Subaru Legacy IV (2008 year). Manual - part 271

ME(H4DOTC)-64

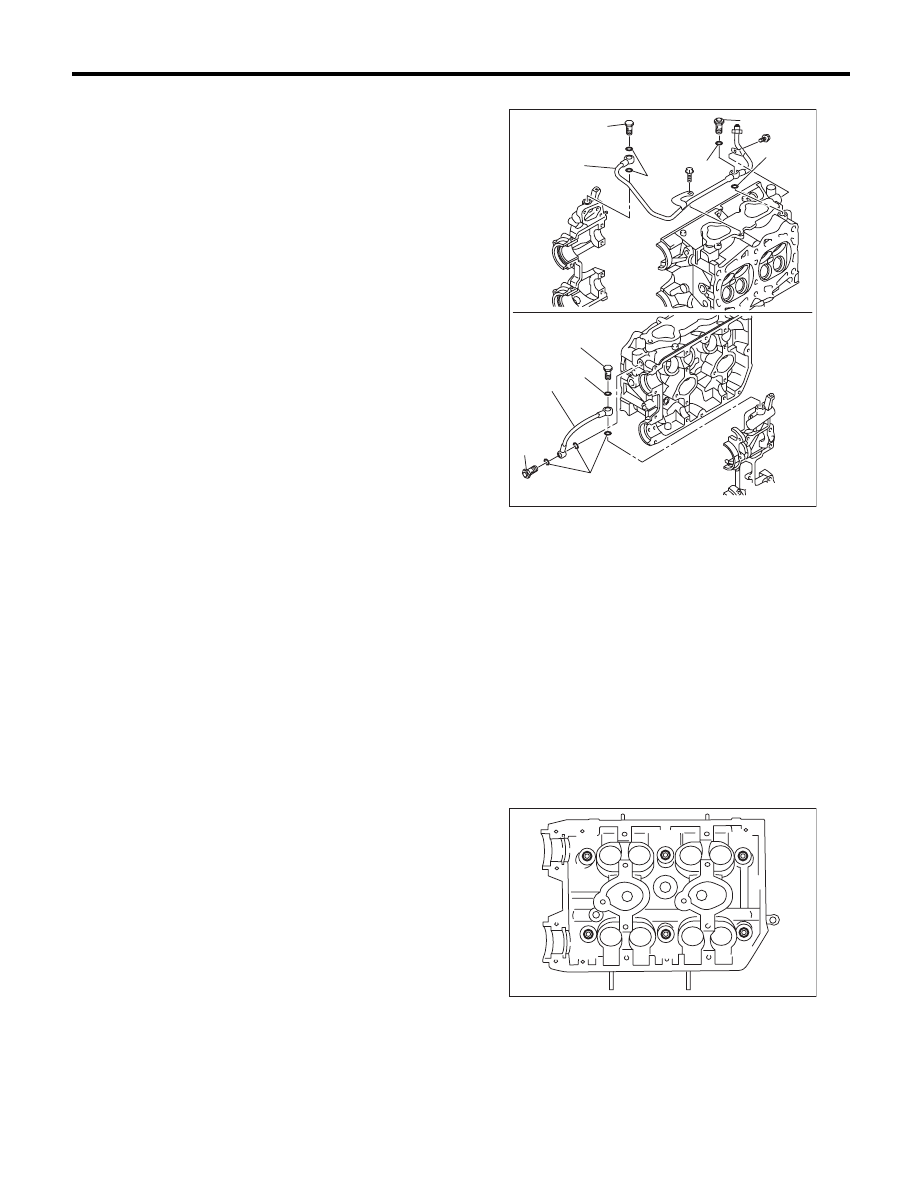

Cylinder Head

MECHANICAL

19.Cylinder Head

A: REMOVAL

NOTE:

• When replacing the single part, perform the work

with the engine installed to body. Refer to “Valve

Clearance” for preparation procedures. <Ref. to

ME(H4DOTC)-26, INSPECTION, Valve Clear-

ance.>

• When performing the work with the engine in-

stalled to body, the following parts must also be re-

moved/installed.

• Center exhaust pipe <Ref. to EX(H4DOTC)-7,

REMOVAL, Center Exhaust Pipe.> <Ref. to

EX(H4DOTC)-9, INSTALLATION, Center Ex-

haust Pipe.>

• Turbocharger <Ref. to IN(H4DOTC)-14, RE-

MOVAL, Turbocharger.> <Ref. to IN(H4DOTC)-

15, INSTALLATION, Turbocharger.>

• Joint pipe <Ref. to EX(H4DOTC)-11, REMOV-

AL, Joint Pipe.> <Ref. to EX(H4DOTC)-11, IN-

STALLATION, Joint Pipe.>

• Front exhaust pipe <Ref. to EX(H4DOTC)-5,

REMOVAL, Front Exhaust Pipe.> <Ref. to

EX(H4DOTC)-6, INSTALLATION, Front Exhaust

Pipe.>

1) Remove the V-belts. <Ref. to ME(H4DOTC)-41,

REMOVAL, V-belt.>

2) Remove the intake manifold. <Ref. to

FU(H4DOTC)-16, REMOVAL, Intake Manifold.>

3) Remove the crank pulley. <Ref. to

ME(H4DOTC)-44, REMOVAL, Crank Pulley.>

4) Remove the timing belt cover. <Ref. to

ME(H4DOTC)-46, REMOVAL, Timing Belt Cover.>

5) Remove the timing belt. <Ref. to ME(H4DOTC)-

47, REMOVAL, Timing Belt.>

6) Remove the cam sprocket. <Ref. to

ME(H4DOTC)-56, REMOVAL, Cam Sprocket.>

7) Remove the bolt which installs the A/C compres-

sor bracket on cylinder head.

8) Remove the secondary air combination valve.

<Ref. to EC(H4DOTC)-22, REMOVAL, Secondary

Air Combination Valve.>

9) Remove the oil pipe.

10) Remove the camshaft. <Ref. to ME(H4DOTC)-

58, REMOVAL, Camshaft.>

11) Remove the oil level gauge guide. (LH side

only)

12) Remove the cylinder head bolts in alphabetical

order shown in the figure.

NOTE:

Leave the bolts (A) and (D) engaged by three or

four threads to prevent the cylinder head from fall-

ing.

(A) Union screw with filter (with protrusion)

(B) Union screw without filter (without protrusion)

(C) Oil pipe

(D) Gasket

ME-03919

(A)

(B)

(C)

(D)

(D)

(A)

(B)

(C)

(D)

(D)

(D)

ME-00122

(B)

(C)

(D)

(E)

(F)

(A)