Subaru Legacy IV (2008 year). Manual - part 261

ME(H4DOTC)-24

Engine Oil Pressure

MECHANICAL

6. Engine Oil Pressure

A: INSPECTION

1) Remove the collector cover.

2) Disconnect the ground cable from the battery.

3) Remove the oil pressure switch. <Ref. to

LU(H4SO)-20, REMOVAL, Oil Pressure Switch.>

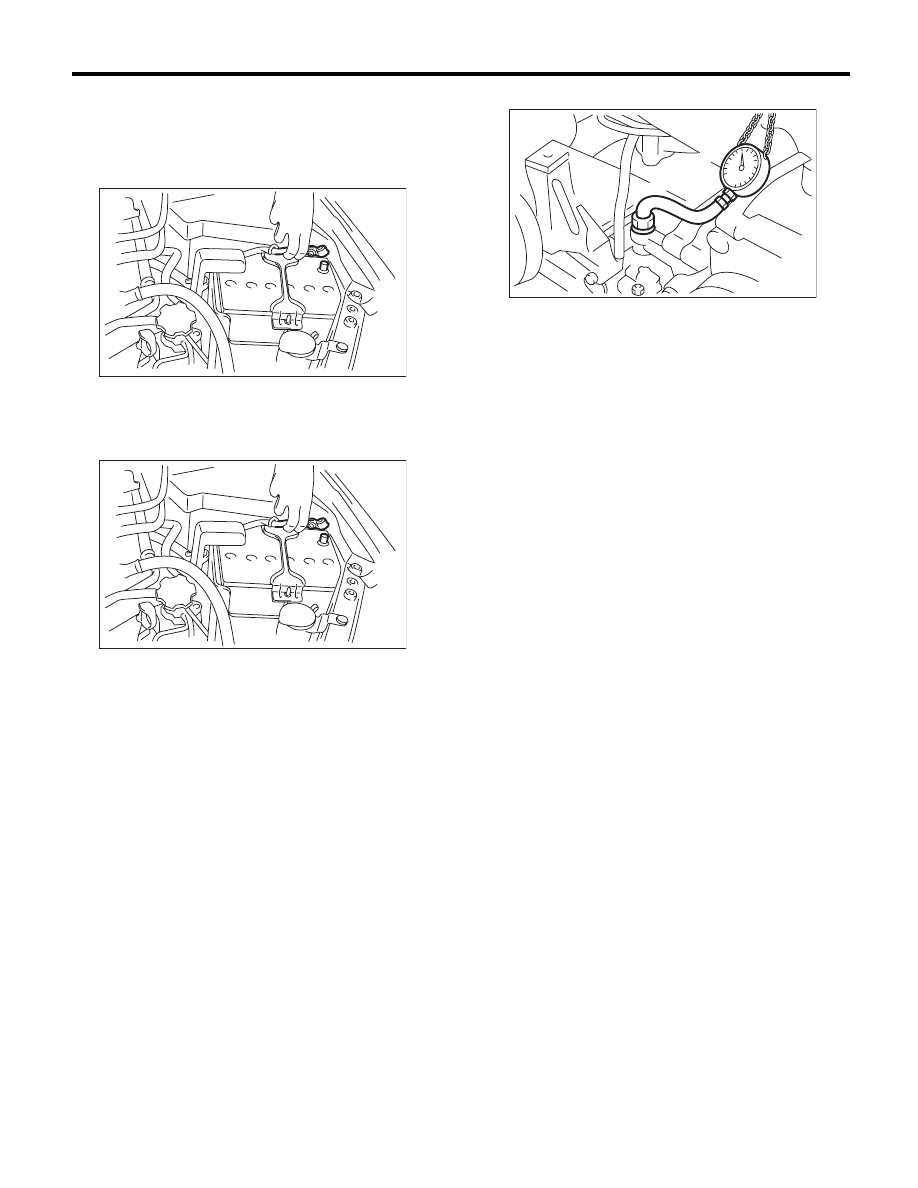

4) Connect the oil pressure gauge to cylinder block.

5) Connect the ground cable to battery.

6) Start the engine, and measure the oil pressure.

Oil pressure:

Standard

98 kPa (1.0 kgf/cm

2

, 14 psi) or more

(at 600 rpm)

294 kPa (3.0 kgf/cm

2

, 43 psi) or more

(at 5,000 rpm)

• If the oil pressure is out of specification, check oil

pump, oil filter and lubrication line. <Ref. to

LU(H4SO)-24, INSPECTION, Engine Lubrication

System Trouble in General.>

• If the oil pressure warning light is ON and oil

pressure is within specification, check the oil pres-

sure switch. <Ref. to LU(H4SO)-24, INSPECTION,

Engine Lubrication System Trouble in General.>

NOTE:

Standard value is based on an engine oil tempera-

ture of 80°C (176°F).

7) After measuring the oil pressure, install the oil

pressure switch. <Ref. to LU(H4SO)-20, INSTAL-

LATION, Oil Pressure Switch.>

IN-00203

IN-00203

ME-03698