Subaru Legacy IV (2008 year). Manual - part 685

4AT-88

Oil Pump Housing

AUTOMATIC TRANSMISSION

(3) If the depth and/or side clearance are not

within the specification, replace the oil pump ro-

tor assembly.

Measure the total end play and adjust it to be

within specifications. <Ref. to 4AT-88, AD-

JUSTMENT, Oil Pump Housing.>

F: ADJUSTMENT

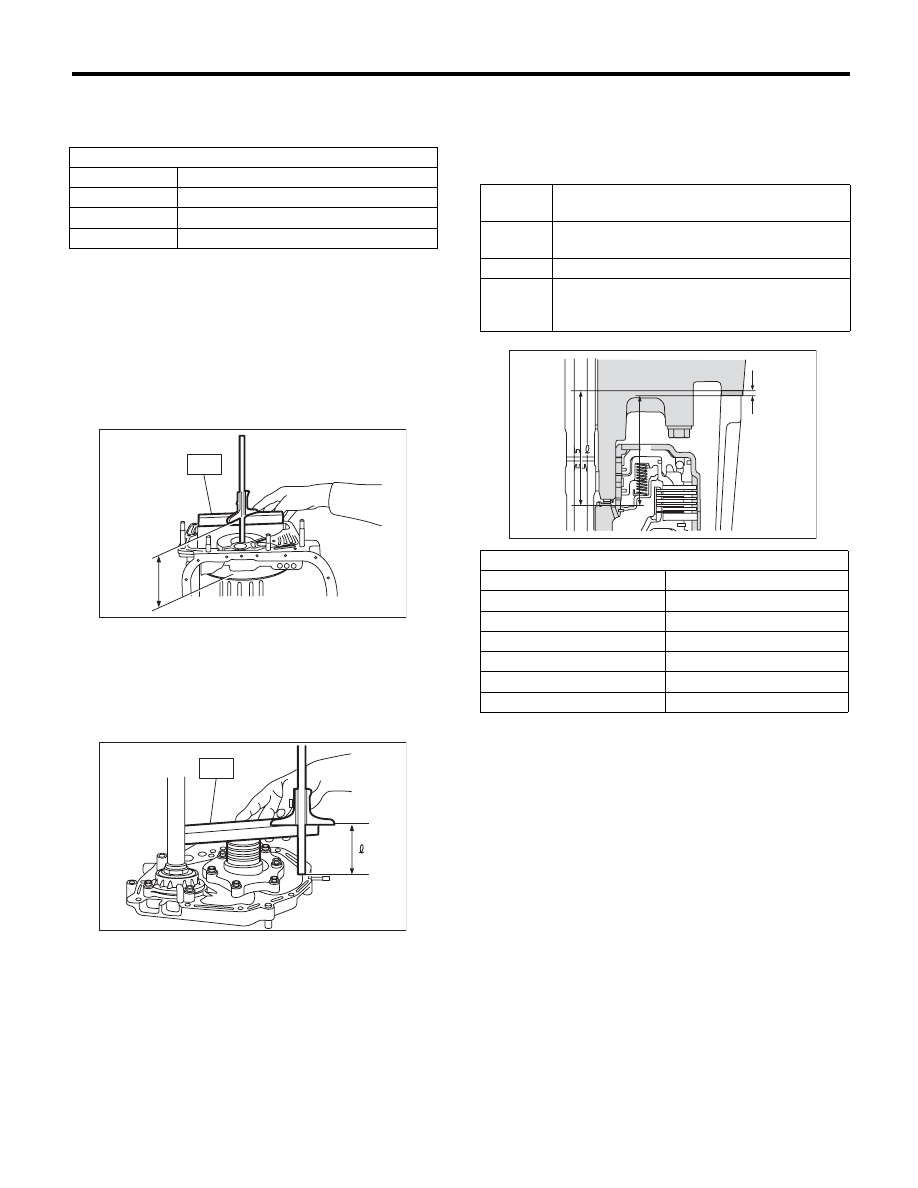

1) Using the ST, measure the length “L”, from the

mating surface of the transmission to the recessed

portion of the high clutch drum.

ST

398643600

GAUGE

2) Using the ST, measure the length “L” from the oil

pump housing mating surface to the top surface of

the oil pump cover with the thrust needle bearing.

ST

398643600

GAUGE

3) Calculation of total end play

Select a suitable bearing race from the table below

so that clearance C will be within 0.25 to 0.55 mm

(0.0098 to 0.0217 in).

C = (L + G) –

2

4) After completing the total end play adjustment,

insert the bearing race into the high clutch race. Ap-

ply vaseline, and install the thrust needle bearing to

the oil pump cover.

5) After correctly installing the new gasket to the

case mating surface, carefully install the oil pump

housing assembly. Be careful to avoid hitting the

drive pinion against the inside of case.

6) Install both parts with dowel pins aligned. Make

sure there is no clearance at the mating surface.

Oil pump rotor assembly

Part No.

Thickness mm (in)

15008AA060

11.37 — 11.38 (0.4476 — 0.4480)

15008AA070

11.38 — 11.39 (0.4480 — 0.4484)

15008AA080

11.39 — 11.40 (0.4484 — 0.4488)

L Measured value

2 Measured value

AT-00194

L

ST

AT-00195

ST

C

Clearance between concave section of high

clutch and end of clutch drum support

L

Length from case mating surface to the concave

portion of the high clutch

G

Gasket thickness [0.28 mm (0.0110 in)]

2

Height from the oil pump housing mating sur-

face to the upper surface of the oil pump cover

with the thrust needle bearing.

Thrust needle bearing

Part No.

Thickness mm (in)

806528050

4.1 (0.161)

806528060

4.3 (0.169)

806528070

4.5 (0.177)

806528080

4.7 (0.185)

806528090

4.9 (0.193)

806528100

5.1 (0.201)

AT-00196

G

L