Subaru Legacy IV (2008 year). Manual - part 270

ME(H4DOTC)-60

Camshaft

MECHANICAL

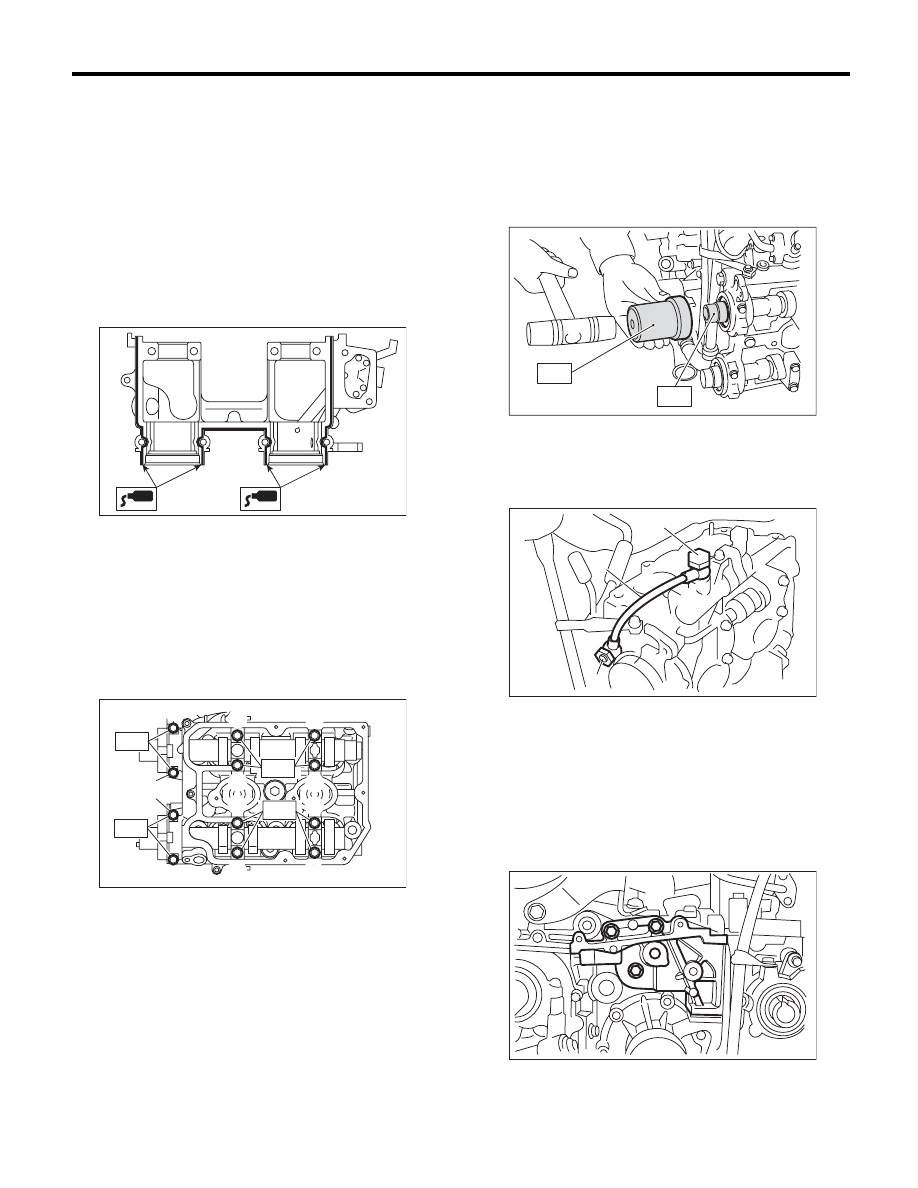

2) Install the camshaft cap.

(1) Apply small amount of liquid gasket to the

mating surface of cap.

NOTE:

• Install within 5 minutes after applying liquid gas-

ket.

• Do not apply liquid gasket excessively. Applying

excessively may cause excess gasket to come out

and flow toward oil seal, resulting in oil leak.

Liquid gasket:

THREE BOND 1217G (Part No. K0877Y0100)

or equivalent

(2) Apply a thin coat of engine oil to the cap

journal surface, and install the camshaft cap to

the camshaft.

(3) Gradually tighten the camshaft cap in at

least two stages in alphabetical order shown in

the figure, and then tighten to specified torque.

Tightening torque:

T1: 9.75 N·m (1.0 kgf-m, 7.2 ft-lb)

T2: 20 N·m (2.0 kgf-m, 14.8 ft-lb)

(4) After tightening the camshaft cap, ensure

the camshaft rotates only slightly while holding

it at base circle.

3) Apply a coat of engine oil to the camshaft oil seal

periphery and oil seal lips, then install the oil seal

on the camshaft using ST1 and ST2.

NOTE:

Use a new oil seal.

ST1

499587600

OIL SEAL INSTALLER

ST2

499597200

OIL SEAL GUIDE

4) Install the oil pipe to the front camshaft cap using

the union screw without filter (without protrusion).

Tightening torque:

29 N·m (3.0 kgf-m, 21.4 ft-lb)

5) Similarly, install the parts on right-hand side.

6) Install the tensioner bracket.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

ME-00773

ME-02379

(G)

(C)

(A)

(K)

(L)

T1

(F)

(E)

T2

T2

(B)

(J)

(H)

(D)

(I)

T1

(A) Union screw with filter (with protrusion)

(B) Union screw without filter (without protrusion)

(C) Oil pipe

ME-00116

ST1

ST2

(A)

(B)

ME-03555

(C)

ME-00105