Subaru Legacy IV (2008 year). Manual - part 277

ME(H4DOTC)-88

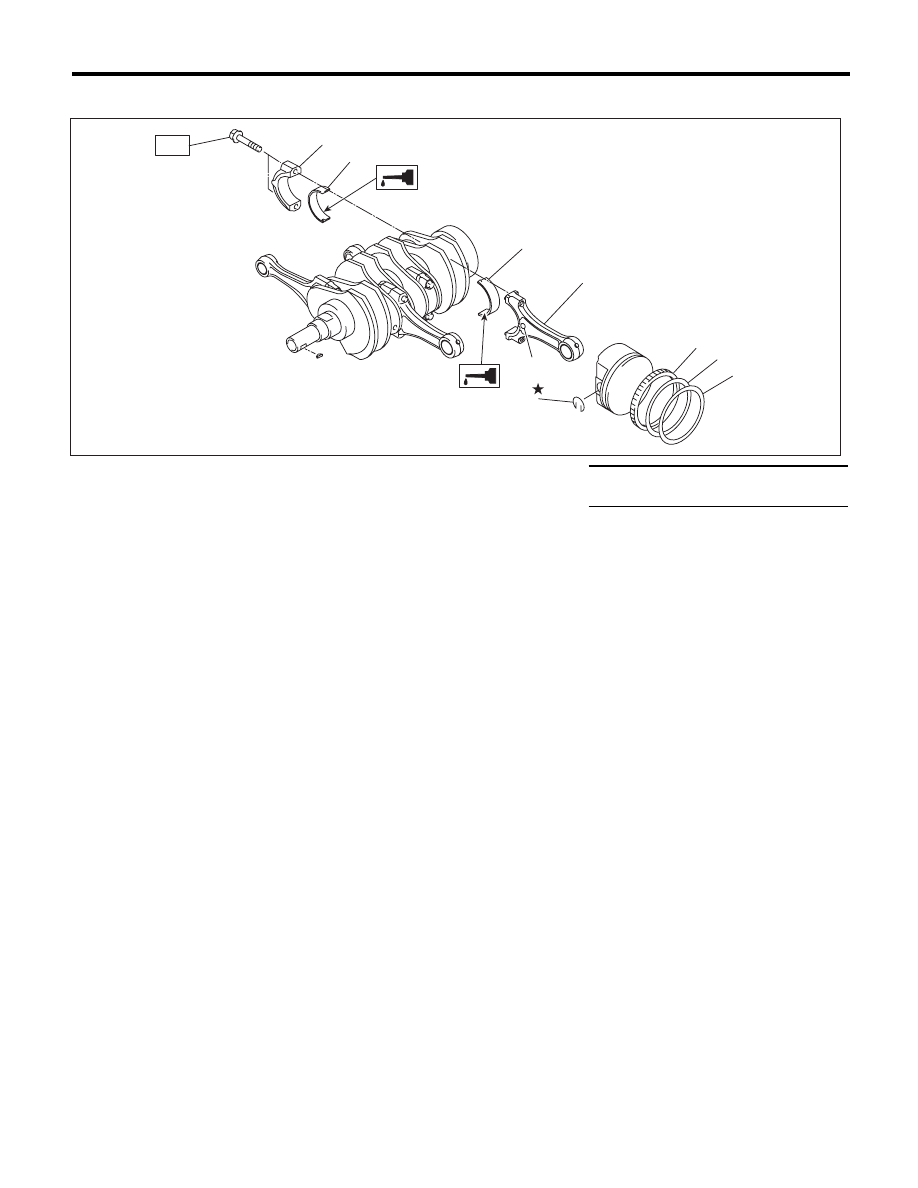

Cylinder Block

MECHANICAL

D: ASSEMBLY

1) Apply oil to the surface of the connecting rod

bearings, and install the connecting rod bearings

on connecting rods and connecting rod caps.

2) Position each connecting rod with a side mark

facing forward, and install it.

3) Attach the connecting rod cap, and tighten with

the connecting rod bolt. Make sure the arrow mark

on connecting rod cap facing front during installa-

tion.

NOTE:

• Each connecting rod has its own mating cap.

Make sure that they are assembled correctly by

checking their matching number.

• When tightening the connecting rod nuts, apply

oil on the threads.

Tightening torque:

52 N·m (5.3 kgf-m, 38.4 ft-lb)

4) Install the oil ring upper rail, expander and lower

rail by hand.

5) Install the second ring and top ring using piston

ring expander.

NOTE:

Assemble so that the piston ring mark “R” faces the

top side of the piston.

(1)

Connecting rod bearing

(5)

Second ring

Tightening torque:N·m (kgf-m, ft-lb)

(2)

Connecting rod

(6)

Top ring

T: 52 (5.3, 38.4)

(3)

Connecting rod cap

(7)

Snap ring

(4)

Oil ring

(8)

Side mark

ME-02985

(1)

(1)

(7)

(4)

(5)

(6)

(3)

T

(2)

(8)