Subaru Legacy IV (2008 year). Manual - part 741

5AT-88

Drive Pinion Shaft Assembly

AUTOMATIC TRANSMISSION

C: DISASSEMBLY

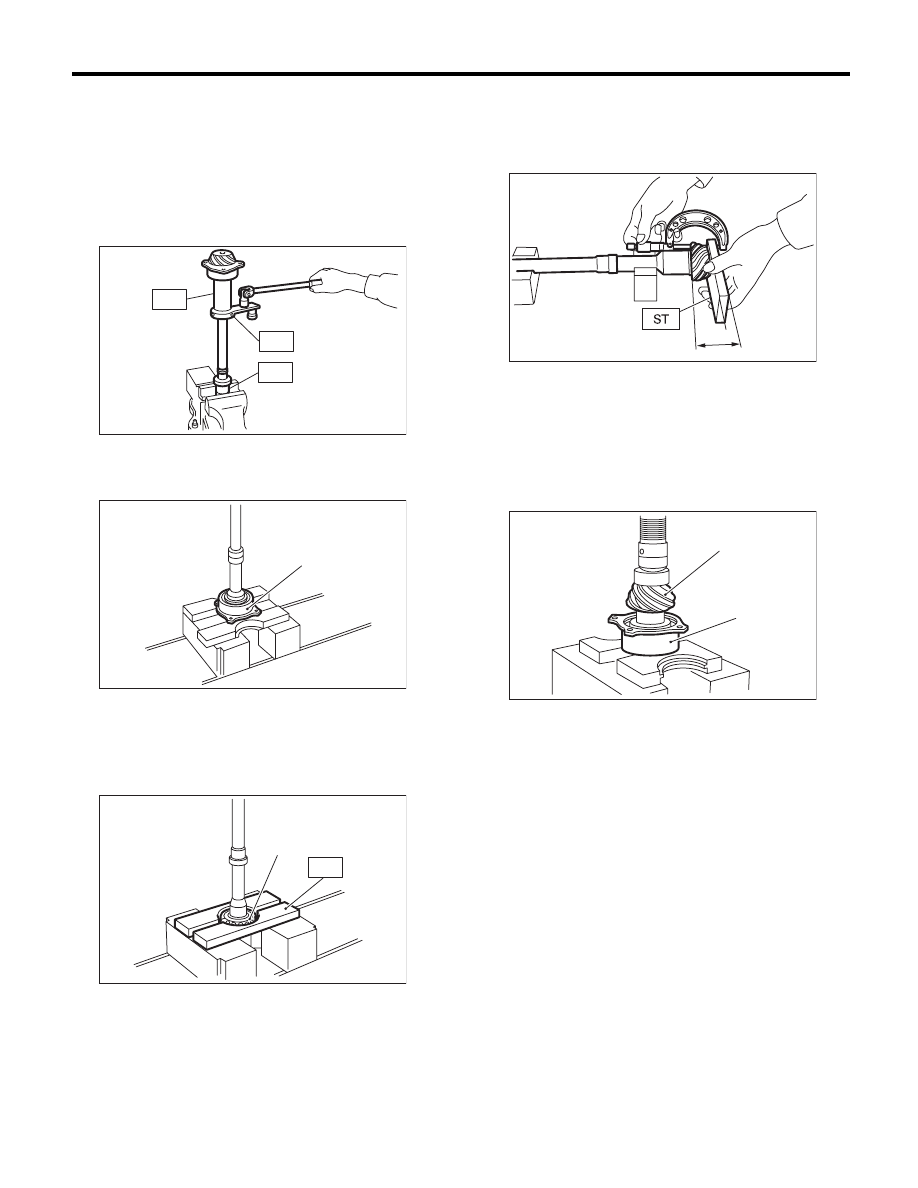

1) Flatten the lock nut tab, and then remove the

lock nut while holding the rear spline part of the

shaft using ST1 and ST2. Pull out the drive pinion

collar.

ST1

18667AA010

HOLDER

ST2

499787700

WRENCH

ST3

499787500

ADAPTER

2) Remove the O-ring.

3) Separate the roller bearing and outer race from

shaft using a press.

4) Separate the front roller bearing from the shaft

using a press and the ST.

ST

498517000

REPLACER

D: ASSEMBLY

1) Measure the dimension “A” of the drive pinion

shaft.

ST

398643600

GAUGE

2) Using a press, press-fit the new roller bearing

into the specified position.

NOTE:

If excessive force is applied to roller bearing, the

roller bearing will not turn easily.

3) After fitting a new O-ring to the shaft, attach the

drive pinion collar to the shaft.

(A) Outer race

(A) Front roller bearing

AT-00197

ST1

ST3

ST2

AT-00198

(A)

AT-00199

(A)

ST

A Measured value

(A) Drive pinion shaft

(B) Roller bearing

A

AT-00200

AT-00201

(B)

(A)