Subaru Legacy IV (2008 year). Manual - part 276

ME(H4DOTC)-84

Cylinder Block

MECHANICAL

(7) Set the parts so that the #3 and #4 cylinders

are on the upper side. Following the same pro-

cedures as used for #1 and #2 cylinders, install

the pistons and piston pins.

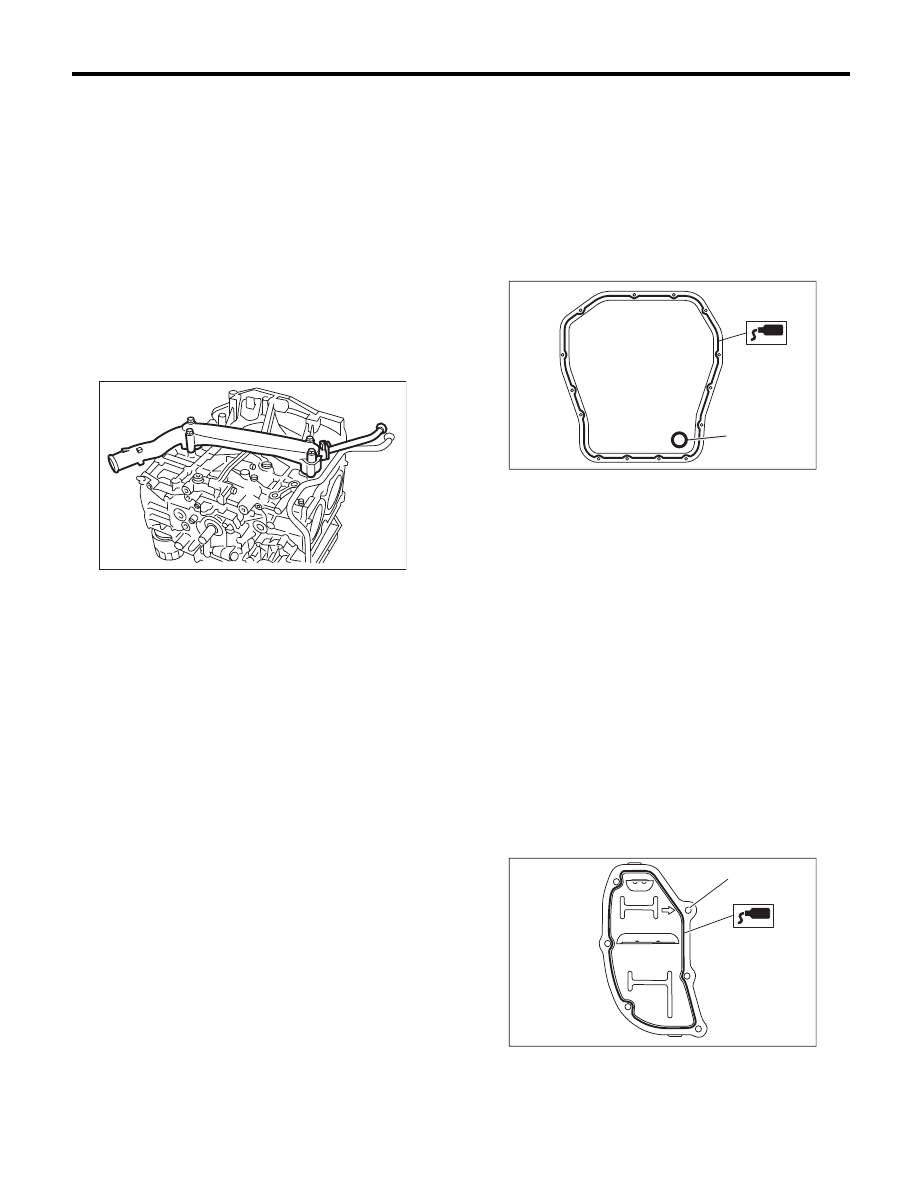

(8) Install the service hole cover.

NOTE:

Use new O-rings.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

22) Install the water pipe assembly.

NOTE:

Use new O-rings.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

23) Install the water tank pipe assembly.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

24) Install the baffle plate.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

25) Install the oil strainer.

NOTE:

Use new O-rings.

Tightening torque:

10 N·m (1.0 kgf-m, 7.2 ft-lb)

26) Tighten the oil strainer stay together with the

baffle plate.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

27) Apply liquid gasket to the mating surfaces of oil

pan, and install the oil pan.

NOTE:

Install within 5 minutes after applying liquid gasket.

Liquid gasket:

THREE BOND 1217G (Part No. K0877Y0100)

or equivalent

Tightening torque:

5 N·m (0.5 kgf-m, 3.7 ft-lb)

28) Apply liquid gasket to the mating surfaces of

the oil separator cover and the threaded portion of

bolt (A) shown in the figure (when reusing the bolt),

and then install the oil separator cover.

NOTE:

• Install within 5 minutes after applying liquid gas-

ket.

• Use new oil separator cover.

Liquid gasket:

Mating surface

THREE BOND 1217G (Part No.

K0877Y0100) or equivalent

Bolt thread (A) (when reusing the bolt)

THREE BOND 1324 (Part No. 004403042) or

equivalent

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

ME-00300

(A) Gasket

LU-02353

(A)

ME-03333

(A)