Subaru Legacy IV (2008 year). Manual - part 268

ME(H4DOTC)-52

Timing Belt

MECHANICAL

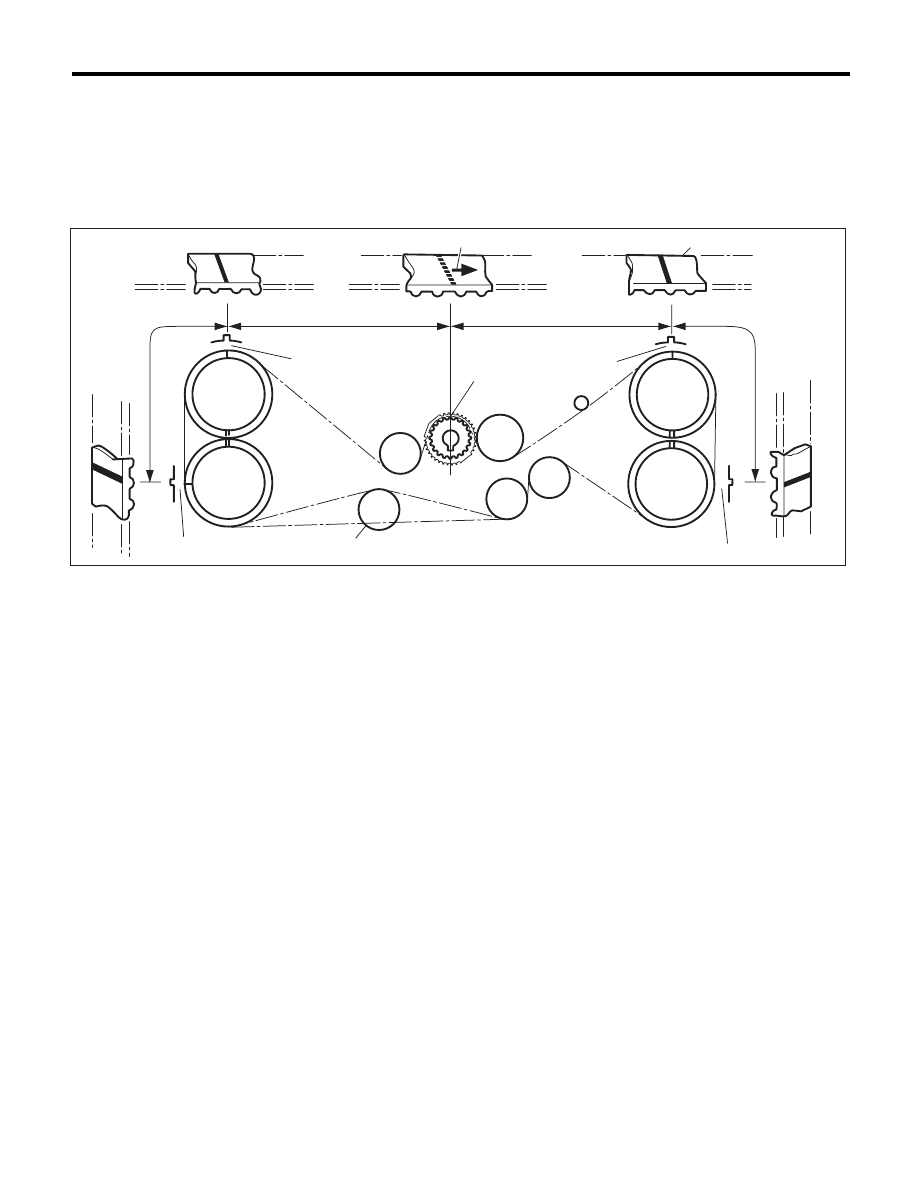

8) Install the timing belt.

Align the alignment mark on the timing belt with marks on the sprockets in the alphabetical order shown in

the figure. While aligning marks, position the timing belt properly.

CAUTION:

• Disengagement of more than three timing belt teeth may result in interference between the valve

and piston.

• Make sure that the direction of belt rotation is correct.

(1)

Arrow mark

(4)

54.5-teeth length

(6)

28-teeth length

(2)

Timing belt

(5)

51-teeth length

(7)

Install it in the end

(3)

28-teeth length

ME-03137

(1)

(2)

(5)

(6)

(4)

(D)

(A)

(C)

(B)

(E)

(3)

RH-IN

RH-EX

LH-EX

LH-IN

(7)