Subaru Legacy IV (2008 year). Manual - part 684

4AT-84

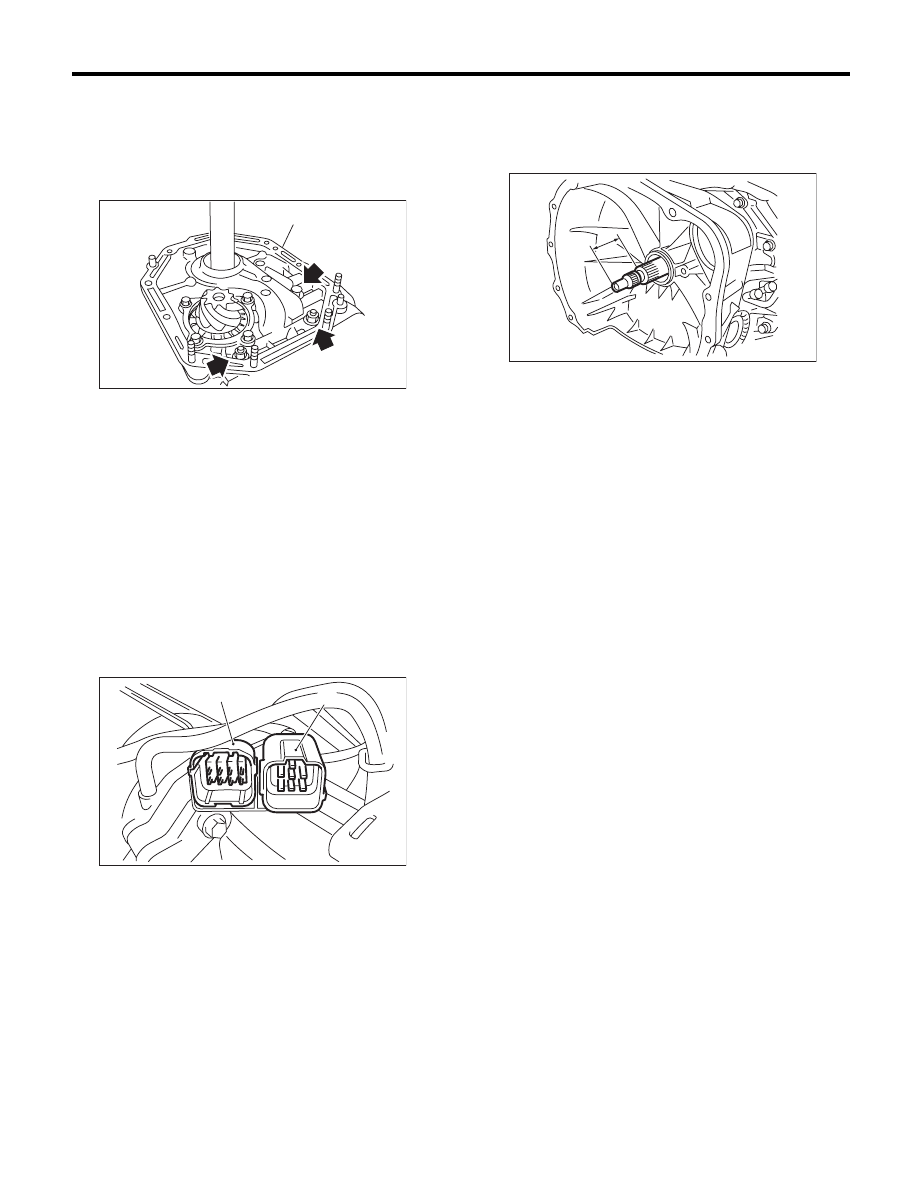

Oil Pump Housing

AUTOMATIC TRANSMISSION

B: INSTALLATION

1) Secure the oil pump housing with two nuts and a

bolt.

Tightening torque:

42 N·m (4.3 kgf-m, 31.0 ft-lb)

2) Install the converter case to the transmission

case assembly. <Ref. to 4AT-81, INSTALLATION,

Converter Case.>

3) Install the reduction driven gear. <Ref. to 4AT-

75, INSTALLATION, Reduction Driven Gear.>

4) Install the reduction drive gear. <Ref. to 4AT-77,

INSTALLATION, Reduction Drive Gear.>

5) Join the transmission case and the extension

case, and then install the rear vehicle speed sen-

sor. <Ref. to 4AT-68, INSTALLATION, Extension

Case.>

6) Insert the inhibitor switch connector and trans-

mission harness connector onto the stay.

7) Install the ATF cooler pipe. <Ref. to 4AT-63, IN-

STALLATION, ATF Cooler Pipe and Hose.>

8) Install the oil charge pipe together with an O-

ring. <Ref. to 4AT-66, INSTALLATION, Oil Charge

Pipe.>

9) Insert the input shaft while rotating it lightly by

hand, and then check the amount of protrusion.

Normal protrusion A:

50 — 55 mm (1.97 — 2.17 in)

10) Install the torque converter clutch assembly.

<Ref. to 4AT-67, INSTALLATION, Torque Convert-

er Clutch Assembly.>

11) Install the transmission assembly to the vehi-

cle. <Ref. to 4AT-38, INSTALLATION, Automatic

Transmission Assembly.>

(A) Oil pump housing

(A) Transmission harness connectors

(B) Inhibitor switch connector

AT-01035

(A)

AT-01351

(B)

(A)

A Measured value

AT-03204

A