Subaru Legacy IV (2008 year). Manual - part 278

ME(H4DOTC)-92

Cylinder Block

MECHANICAL

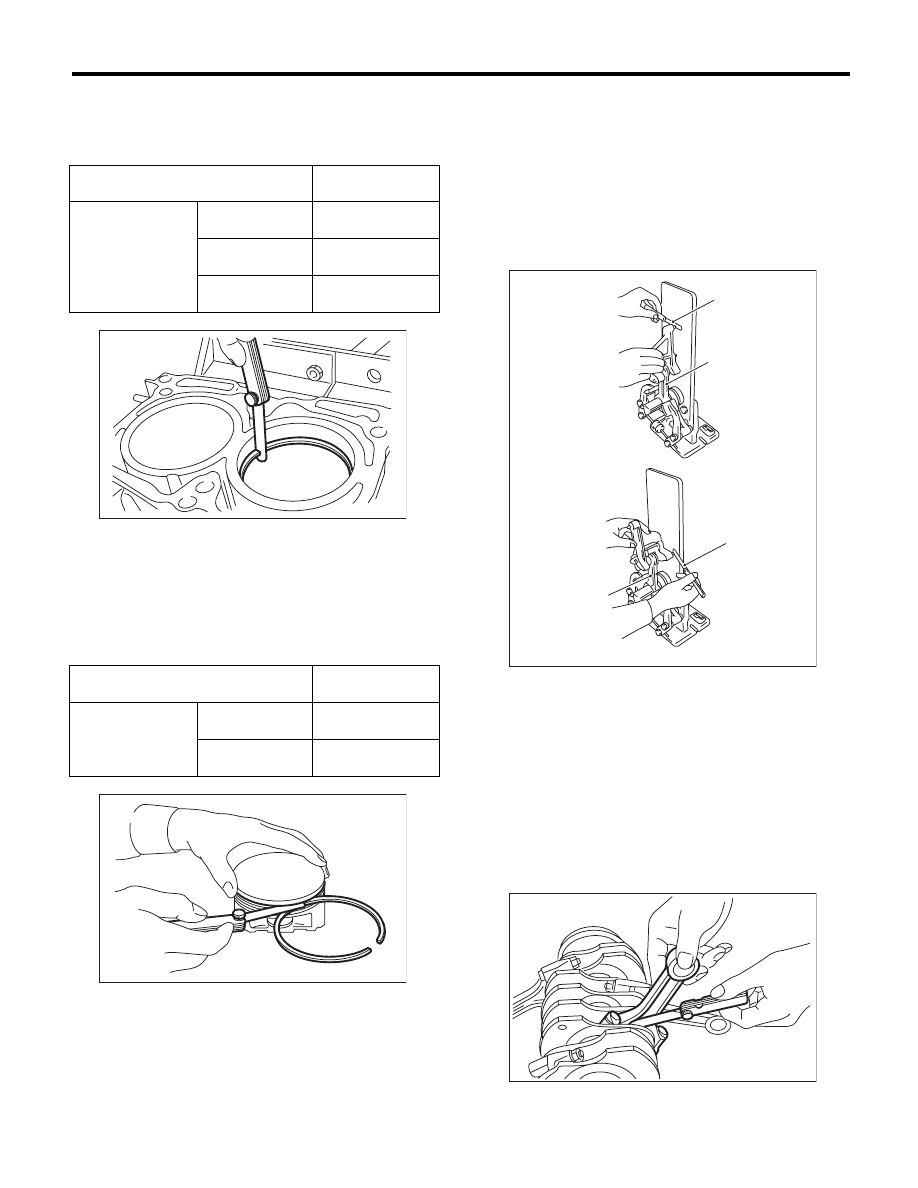

2) Using the piston, insert the piston ring and oil

ring into the cylinder so that they are perpendicular

to the cylinder wall, and measure the piston ring

gap with a thickness gauge.

3) Fit the piston ring straight into the piston ring

groove, then measure the clearance between pis-

ton ring and piston ring groove with a thickness

gauge.

NOTE:

Before measuring the clearance, clean the piston

ring groove and piston ring.

5. CONNECTING ROD

1) Replace the connecting rod, if the large or small

end thrust surface is damaged.

2) Check for bend or twist using a connecting rod

aligner. Replace the connecting rod if the bend or

twist exceeds the limit.

Limit of bend or twist per 100 mm (3.94 in) in

length:

0.10 mm (0.0039 in)

3) Install the connecting rod fitted with bearing to

the crankshaft, and measure the thrust clearance

using a thickness gauge. If the thrust clearance ex-

ceeds the standard or uneven wear is found, re-

place the connecting rod.

Connecting rod thrust clearance:

Standard

0.070 — 0.330 mm (0.0028 — 0.0130 in)

4) Inspect the connecting rod bearing for scar,

peeling, seizure, melting, wear, etc.

Standard

mm (in)

Piston ring gap

Top ring

0.20 — 0.25

(0.0079 — 0.0098)

Second ring

0.37 — 0.52

(0.015 — 0.020)

Oil ring rail

0.20 — 0.50

(0.0079 — 0.0197)

Standard

mm (in)

Clearance between

piston ring and

piston ring groove

Top ring

0.040 — 0.080

(0.0016 — 0.0031)

Second ring

0.030 — 0.070

(0.0012 — 0.0028)

ME-00177

ME-00178

(A) Thickness gauge

(B) Connecting rod

( A )

( A )

( B )

( B )

ME-00179

ME-00180