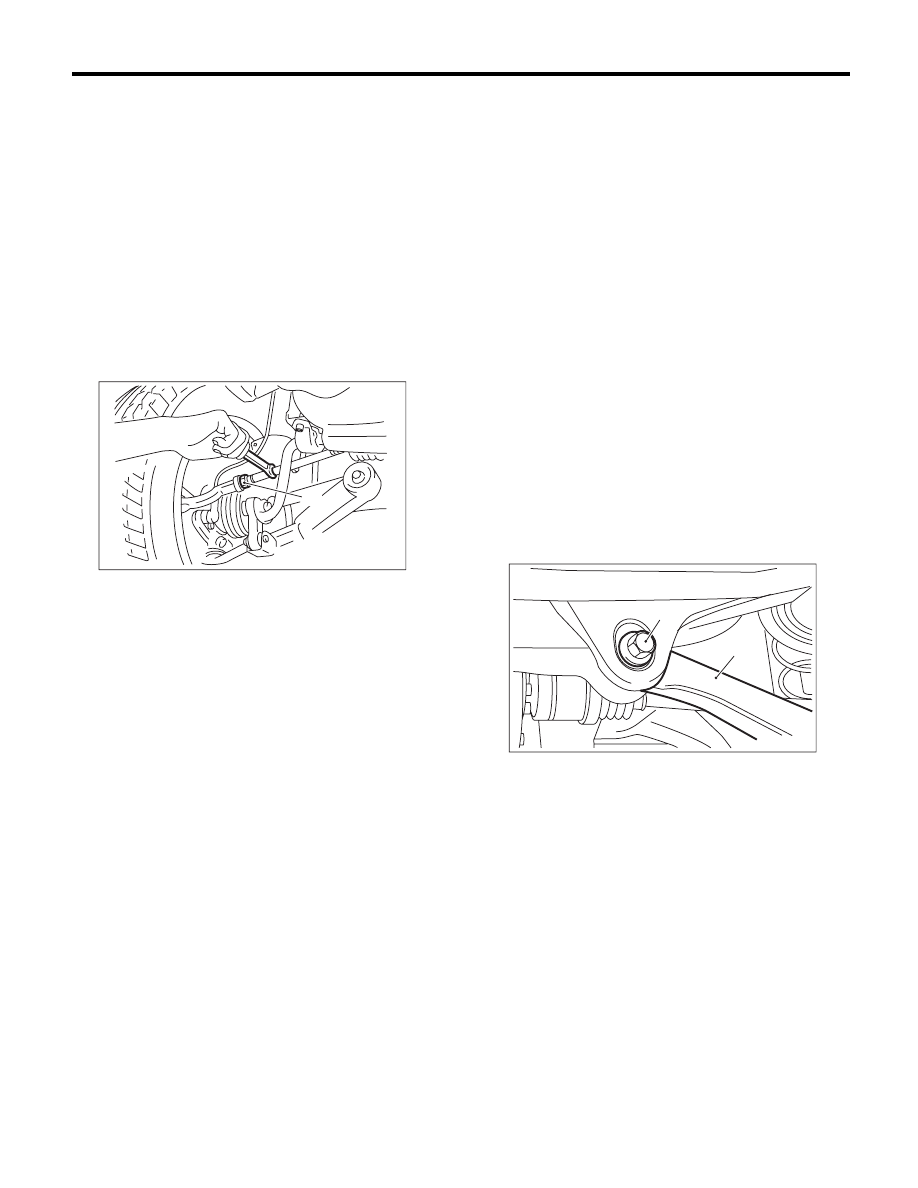

1) Loosen the self-locking nut on the inner side of

rear link.

NOTE:

When loosening or tightening the adjusting bolt,

hold the bolt head and turn the self-locking nut.

(1) Lock nut

FS-00014

(1)

(1) Adjusting bolt

(2) Rear link

FS-00103

(1)

(2)