Subaru Legacy IV (2008 year). Manual - part 791

5MT-60

Drive Pinion Shaft Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL

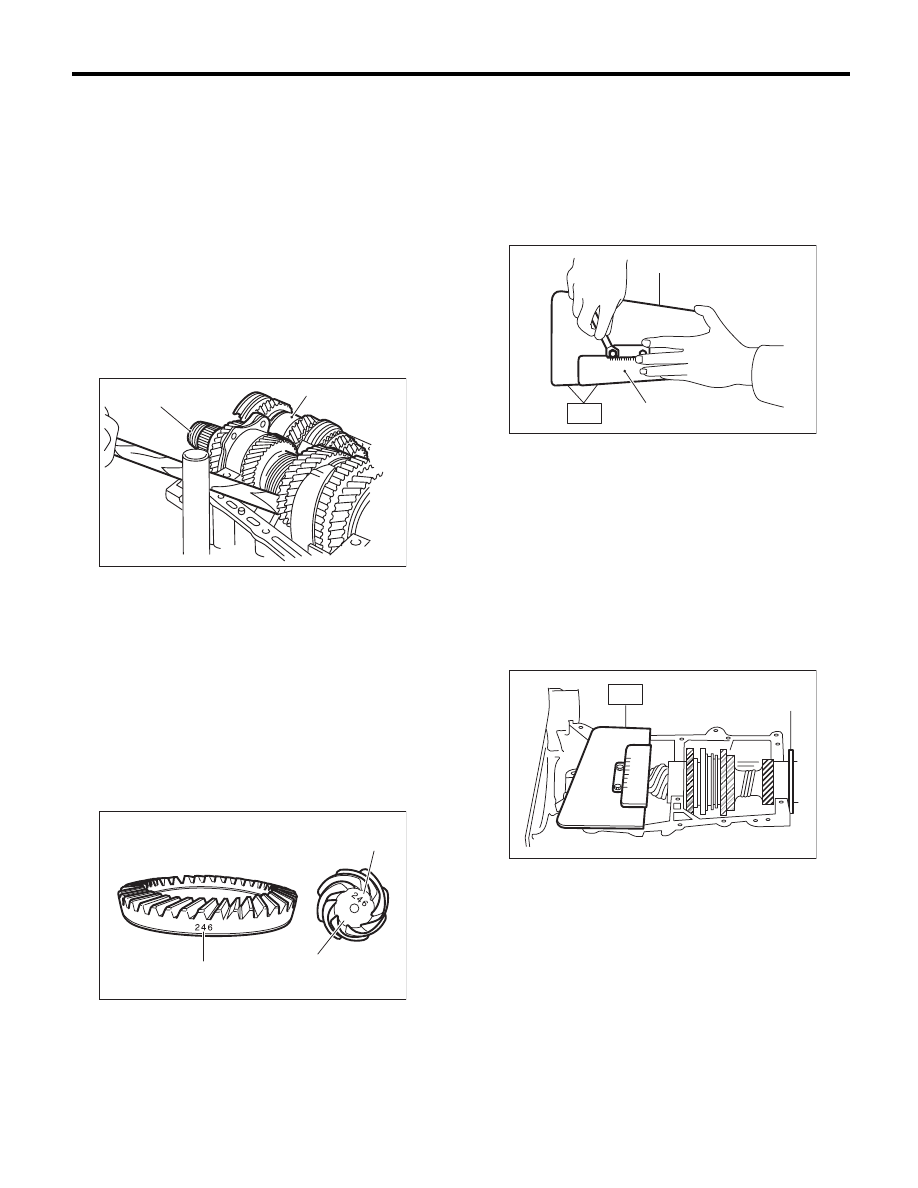

16.Drive Pinion Shaft Assembly

A: REMOVAL

1) Remove the manual transmission assembly

from the vehicle. <Ref. to 5MT-24, REMOVAL,

Manual Transmission Assembly.>

2) Remove the transfer case together with the ex-

tension case assembly. <Ref. to 5MT-38, REMOV-

AL, Transfer Case and Extension Case

Assembly.>

3) Remove the transmission case. <Ref. to 5MT-

51, REMOVAL, Transmission Case.>

4) Remove the drive pinion shaft assembly.

NOTE:

Use a hammer handle, etc. to remove if too tight.

B: INSTALLATION

1) Remove the front differential assembly.

2) Alignment marks/numbers on hypoid gear set:

The number (A) on top of the drive pinion, and the

number on the hypoid driven gear are set numbers

for the two gears. Use a pair having the same num-

bers.

The figure (B) below shows a number for shim ad-

justment. If no number is shown, the value is zero.

3) Place the drive pinion shaft assembly on trans-

mission main case RH without shim and tighten the

bearing mounting bolts.

4) Check and adjust the ST.

NOTE:

• Loosen the two bolts and adjust so that the scale

indicates 0.5 correctly when the plate end and the

scale end are on the same level.

• Tighten the two bolts.

ST

499917500

DRIVE PINION GAUGE

ASSY

5) Position the ST by inserting the knock pin of ST

into the knock hole of transmission case.

ST

499917500

DRIVE PINION GAUGE

ASSY

6) Slide the drive pinion gauge scale with finger tip

and read the value at the point where it matches

with the end face of drive pinion.

ST

499917500

DRIVE PINION GAUGE

ASSY

7) The thickness of shim shall be determined by

adding the value indicated on drive pinion to the

value indicated on the ST. (Add if the number on

drive pinion is prefixed by +, and subtract if the

number is prefixed by –.)

ST

499917500

DRIVE PINION GAUGE

ASSY

(A) Main shaft ASSY for single range

(B) Drive pinion shaft ASSY

(A) Set number

(B) Number for shim adjustment

MT-00161

( A )

( B )

MT-00990

(A)

(B)

(A)

+0.1

(A) Plate

(B) Scale

(A) Adjust the clearance to zero without shim.

MT-00242

(A)

(B)

ST

MT-00243

(A)

ST