Subaru Legacy IV (2008 year). Manual - part 740

5AT-84

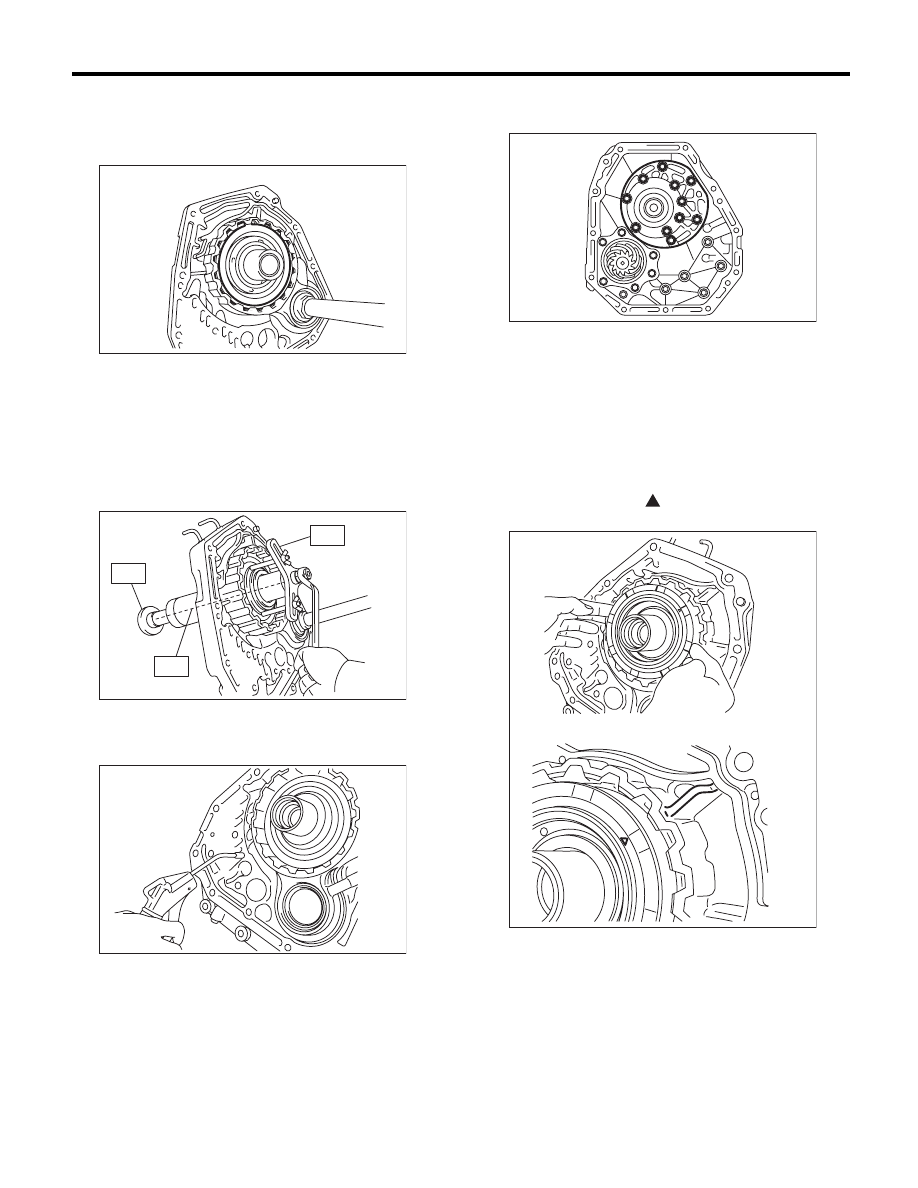

Oil Pump Cover

AUTOMATIC TRANSMISSION

C: DISASSEMBLY

1. FRONT BRAKE

1) Remove the snap ring.

2) Remove the retainer plate, drive plate and driven

plate.

3) Using the ST1, ST2 and ST3, remove the snap

ring.

ST1

18762AA000

COMPRESSOR SPECIAL

TOOL

ST2

18765AA000

COMPRESSOR SUPPORT

ST3

18763AA000

COMPRESSOR SHAFT

4) Remove the retainer and return spring.

5) Remove the front brake piston using com-

pressed air.

6) Remove the D-ring from front brake piston.

2. OIL PUMP

1) Take out the oil pump housing.

2) Take out the oil pump body.

D: ASSEMBLY

1. FRONT BRAKE

1) Apply ATF to D-ring, and then install it to the

front brake piston.

2) Install the front brake piston to oil pump cover.

NOTE:

Install by aligning the “

” mark on front brake pis-

ton surface with the oil pump cover rib.

3) Install the retainer and return spring.

AT-01980

AT-01981

ST1

ST2

ST3

AT-02349

AT-01982

AT-02350