Subaru Legacy IV (2008 year). Manual - part 794

5MT-72

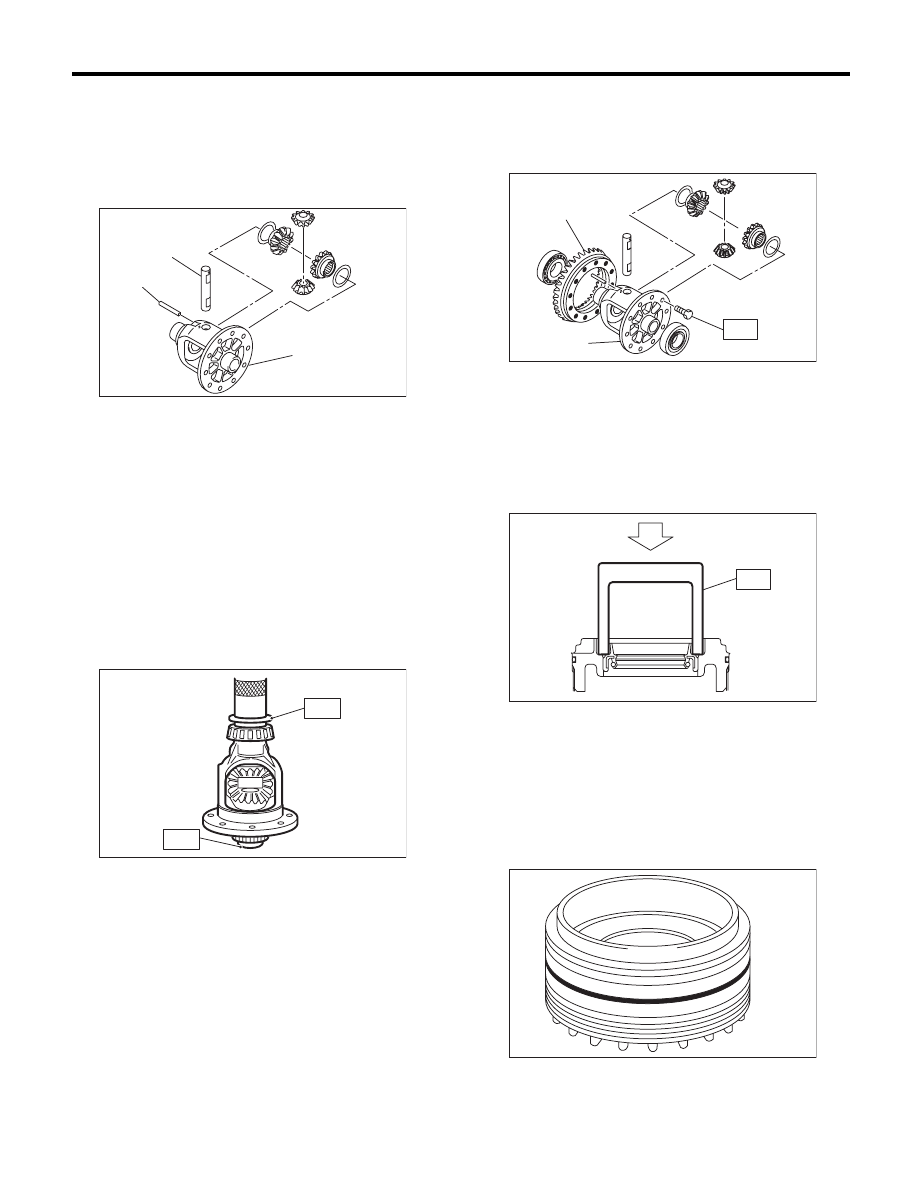

Front Differential Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL

3) Align the pinion shaft and differential case with

each hole, and drive the straight pin into the holes

from the hypoid driven gear using ST.

NOTE:

Lock the straight pin after installing.

ST

899904100

REMOVER

4) Install the roller bearing to differential case.

CAUTION:

Do not apply pressure in excess of 10 kN (1 ton,

1.1 US ton, 1.0 Imp ton).

NOTE:

Be careful because the roller bearing outer races

are used as a set.

ST1

499277100

BUSHING 1-2 INSTALLER

ST2

398497701

ADAPTER

5) Install the hypoid driven gear to the differential

case using twelve bolts.

Tightening torque:

T: 62 N·m (6.3 kgf-m, 45.7 ft-lb)

2. SIDE RETAINER

1) Install a new oil seal.

ST

18675AA000

DIFFERENTIAL SIDE OIL

SEAL INSTALLER

CAUTION:

• When press-fitting the oil seal to the side re-

tainer, tap with a plastic hammer etc. to press

in.

• Do not use a press.

2) Install a new O-ring.

NOTE:

Do not stretch or damage the O-ring.

(A) Pinion shaft

(B) Differential case

(C) Straight pin

MT-00286

(A)

(C)

(B)

MT-00287

ST1

ST2

(A) Hypoid driven gear

(B) Differential case

MT-00993

(B)

(A)

T

MT-00289

ST

MT-00279