Subaru Legacy IV (2008 year). Manual - part 792

5MT-64

Drive Pinion Shaft Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL

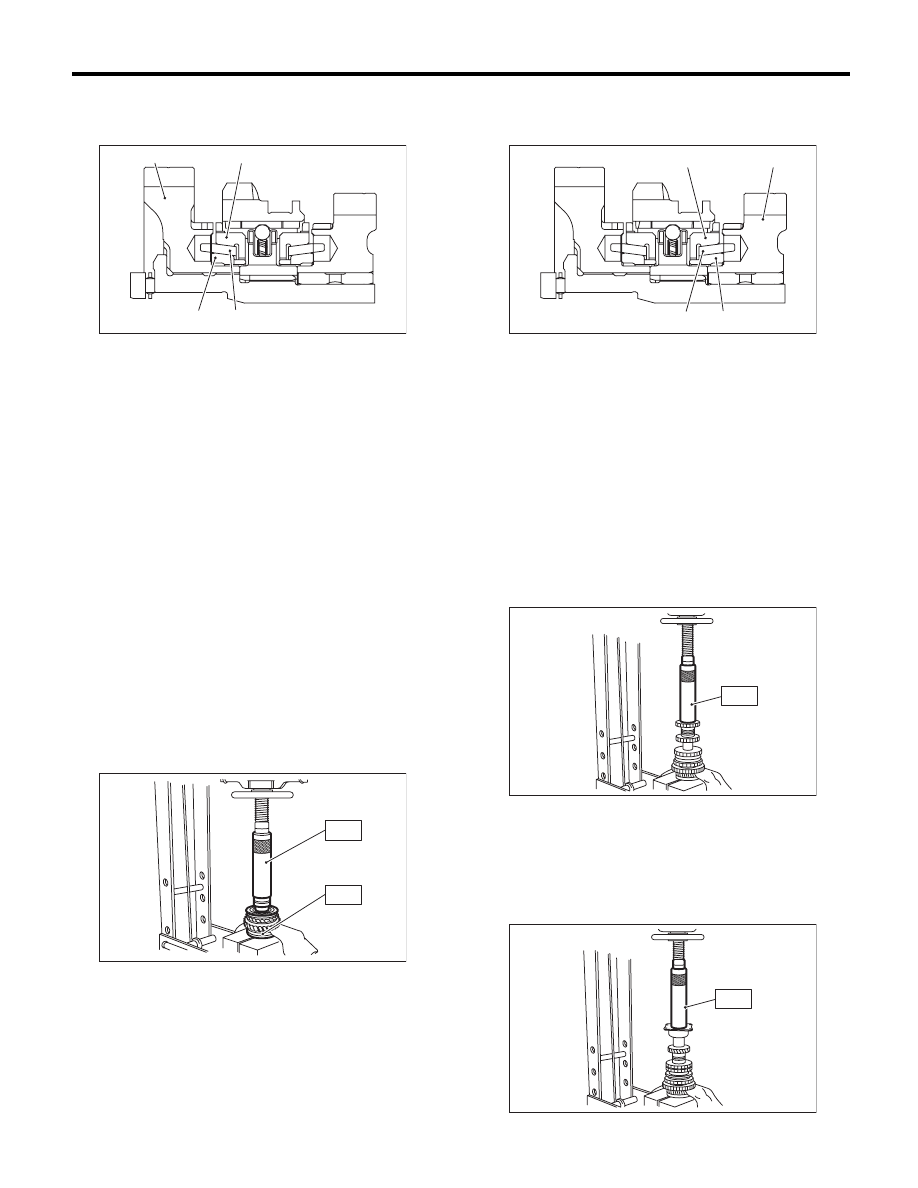

3) Install the 1st driven gear, inner baulk ring, syn-

chro cone and outer baulk ring, and gear & hub as-

sembly onto driven shaft.

NOTE:

• Take care to install the gear & hub assembly in

proper direction.

• Align the baulk ring and gear & hub assembly

with the key groove.

4) Install the 2nd driven gear bushing onto driven

shaft using ST1, ST2 and a press.

CAUTION:

Do not apply pressure in excess of 10 kN (1 ton,

1.1 US ton, 1.0 Imp ton).

NOTE:

• Attach a cloth to the end of the driven shaft to

prevent damage.

• When press fitting, align the oil holes of the shaft

and bushing

ST1

499277200

INSTALLER

ST2

499587000

INSTALLER

5) Install the 2nd driven gear, inner baulk ring, syn-

chro cone and outer baulk ring, and insert them

onto driven shaft.

6) After installing key on driven shaft, install the

3rd-4th driven gear using an ST and a press.

CAUTION:

Do not apply pressure in excess of 10 kN (1 ton,

1.1 US ton, 1.0 Imp ton).

NOTE:

Align the groove in baulk ring with the insert.

ST

499277200

INSTALLER

7) Install a set of roller bearings onto the driven

shaft using ST and a press.

CAUTION:

Do not apply pressure in excess of 10 kN (1 ton,

1.1 US ton, 1.0 Imp ton).

ST

499277200

INSTALLER

(A) 1st driven gear

(B) Inner baulk ring

(C) Synchro cone

(D) Outer baulk ring

(D)

(C)

(B)

(A)

MT-01634

MT-00253

ST1

ST2

(A) 2nd driven gear

(B) Inner baulk ring

(C) Synchro cone

(D) Outer baulk ring

(A)

(B)

(C)

(D)

MT-01633

MT-00255

ST

MT-00256

ST